High-conductivity polythiophene conductive coating layer and preparation method and application thereof

A high-conductivity, conductive coating technology applied in the field of materials to improve electrical and mechanical properties, reduce production costs, and facilitate processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

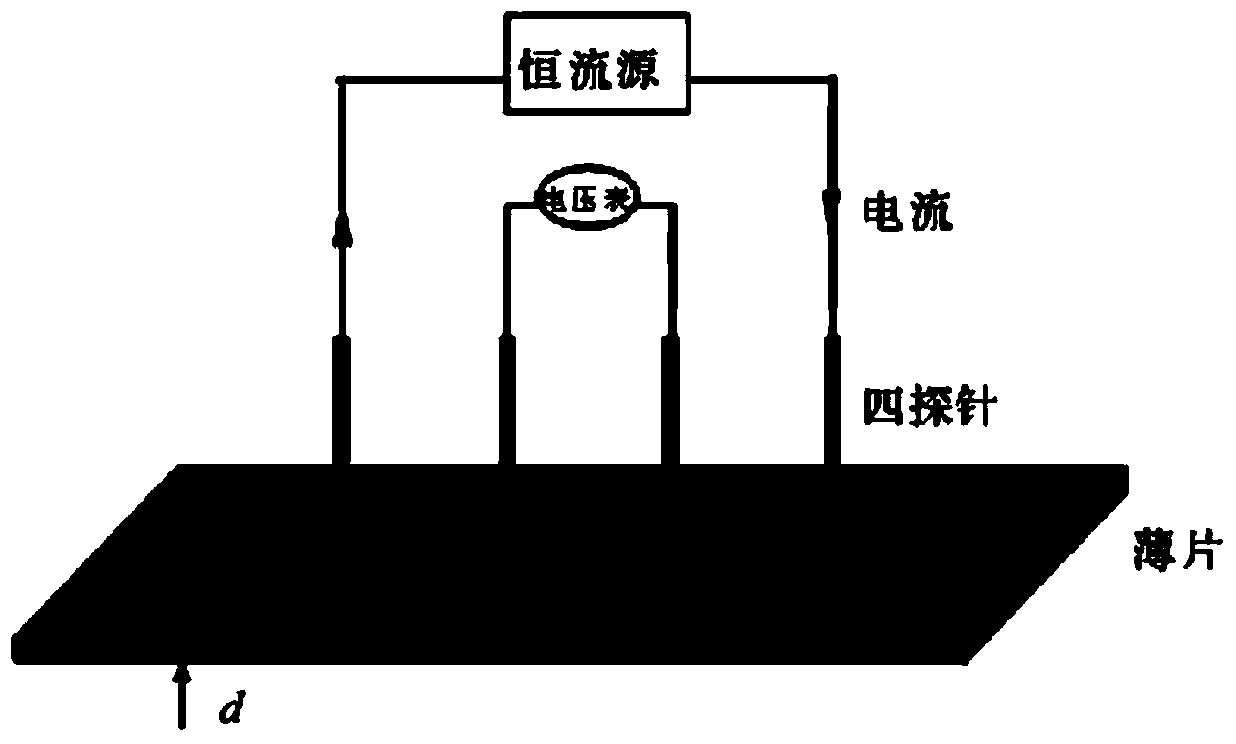

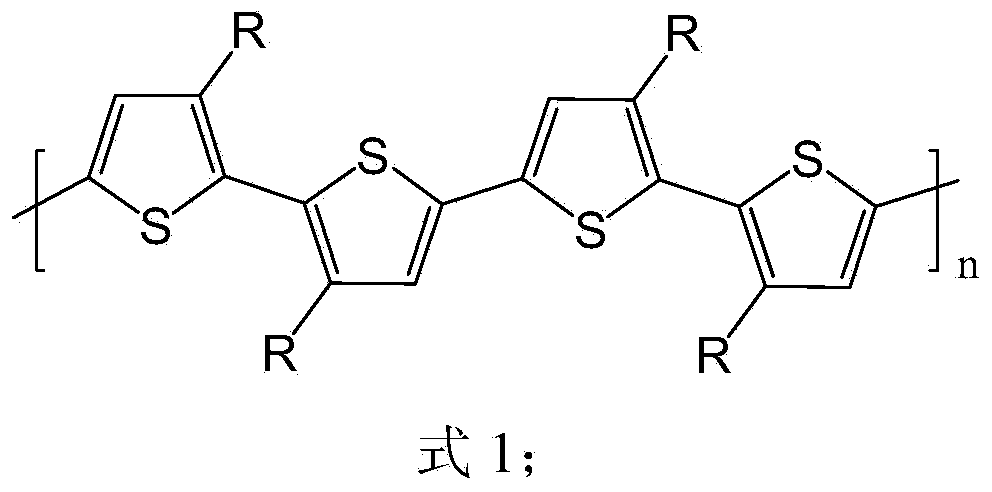

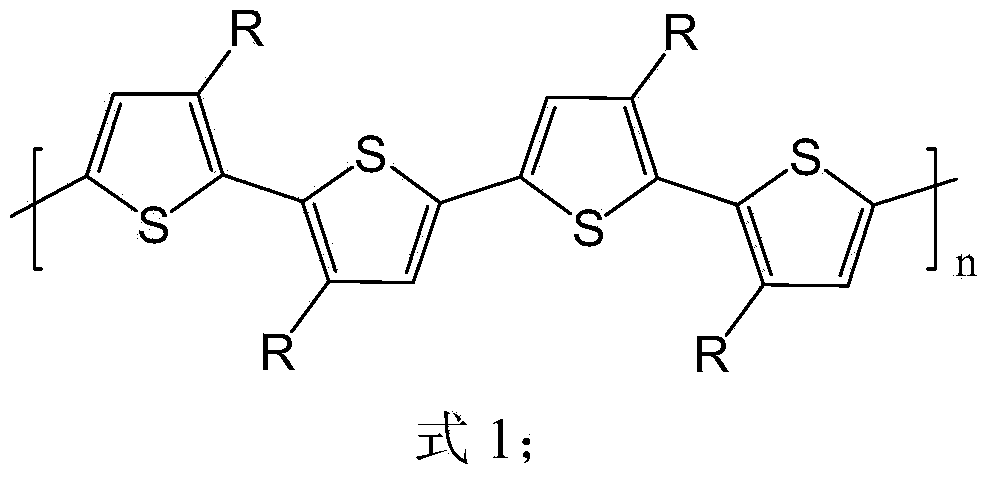

Method used

Image

Examples

Embodiment 1

[0038] (1) Sulfonating the polyethylene terephthalate film in chlorosulfonic acid at 0°C for a reaction time of 4 hours to obtain the sulfonated polyethylene terephthalate film; Rinse the sulfonated polyethylene terephthalate film three times with distilled water and then dry it at room temperature to obtain polyethylene terephthalate with sulfonate groups on the surface;

[0039](2) Put iron oxide and p-toluenesulfonic acid in a molar ratio of 1:0.8 into the reaction flask, add distilled water until its solid content is 40%, and reflux at 110°C for 6 hours to obtain iron p-toluenesulfonate solution, which can be removed by filtration After the unreacted iron oxide is recovered by high-vacuum and reduced-pressure distillation, most of the aqueous solution is recovered, and then a small amount of ethanol is added to bring water to the outside, and finally evaporated to dryness to obtain iron (Ⅲ) p-toluenesulfonate as a solid;

[0040] Dissolve thiophene in a mixed solvent compo...

Embodiment 2

[0043] (1) Sulfonating the polyethylene terephthalate film in chlorosulfonic acid at 0°C for a reaction time of 4 hours to obtain the sulfonated polyethylene terephthalate film; Rinse the sulfonated polyethylene terephthalate film with distilled water for 4 times and then dry it at room temperature to obtain a polyethylene terephthalate film with sulfonate groups on the surface;

