CuO/Cu nanowire negative electrode material in core-shell structure and preparation method and application thereof

A technology of negative electrode material and core-shell structure, which is applied in the field of CuO/Cu nanowire negative electrode material and its preparation, can solve the problems of unfavorable electrode processing and assembly, difficulty in expanding production, and no formation of core-shell structure, etc., and achieve the best comprehensive performance And practicability, simple and controllable preparation method, and the effect of fast electron transfer channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

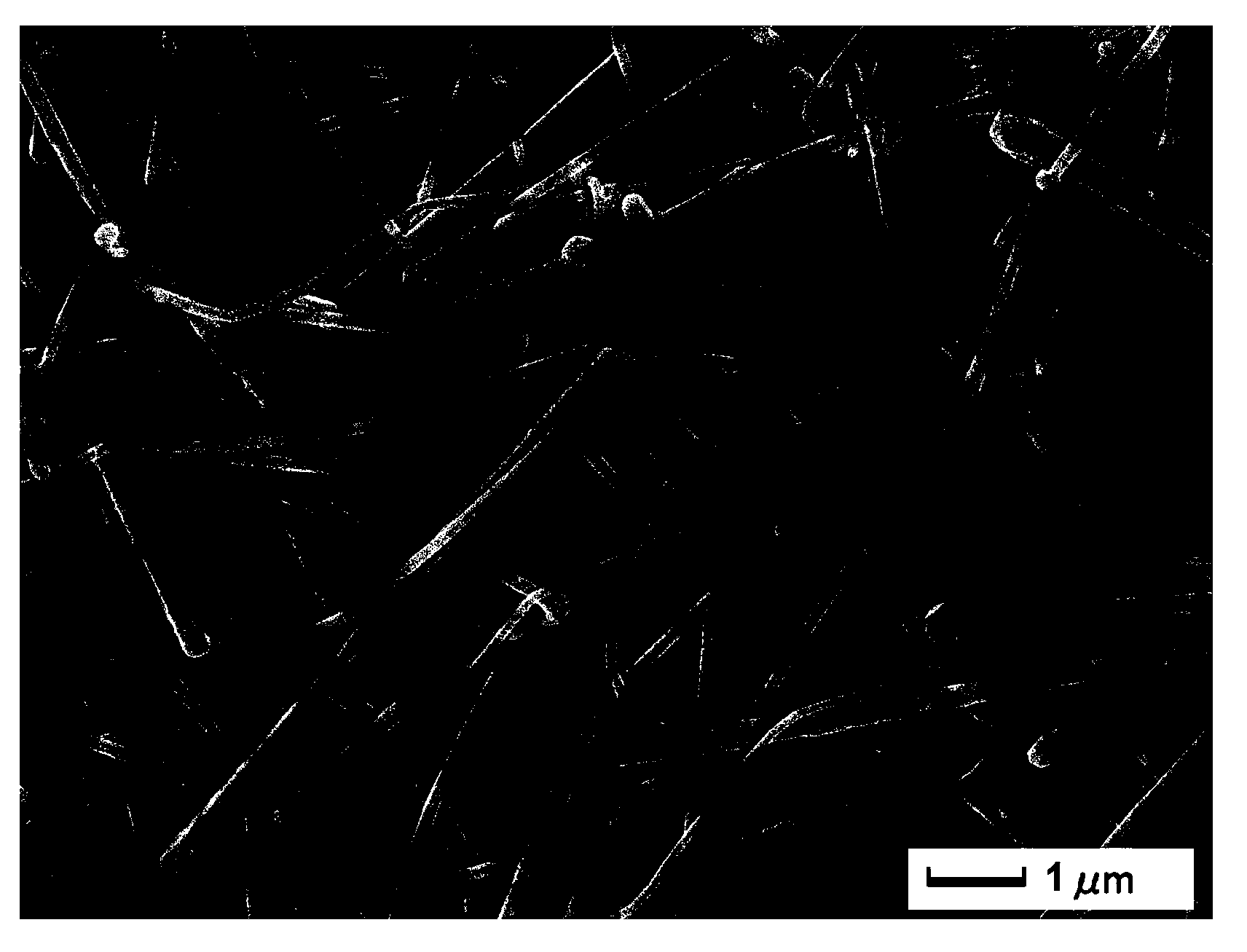

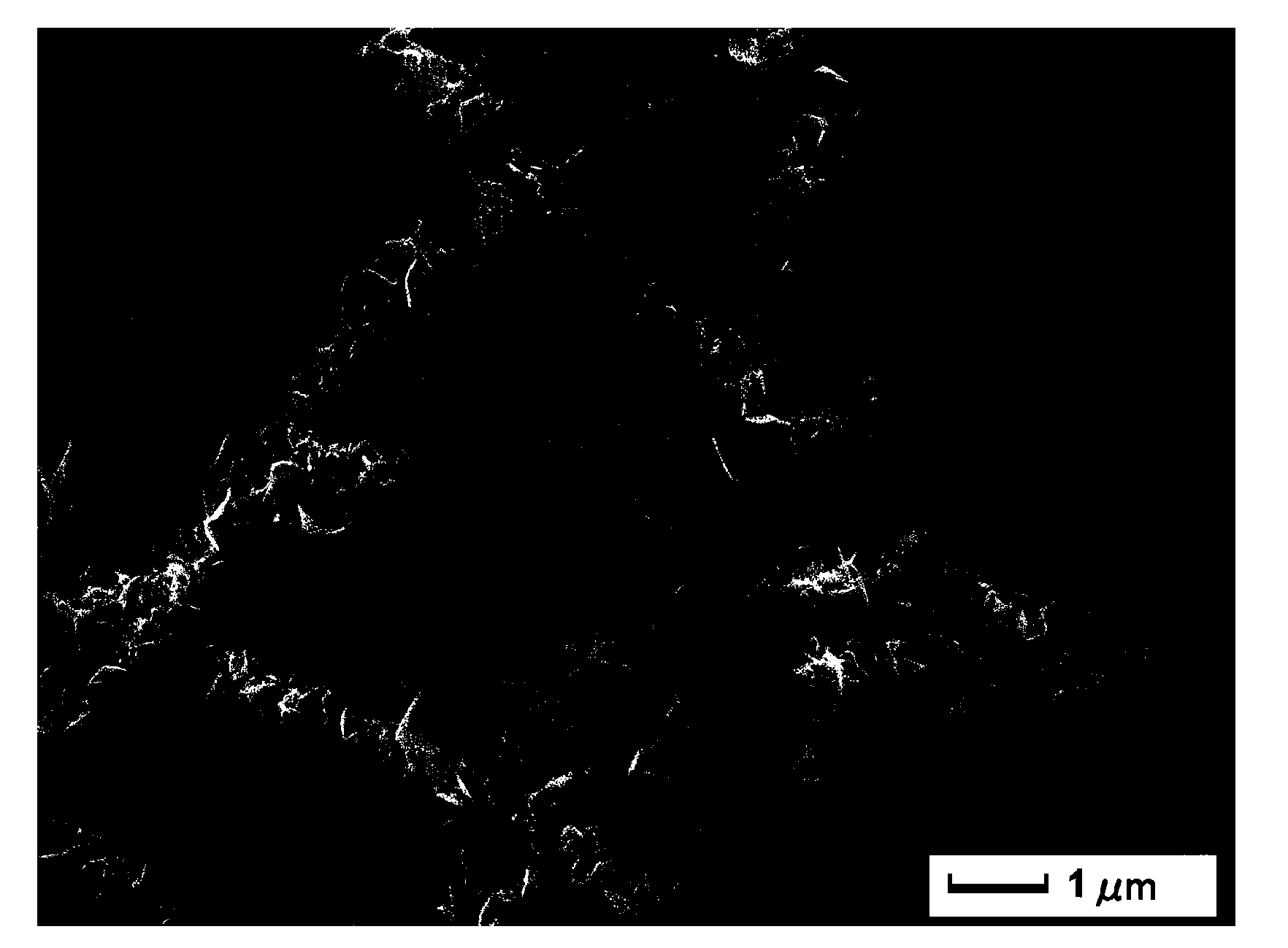

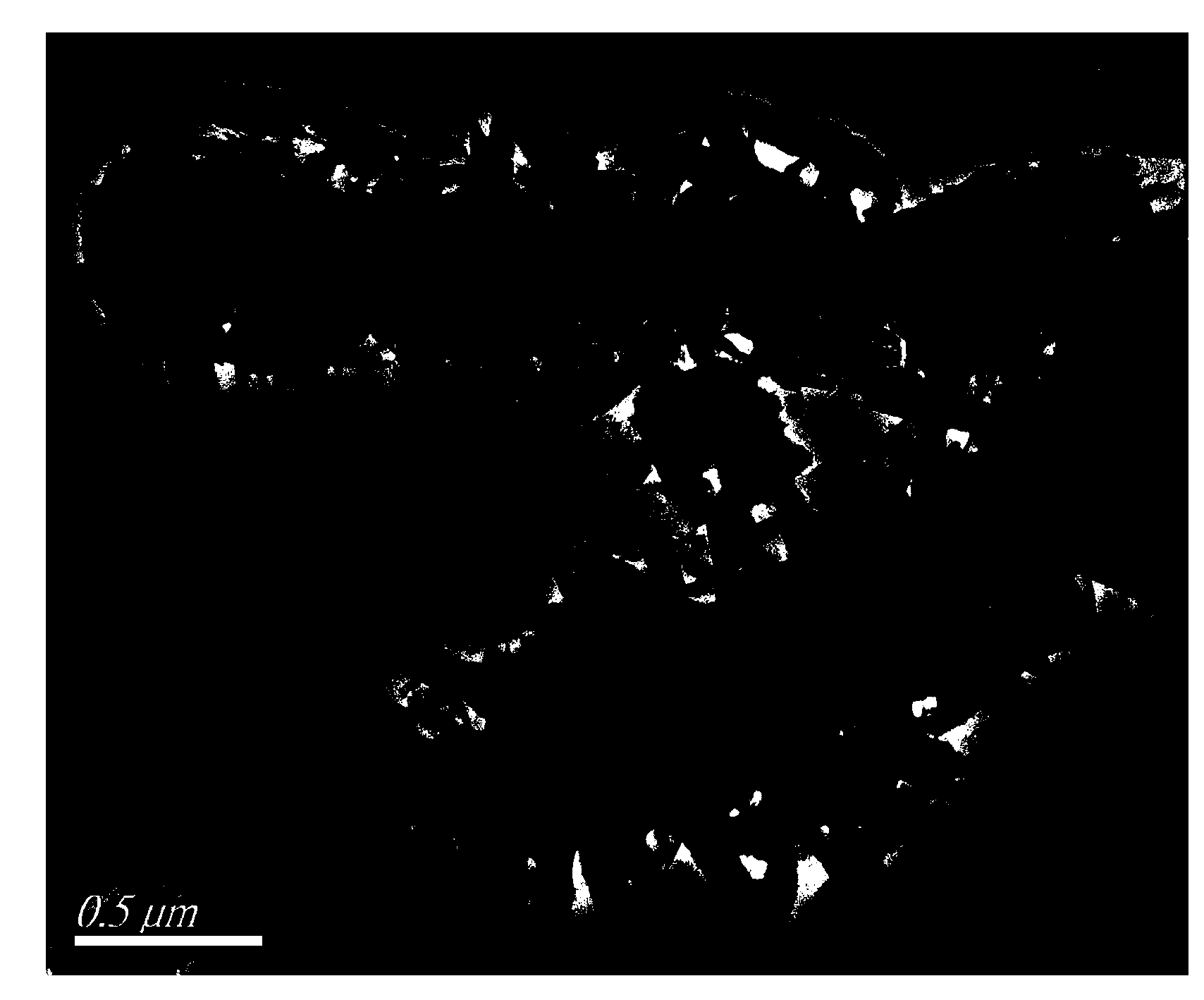

[0034]A core-shell structure CuO / Cu nanowire negative electrode material of the present invention, the nanowire negative electrode material is mainly composed of CuO and Cu, wherein the metal Cu is nanowire-shaped, CuO is flower-shaped, and the nanowire-shaped metal Cu is used as the core of the nanowire anode material, and the flower-shaped CuO is coated on the outer surface of the nanowire-shaped metallic Cu to form a core-shell structure. The metal Cu has a diameter of about 140 nm and a length of 30 μm to 50 μm, and the coating thickness of CuO on the outer surface of the metal Cu is about 300 nm. Flower-like CuO is coated on the outer surface of metallic Cu by in-situ growth.

