Surface-mounted overvoltage and overcurrent protection device and manufacturing method thereof

An overvoltage and overcurrent protection, surface mount technology, used in overvoltage protection resistors, fuse manufacturing, emergency protection devices, etc., can solve the problems of small product capacitance, limited energy range, large printing area, etc. The effect of fast speed, improved reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

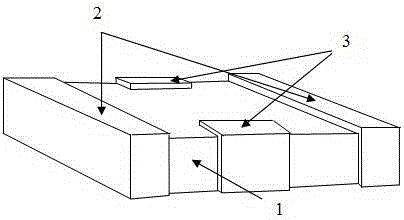

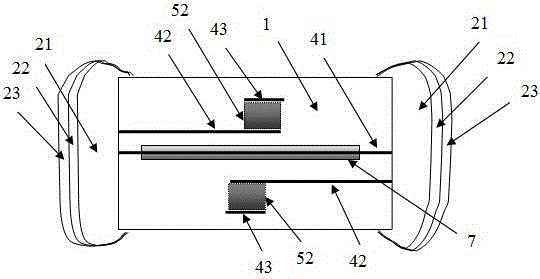

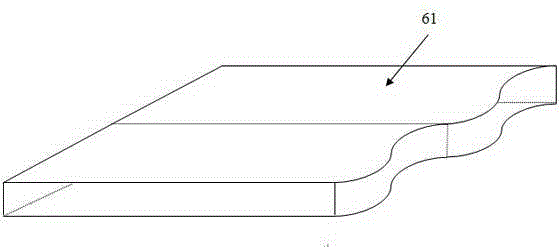

[0054] 1. Ingredients flow casting: select LTCC ceramic powder and pressure-sensitive ceramic material that meet the requirements to prepare slurry respectively. The sintering temperature of the two ceramic materials should be within the same temperature range, and their dielectric constant should be as small as possible. Generally, ceramic materials with a dielectric constant less than 10 are selected; LTCC ceramics can use common materials such as glass-ceramic systems or glass / ceramic composite systems, and mix them into qualified slurry through ball milling or sand milling, and then through casting process Obtain a certain width and thickness such as image 3 The shown LTCC ceramic diaphragm 61; the varistor functional phase 52 are mainly made of zinc oxide, tin oxide, strontium titanate and other materials with non-linear pressure-sensitive characteristics, mixed by ball milling, and the varistor ceramic powder, solvent, viscous Mixture and dispersant can be prepared into...

Embodiment 2

[0066] like Figure 11 As shown, according to the stacking sequence number described in step 8 in Example 1, the stacking method is changed to: a) stacking the lower protective layer 611 --> b) stacking the second electrode layer 43 --> c) stacking LTCC ceramics Diaphragm 5-->d) stacked first electrode layer 42-->e) stacked arc-extinguishing material coating 7-->f) stacked melt layer electrode pattern 41-->g) stacked arc-extinguishing material coating 7 -->f) Stacked melt layer electrode pattern 41 -->g) Stacked arc extinguishing material coating 7 -->h) Stacked first electrode layer 42 -->i) Stacked LTCC ceramic stacked diaphragm 5 --> j) stacking the second electrode layer 43 --> k) stacking the lower protective layer 612 to form a structure in which two layers of melt layer electrode patterns 41 are connected in parallel.

[0067] Others are made in the same manner as in Example 1.

Embodiment 3

[0069] like Figure 12 As shown, according to the stacking sequence number described in step 8 in Example 1, the stacking method is changed to: a) stacking the lower protective layer 611 --> d) stacking the first electrode layer 42 --> c) stacking LTCC ceramics Diaphragm 5-->b) stacked second electrode layer 43-->c) stacked LTCC ceramic stacked diaphragm 5-->d) stacked first electrode layer 42-->e) stacked arc-extinguishing material coating 7- ->f) Stacked melt layer electrode pattern 41-->g) Stacked arc-extinguishing material coating 7-->h) Stacked first electrode layer 42-->i) Stacked LTCC ceramic stacked diaphragm 5-->j ) stacking the second electrode layer 43 --> i) stacking the LTCC ceramic stack diaphragm --> h) stacking the first electrode layer 42 --> k) stacking the lower protective layer 612 to form an overvoltage and overcurrent protection device .

[0070] Others are made in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com