Method for preparation of bismuth-containing nano-hollow ball by using porous bismuth oxide as template

A bismuth oxide and bismuth nanotechnology, applied in chemical instruments and methods, nanotechnology, vanadium compounds, etc., can solve the problems of uneven resistance and uneven wall thickness of hollow microspheres, and achieve large-scale production and avoid wall thickness. The effect of uneven thickness and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of embodiment 1 porous bismuth oxide template comprises the steps:

[0035] Add 1.05mmol of bismuth nitrate pentahydrate, 0.50g of polyvinylpyrrolidone (PVP) and 4mmol of urea to 75mL of ethylene glycol (EG) solvent, and place the resulting reaction solution in a stainless steel autoclave lined with polytetrafluoroethylene In this method, after reacting under hydrothermal conditions at 150 °C for 3 h, the residual solute, solvent and PVP were removed by centrifugal washing, and the product was dried at 60 °C for 24 h, and porous bismuth oxide (Bi2O3) nanomaterials were obtained after cooling, with an average diameter of 180 nm. .

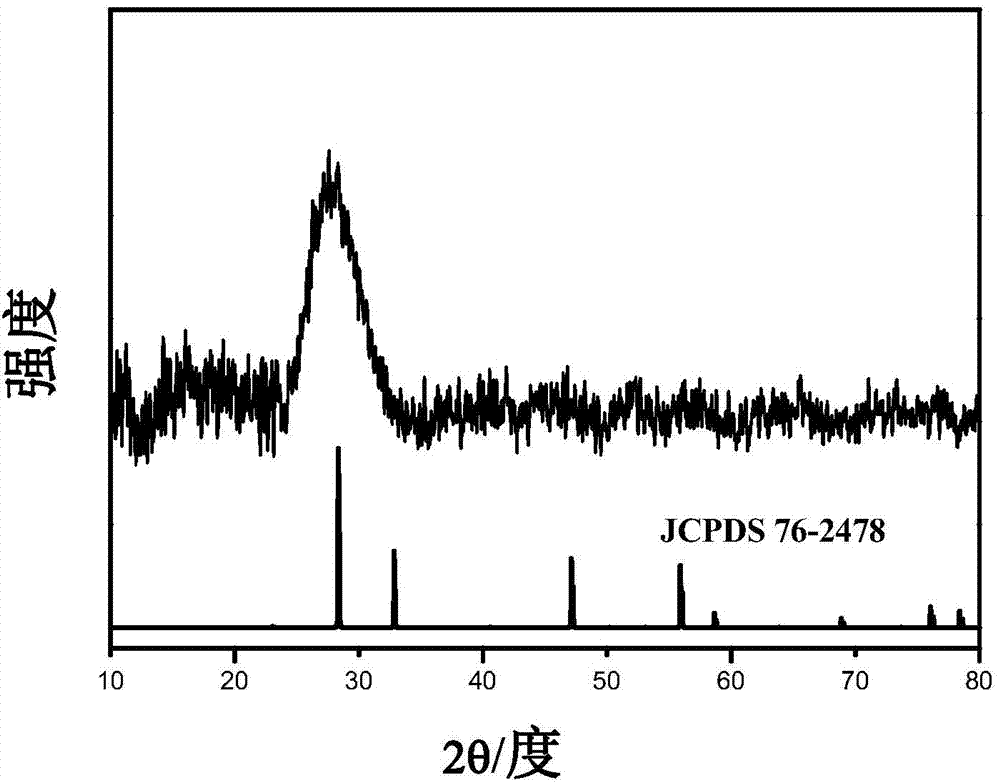

[0036] figure 1 It is the XRD spectrum of the porous bismuth oxide template obtained by Bruker axs D8 X-ray diffraction analyzer (XRD). It can be seen from the spectrum that the main peak of the spectrum is consistent with the bismuth oxide standard spectrum JCPDS76-2478, and no other impurity peaks appear, indicating...

Embodiment 2

[0038] The preparation method of embodiment 2 bismuth telluride hollow sphere nanomaterials comprises the following steps:

