Preparation method and application of antibacterial repair type electrostatic spinning collagen-bacterial cellulose composite nanofiber scaffold

A technology of composite nanofibers and bacterial cellulose, applied in cellulose/protein conjugated rayon, fiber treatment, rayon manufacturing, etc., to achieve the effect of promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

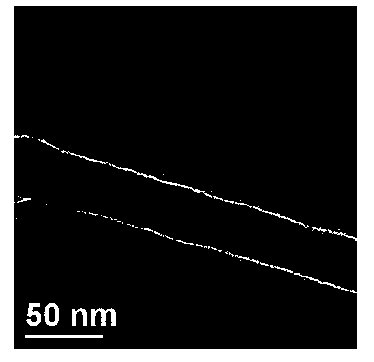

Image

Examples

Embodiment 1

[0030] (1) Preparation of mixed solvent: first prepare the ionic liquid 1-allyl-3-methylimidazole chloride (AMIMCL), add methylimidazole and allyl chloride with a volume ratio of 1:1.1 into a two-necked flask, Protect under nitrogen for five minutes, then heat and reflux at a constant temperature in an oil bath for a certain period of time; extract the reactant several times with anhydrous ether, then add activated carbon and deionized water, and conduct the reaction again at a certain temperature in the oil bath After reflux for several hours, a pale yellow liquid was obtained through diatomaceous earth, which was evaporated in vacuo, and then dried in vacuo for 48 hours to obtain AMIMCL; then 4-methylmorpholine-N-oxide (NMMO) and the obtained (AMIMCL) is mixed according to the mass ratio of 1:10, and the mass fraction of NMMO in the mixed system is 9% respectively;

[0031] (2) Preparation of bacterial cellulose solution: Dissolve 0.05g of bacterial cellulose in 10ml...

Embodiment 2

[0039] (1) Preparation of mixed solvent: first prepare ionic liquid 1-allyl-3-methylimidazole chloride (AMIMCL), add methylimidazole and allyl chloride with a volume ratio of 1:1.2 into a two-necked flask, Protect under nitrogen for five minutes, then heat and reflux at a constant temperature in an oil bath for a certain period of time; extract the reactant several times with anhydrous ether, then add activated carbon and deionized water, and conduct the reaction again at a certain temperature in the oil bath After reflux for several hours, a pale yellow liquid was obtained through diatomaceous earth, which was evaporated in vacuo, and then dried in vacuo for 48 hours to obtain AMIMCL; then 4-methylmorpholine-N-oxide (NMMO) and the obtained (AMIMCL) is mixed according to the mass ratio of 3:7, and the mass fraction of NMMO in the mixed system is 30% respectively;

[0040] (2) Preparation of bacterial cellulose solution: Dissolve 1g of bacterial cellulose in the above 10ml ...

Embodiment 3

[0048] (1) Preparation of mixed solvent: first prepare ionic liquid 1-allyl-3-methylimidazole chloride (AMIMCL), add methylimidazole and allyl chloride with a volume ratio of 1:1.6 into a two-necked flask, Protect under nitrogen for five minutes, then heat and reflux at a constant temperature in an oil bath for a certain period of time; extract the reactant several times with anhydrous ether, then add activated carbon and deionized water, and conduct the reaction again at a certain temperature in the oil bath After reflux for several hours, a pale yellow liquid was obtained through diatomaceous earth, which was evaporated in vacuo, and then dried in vacuo for 48 hours to obtain AMIMCL; then 4-methylmorpholine-N-oxide (NMMO) and the obtained (AMIMCL) is mixed according to the mass ratio of 7:3, and the mass fraction of NMMO in the mixed system is 70% respectively;

[0049] (2) Preparation of bacterial cellulose solution: Dissolve 1g of bacterial cellulose in 10ml of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com