[0035] The method for preparing the core-shell structure CuO / Cu nanowire negative electrode material of the above embodiment specifically includes the following steps:

[0036] (1) Prepare 0.1M copper acetate solution, 15M sodium hydroxide solution, anhydrous ethylenediamine solution with a mass f...

Embodiment 2

[0041] A core-shell structure CuO / Cu nanowire negative electrode material of the present invention, the nanowire negative electrode material is mainly composed of CuO and Cu, wherein the metal Cu is nanowire-shaped, CuO is flower-shaped, and the nanowire-shaped metal Cu is used as the core of the nanowire anode material, and the flower-shaped CuO is coated on the outer surface of the nanowire-shaped metallic Cu to form a core-shell structure. The metal Cu has a diameter of 60 nm and a length of 5 μm to 15 μm, and the coating thickness of CuO on the outer surface of the metal Cu is 100 nm. Flower-like CuO is coated on the outer surface of metallic Cu by in-situ growth.

[0042] The method for preparing the core-shell structure CuO / Cu nanowire negative electrode material of the above embodiment specifically includes the following steps:

[0043] (1) Prepare 0.5M copper acetate solution, 10M sodium hydroxide solution, anhydrous ethylenediamine solution with a mass fraction of mo...

Embodiment 3

[0048] A core-shell structure CuO / Cu nanowire negative electrode material of the present invention, the nanowire negative electrode material is mainly composed of CuO and Cu, wherein the metal Cu is nanowire-shaped, CuO is flower-shaped, and the nanowire-shaped metal Cu is used as the core of the nanowire anode material, and the flower-shaped CuO is coated on the outer surface of the nanowire-shaped metallic Cu to form a core-shell structure. The metal Cu has a diameter of 75 nm and a length of 70 μm to 100 μm, and the coating thickness of CuO on the outer surface of the metal Cu is about 210 nm. Flower-like CuO is coated on the outer surface of metallic Cu by in-situ growth.

[0049] The method for preparing the core-shell structure CuO / Cu nanowire negative electrode material of the above embodiment specifically includes the following steps:

[0050] (1) Prepare 0.25M copper acetate solution, 12M sodium hydroxide solution, anhydrous ethylenediamine solution with a mass fract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com