Method for preparing surface medicinal coating of gastric tube

A drug coating and gastric tube technology, applied in coatings, catheters, etc., can solve the problems of unsuitable for wide application, drug shedding, high cost, etc., and achieve good biodegradability, good biocompatibility, and no toxic side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Duhuo 5.82g, Raw Araceae 2.91g, Raw Aconitum 0.727g, Acacia 1.1g, Glauber's Salt 36.06g, Methyl Salicylate 2.385g, Borneol 0.096g, the above drugs are all powder, passed through a 100-mesh sieve, and added to 450g of ethanol Ultrasonic dispersion was uniform to obtain an electrostatic spray solution; 6 g of zein (Zein, molecular weight 22,000) was added to 14 g of glacial acetic acid, stirred and dissolved, and an electrospinning solution with a mass fraction of 30% was prepared.

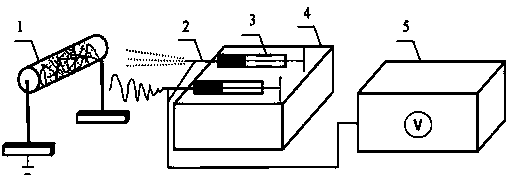

[0031] Pour the above-mentioned solutions into 20 mL capacity syringes respectively, and place in such figure 1 On the syringe pump, the propulsion speed of the electrostatic spray was set to 0.5 mL / min, the propulsion speed of the electrospinning was 1.0 mL / min, the horizontal distance between the side of the receiving roller close to the needle and the metal needle was 18 cm, and the stomach tube was set on On the receiving drum, a high voltage power supply provides a voltage of 20 kV. Aft...

Embodiment 2

[0034] Raw rhubarb 2g Glauber's salt 6g Frankincense 8g Myrrh 8g Raw Nuxychonnia 6g Borneol 10g, the above medicines are all powders, passed through a 100 mesh sieve, added to 360g ethanol and ultrasonically dispersed to obtain an electrostatic spray solution; 2g polylactic acid (PLA, molecular weight 70,000) into a mixed solution of 13.7 g of dichloromethane and 4.22 g of N, N-dimethylformamide, stirred and dissolved to prepare an electrospinning solution with a mass fraction of 10%.

[0035] Pour the above-mentioned solutions into 20 mL capacity syringes respectively, and place in such figure 1On the syringe pump, the propulsion speed of the electrostatic spray was set to 0.3 mL / min, the propulsion speed of the electrospinning was 1.0 mL / min, the horizontal distance between the side of the receiving roller close to the needle and the metal needle was 20 cm, and the gastric tube was set on On the receiving drum, a high voltage power supply provides a voltage of 18 kV. After ...

Embodiment 3

[0038] Naproxen, naproxen, rofecoxib, and celecoxib, each 2g, were dispersed in 400g ethanol by ultrasonic to prepare an electrostatic spray solution; 5.4g Zein (Zein, molecular weight: 22,000) 14.6 g of glacial acetic acid was stirred and dissolved to prepare an electrospinning solution with a mass fraction of 27%.

[0039] Pour the above-mentioned solutions into 20 mL capacity syringes respectively, and place in such figure 1 On the syringe pump, the propulsion speed of the electrostatic spray is set to 1 mL / min, the propulsion speed of the electrospinning is 1.5 mL / min, the horizontal distance between the side of the receiving roller close to the needle and the metal needle is 18 cm, and the gastric tube is set on On the receiving drum, a high voltage power supply provides a voltage of 20 kV. After the electrospinning solution is exhausted, the preparation process is stopped. After the solvent volatilizes, the surface drug-loaded composite gastric tube is obtained.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com