Method for preparing palygorskite clay based salt-tolerance super water absorbency composite material

A technology of palygorskite clay and composite materials, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve problems such as high cost, harsh synthesis conditions, and restrictions on the wide application and popularization of superabsorbent materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

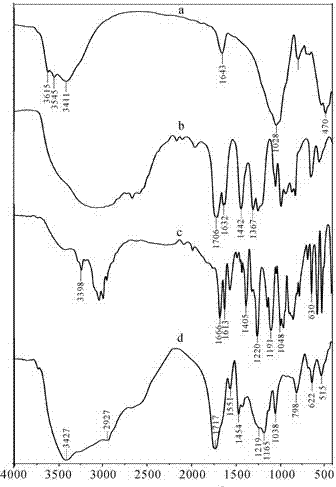

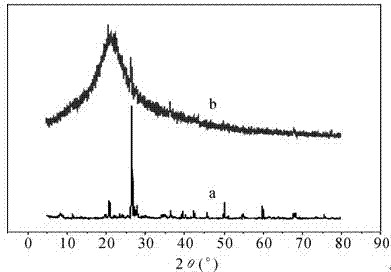

Method used

Image

Examples

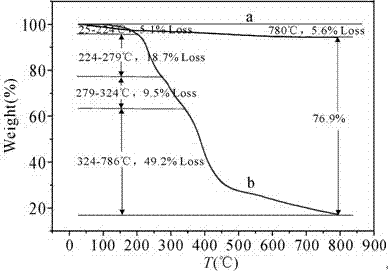

Embodiment 1

[0048] Add 0.6 g PGS and 30 mL distilled water into a 100 mL three-neck flask, stir at 80 °C for 1 h; then add 2 g AMP and 0.02 g MBA, continue stirring for 40 min; then add 8 mL AA, continue stirring at 75 °C After 1 h, a gel was formed, left for 3 h (post-polymerization time), and cooled to room temperature. Take out the product and cut it into fragments with a length of 2-5 mm with scissors. Wash several times with distilled water to remove unreacted monomers, small molecules and oligomers, then use ethanol to remove water from the material, and vacuum dry at 60°C to constant weight to obtain PGS / P (AMPS-co-AA) High water absorption material, crushed through a 100-mesh sieve for water absorption test. The yield was about 81%, and the grafting rate was 76.9%.

[0049] The performance indicators are as follows:

[0050] Water absorption performance: absorbing distilled water is basically saturated in 50 minutes, and the maximum amount of distilled water absorbed is 750 g / g...

Embodiment 2

[0052] Add 0.9 g PGS and 40 mL distilled water into a 100 mL three-neck flask, stir the mixture at 60 °C for 1 h, then add 2 g AMP and 0.05 g MBA, continue stirring for 60 min, then add 8 mL AA, continue to stir at 60 °C After stirring for 50 min, a gel was produced, which was left for 2.5 h (post-polymerization time), and then the product was cooled to room temperature. Take out the product and cut it into fragments with a length of 2-5 mm with scissors. Afterwards, the product was washed several times with distilled water to remove unreacted monomers, small molecules and oligomers, and the water in the material was removed with ethanol, and vacuum-dried at 50°C to constant weight to obtain PGS / P (AMPS-co -AA) Super absorbent material, crushed through a 100-mesh sieve for water absorption test. The yield was about 73%, and the grafting rate was 69%.

[0053] The performance indicators are as follows:

[0054] Water absorption performance: absorbing distilled water is basic...

Embodiment 3

[0056] Add 0.4 g PGS and 30 mL distilled water into a 100 mL three-neck flask, stir the mixture at 70 °C for 1 h, then add 2 g AMP and 0.07 g MBA, continue stirring for 40 min, then add 10 mL AA, continue to stir at 70 °C After stirring for 1 h, a gel was formed, which was placed at 70 °C for 2 h (post-polymerization time), and then the product was cooled to room temperature. Take out the product and cut it into fragments with a length of 2-5 mm with scissors. The product was washed several times with distilled water to remove unreacted monomers, small molecules and oligomers, the water in the material was removed with ethanol, and vacuum dried at 70°C to constant weight to obtain PGS / P (AMPS-co-AA) High water absorption material, crushed through a 100-mesh sieve for water absorption test. The yield was about 89%, and the grafting rate was 72%.

[0057] The performance indicators are as follows:

[0058] Water absorption performance: absorbing distilled water is basically s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com