Preparation method of a photosensitive nanocomposite supramolecular hydrogel

A technology of supramolecular hydrogel and nanocomposite, which is applied in the field of preparation of nanocomposite supramolecular hydrogel, can solve problems such as uneven distribution and damage to the stability of nanoparticles, and achieve good stability and good biocompatibility , Apply convenient and quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 10g polyethylene glycol monomethyl ether (average molecular weight 5,000) with 1.24g α - Lipoic acid was added to a reaction vessel containing 100mL of dry dichloromethane, under nitrogen protection, 0.24g of 4-dimethylaminopyridine and 0.20g of triethylamine were added, and then 1.24g of N,N'-dicyclohexane was added Carbodiimide, reacted at room temperature for 48 hours, precipitated with petroleum ether, after the product was dried, dissolved in 250mL of absolute ethanol with slight heat, cooled and precipitated, filtered, dissolved and precipitated three times, and the product was vacuumed at room temperature Dry to constant weight to obtain polyethylene glycol monomethyl ether lipoate.

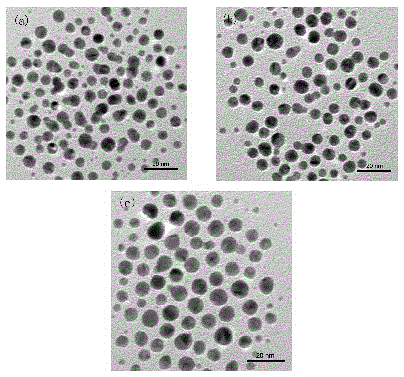

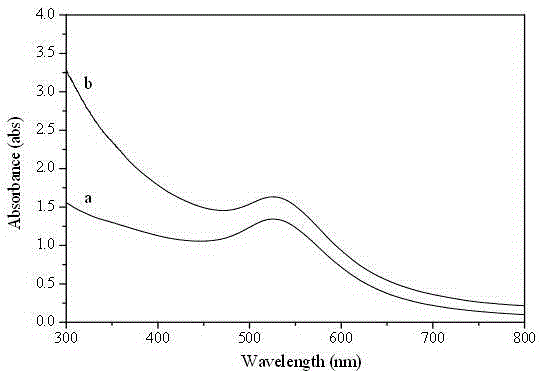

[0019] 0.3gHAuCl 4 4H 2 O and 3.78 g of the above-prepared polyethylene glycol monomethyl ether lipoate were dissolved in a reaction vessel containing 60 mL of dry tetrahydrofuran, and stirred at room temperature for 12 h under the protection of nitrogen in the dark. Then add...

Embodiment 2

[0022] Add 0.2 g of HAuCl to the reaction vessel containing 100 mL of dry THF 4 4H 2 O and 2.91 g of mercapto polyethylene glycol monomethyl ether (average molecular weight: 1,000), under the protection of nitrogen, stirred at room temperature in the dark for 12 h. Then add 14.6mL of 0.2mol / L NaBH with a syringe 4 The tetrahydrofuran solution was stirred and reacted at room temperature for 8 hours, precipitated with anhydrous ether, filtered, and then the precipitate was dissolved in distilled water and placed in a dialysis bag with a molecular weight cutoff of MWCO50kDa, dialyzed in a large amount of distilled water for 5 days, and finally freeze-dried. Au nanoparticles protected by self-assembled monolayer of polyethylene glycol monomethyl ether were obtained.

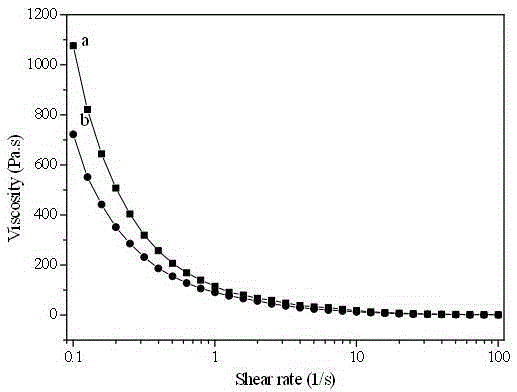

[0023] At room temperature, add 7.62g of 12% by mass to the aqueous solution of gold nanoparticles protected by the self-assembled monolayer of polyethylene glycol monomethyl ether prepared above with a concentrati...

Embodiment 3

[0025] Mix 10g polyethylene glycol monomethyl ether (average molecular weight 5,000) with 1.24g α - Lipoic acid was added to a reaction vessel containing 100mL of dry dichloromethane, under nitrogen protection, 0.24g of 4-dimethylaminopyridine and 0.20g of triethylamine were added, and then 1.24g of N,N'-dicyclohexane was added Carbodiimide, reacted at room temperature for 48 hours, precipitated with petroleum ether, after the product was dried, dissolved in 250mL of absolute ethanol with slight heat, cooled and precipitated, filtered, dissolved and precipitated repeatedly 4 times, and the product was vacuumed at room temperature Dry to constant weight to obtain polyethylene glycol monomethyl ether lipoate.

[0026] 0.25gHAuCl 4 and 7.56 g of the above-prepared polyethylene glycol monomethyl ether lipoate were dissolved in a reaction vessel containing 100 mL of dry tetrahydrofuran, and stirred at room temperature for 12 h under the protection of nitrogen in the dark. Then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com