Multi-cell ranolazine slow-release pellet tablet

A technology of sustained-release pellets and sustained-release pellets, which is applied in the fields of pill delivery, medical preparations of non-active ingredients, cardiovascular system diseases, etc., and can solve problems such as pellet rupture, adhesion, and impact on formability, and achieve High bioavailability, large distribution area, good clinical significance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

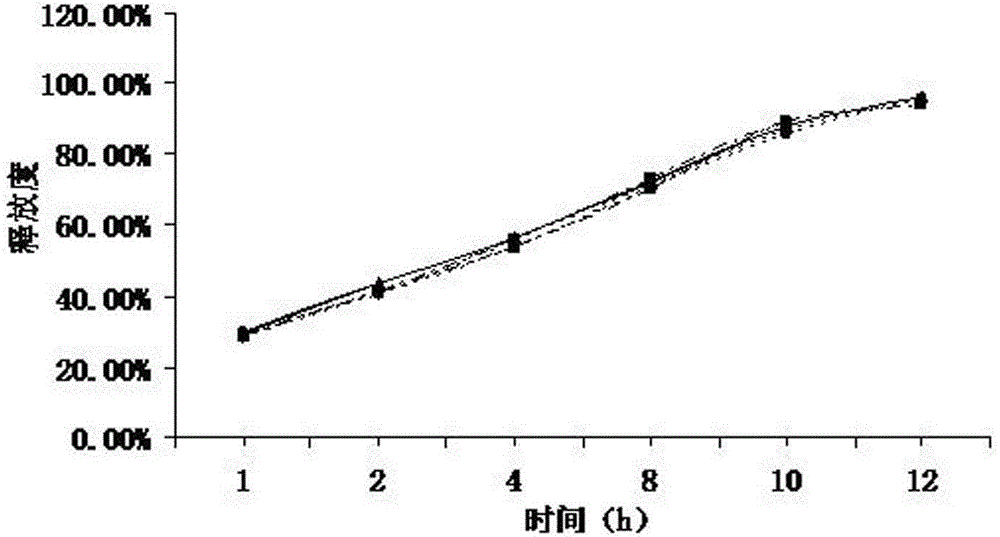

[0040]Weigh 60g of ranolazine, 25g of microcrystalline cellulose, 7g of lactose, 7g of precrossified starch, 1g of sodium lauryl sulfate, pass through a 100-mesh sieve and mix evenly, and use a 10% aqueous solution of povidone K30 as a binder to prepare Soft material, extruded and spheronized to prepare ranolazine drug-containing pellets, wherein the extrusion screen has an aperture of 0.6 mm, an extrusion speed of 25 r / min, dried at 40°C in a fluidized bed for 1 hour, and sieved to 20-40 mesh for use.

[0041] Put the screened ranolazine pellets in a fluidized bed, prepare a coating solution, adjust the fan frequency to 25HZ, the air inlet temperature to 30°C, the material temperature to 25°C and the flow rate of the coating solution to 0.4rpm, and control the coating weight gain to 5%. Ranolazine sustained-release pellets were prepared.

[0042] Coating solution ratio:

[0043] Sustained release material Acrylic resin 15%

[0044] Plasticizer Diethyl phthalate 3%

[0045]...

