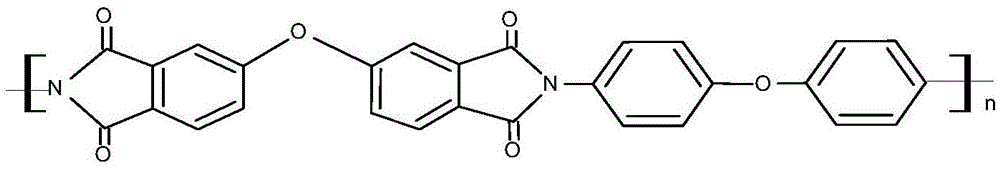

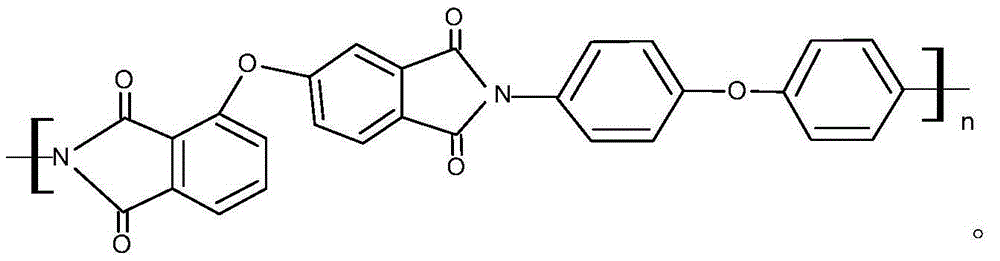

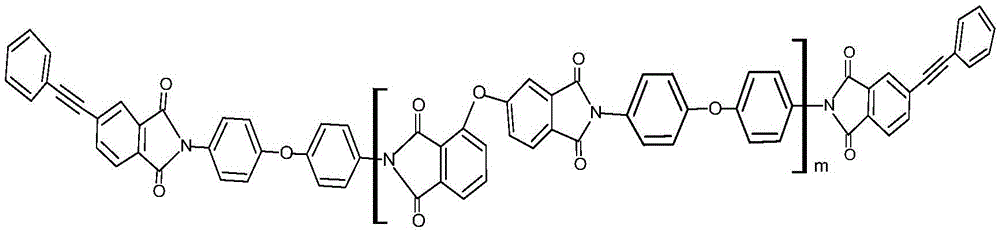

A kind of preparation method of soluble and meltable copolymerization polyimide molding compound

A polyimide and polyamic acid technology, which is applied in the field of preparation of soluble and fusible copolymerized polyimide, can solve the problems of reducing polymer solubility and thermoplasticity, affecting processing performance, etc., so as to improve thermal performance, The processing performance is equivalent, and the effect of easy filtration and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Put 160g (0.8mol) of 4,4'-diaminodiphenyl ether, 21.6g (0.2mol) of p-phenylenediamine and 2200ml of diphenylenediamine into a 5000ml four-neck round bottom flask equipped with a mechanical stirrer, a thermometer, and a nitrogen inlet and outlet. Methyl acetamide, stir to dissolve completely, then add 310g (1mol) 2,3,3′,4′-diphenyl ether tetracarboxylic dianhydride, react at room temperature for 4 hours to obtain a polyamic acid solution, add 1050g acetic anhydride , triethylamine 260g and xylene 210g, continue to react for 1.0 to complete the imidization reaction, filter the precipitated polyimide powder, then wash with 1000ml acetone three times, filter, and bake at 50-80°C for 1-2 hours , and then heat-treated at 220°C to 280°C for 2 to 5 hours to obtain a copolymerized polyimide with a yield of 92% and an inherent viscosity of 75ml / g. The polyimide molded a plastic sample at 350°C / 30MPa, and the performance indicators of the plastic sample are shown in Table-1 below:...

Embodiment 2

[0048] Put 100g (0.5mol) of 4,4'-diaminodiphenyl ether, 54g (0.5mol) of p-phenylenediamine and 2200ml of dimethyl Acetamide, stir to dissolve completely, then add 310g (1mol) 2,3,3′,4′-diphenyl ether tetracarboxylic dianhydride, and react at room temperature for 4 hours to obtain a polyamic acid solution, and then proceed with the implementation Example 1 is the same. The yield of the molding powder was 88.3%, the logarithmic viscosity was 61.5ml / g, the glass transition temperature (Tg) was 303°C, and the weight loss temperatures of 5% and 10% were 551°C and 577°C, respectively (see Table 2).

[0049] Table-2: The mechanical properties of the copolyimide obtained in embodiment 2

[0050]

[0051] Bending strength, MPa

Embodiment 3

[0053] Put 130g (0.65mol) of 4,4′-diaminodiphenyl ether, 37.8g (0.35mol) of p-phenylenediamine and 2200ml of diphenylenediamine into a 5000ml four-neck round bottom flask equipped with a mechanical stirrer, a thermometer, and a nitrogen inlet and outlet. Methyl acetamide, stir and dissolve completely, then add 310g (1mol) 2,3,3′,4′-diphenyl ether tetracarboxylic dianhydride, react at room temperature for 4 hours to obtain a polyamic acid solution, and then proceed with Example 1 is the same. The yield of the molding powder was 88.6%, the logarithmic viscosity was 67.5ml / g, the glass transition temperature Tg was 294°C, and the weight loss temperatures of 5% and 10% were 541°C and 581°C, respectively (see Table- 3).

[0054] Table-3: Mechanical properties of the copolyimide obtained in Example 3

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com