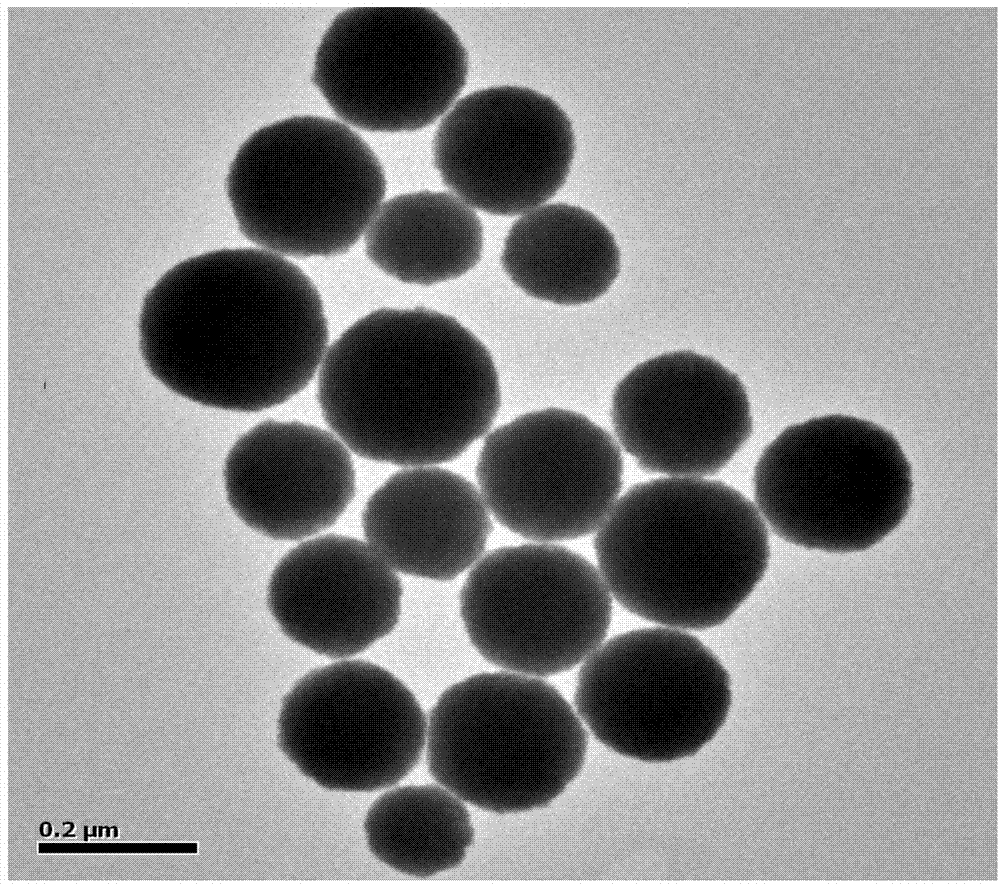

[0039]Take 0.05mmol of porous bismuth oxide obtained in Example 1, 0.15mmol of tellurium oxide and 2mmol of sodium borohydride in 5mL of deionized water; the reaction solution is placed in a stainless steel autoclave lined with polytetrafluoroethylene, at a temperature of 150 ° C Reacted for 12 hours; the obtained product was subjected to centrifugal washing to remove residual solutes. The centrifugal washing was to fully ultrasonically disperse the product with deionized water, and then centrifuged at 10,000rpm for 10 minutes to remove the supernatant, repeating 5 times, and then at 60 After drying at ℃ for 24 hours, bismuth telluride (Bi2Te3) hollow nanospheres can be obtained after cooling, with an average diameter of 196nm.

Embodiment 3

[0040] The preparation method of embodiment 3 bismuth telluride hollow sphere nanomaterials comprises the following steps:

[0041] Take 0.15mmol of porous bismuth oxide obtained in Example 1, 0.4mmol of tellurium oxide and 5.29mmol of sodium borohydride in 10mL of deionized water; the reaction solution is placed in a stainless steel autoclave lined with polytetrafluoroethylene, at a temperature of 150 ° C The reaction was carried out for 8 hours; the obtained product was subjected to centrifugal washing to remove residual solutes. The centrifugal washing was to fully ultrasonically disperse the product with deionized water, and then centrifuged at 10,000rpm for 10 minutes to remove the supernatant, repeated 5 times, and then in Dry at 60°C for 24 hours, and after cooling, bismuth telluride (Bi2Te3) hollow nanospheres can be obtained, with an average diameter of 201nm.

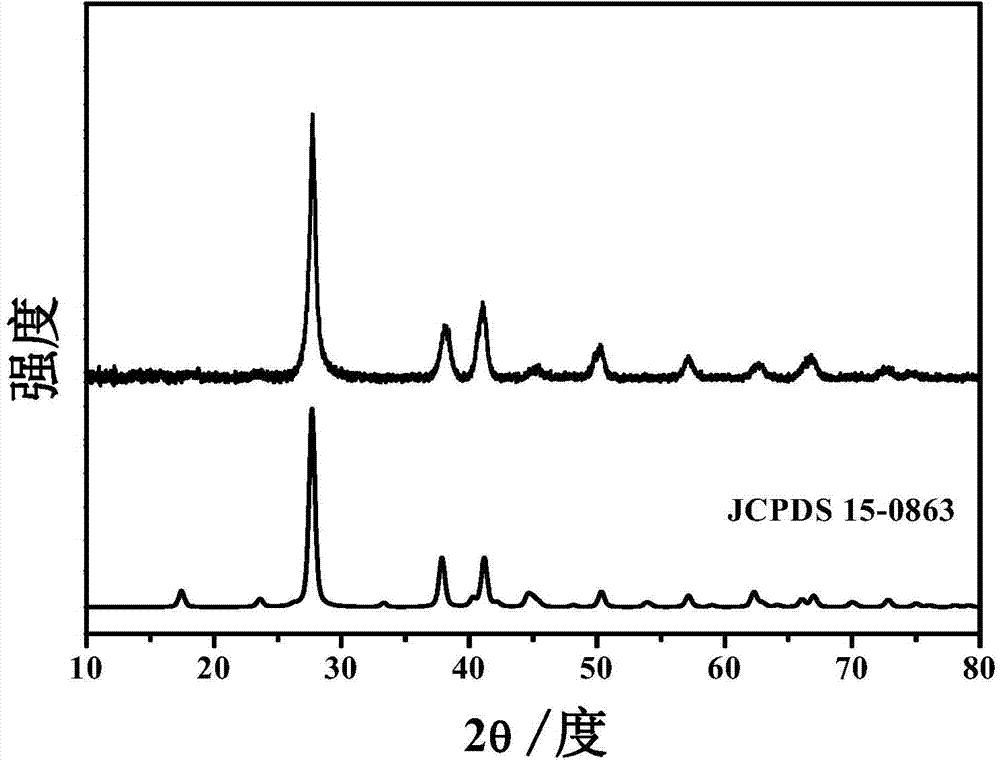

[0042] image 3 It is the XRD spectrum of the sample of Example 3 obtained by a Bruker axs D8 X-ray diffra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com