Embodiment 2

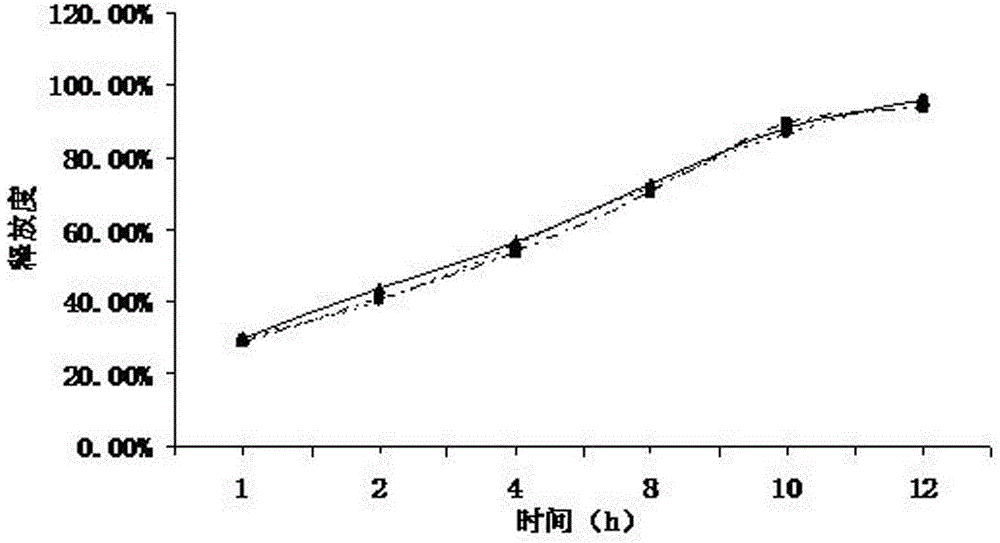

[0049] Weigh 80g of ranolazine, 15g of microcrystalline cellulose, 2g of lactose, 2g of starch, 0.8g of sodium lauryl sulfate, pass through a 100-mesh sieve and mix evenly, use 5% hypromellose E50M aqueous solution as a binder to make soft material, extruded and spheronized to prepare ranolazine drug-containing pellets, wherein the extrusion screen has an aperture of 0.8 mm, an extrusion speed of 25 r / min, dried at 40° C. in a fluidized bed for 1 hour, and sieved to 20-40 meshes for use.

[0050] The screened ranolazine pellets are placed in a fluidized bed to prepare a coating solution. Adjust the fan frequency to 25HZ, the air inlet temperature to 30°C, the material temperature to 25°C, and the flow rate of the coating solution to 0.4rpm, and control the coating weight gain to 5%, to prepare ranolazine sustained-release pellets.

[0051] Coating solution ratio:

[0052] Sustained release material Hypromellose 40%

[0053] Plasticizer triethyl citrate 5%

[0054] Anti-stic...

Embodiment 3

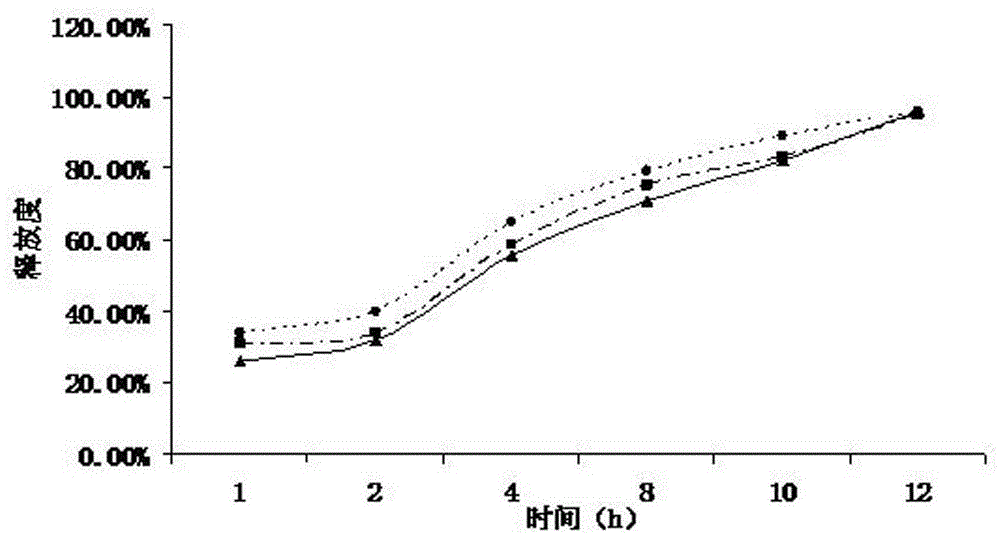

[0059] Weigh 95g of ranolazine, 3g of microcrystalline cellulose, 1g of lactose, and 1g of sodium lauryl sulfate, pass through a 100-mesh sieve and mix evenly, use 5% hypromellose K100M aqueous solution as a binder to make a soft material, and extrude Prepare ranolazine drug-containing pellets by spheronizing, wherein the extrusion screen has an aperture of 0.6mm, an extrusion speed of 25r / min, and is dried in a fluidized bed at 40°C for 1 hour, and sieved to 20-40 mesh for use.

[0060] The screened ranolazine pellets are placed in a fluidized bed to prepare a coating solution. Adjust the fan frequency to 25HZ, the air inlet temperature to 30°C, the material temperature to 25°C, and the flow rate of the coating solution to 0.4rpm, and control the coating weight gain to 5%, to prepare ranolazine sustained-release pellets.

[0061] Coating solution ratio:

[0062] Sustained release material Polyethylene glycol 5%

[0063] Plasticizers Diethyl phthalate, Dimethyl phthalate 6% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com