[0044] (2) Put iron oxide and p-toluenesulfonic acid in a molar ratio of 1:0.8 into the reaction flask, add distilled water until its solid content is 40%, and reflux at 110°C for 6 hours to obtain iron p-toluenesulfonate solution, which can be removed by filtration After the unreacted iron oxide is recovered by high-vacuum and reduced-pressure distillation, most of the aqueous solution is recovered, and then a small amount of ethanol is added to bring water to the outside, and finally evaporated to dryness to obtain iron (Ⅲ) p-toluenesulfonate as a solid;

[0045] Dissolve thiophene in a mixed solve...

Embodiment 3

[0048] (1) Sulfonate the polyethylene terephthalate film in chlorosulfonic acid at 5°C for 2 hours to obtain the sulfonated polyethylene terephthalate film; Rinse the sulfonated polyethylene terephthalate film with distilled water for 5 times and then dry it at room temperature to obtain polyethylene terephthalate with sulfonate groups on the surface;

[0049] (2) Put iron oxide and naphthalenesulfonic acid into the reaction flask at a molar ratio of 1:0.8, add distilled water until its solid content is 40%, reflux at 110°C for 6 hours, and obtain ferric naphthalenesulfonate solution, filter to remove unreacted After the ferric oxide is obtained, most of the aqueous solution is recovered by high-vacuum and reduced-pressure distillation, and then a small amount of ethanol is added to bring water to the outside, and finally evaporated to dryness to obtain iron (Ⅲ) naphthalenesulfonate solid;

[0050] Dissolve 3-methylthiophene in a mixed solvent composed of chloroform and ether ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com