Preparation method of amylase

A technology of amylase and starch, applied in the direction of biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., to achieve high yield and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 A method for extracting amylase from barley malt

[0048] The method for extracting amylase from barley malt comprises the following steps:

[0049] (1) Crushed barley malt

[0050] The barley malt is placed in a pulverizer to pulverize, and the pulverized product is passed through an 80-mesh sieve, and the undersize is collected. Weighing, ration packaging, and marking the name, weight, batch number and other content for future use.

[0051] (2) Leaching

[0052] (1) Extraction preparation: Add 0.25kg of sodium metabisulfite, 0.25kg of sodium pyrosulfite, 0.25kg of sodium sulfite, 0.25kg of sodium thiosulfate and 0.05kg of potassium sorbate to 100L of purified water, mix well and set aside.

[0053] (2) Amylase extraction: Weigh 10kg of barley malt crushed material into the extraction solution prepared in step (1), add 0-5g of cellulose compound enzyme, mix well, heat and control the temperature under normal pressure at 20-45°C, adjust the pH value to 5, ...

Embodiment 2

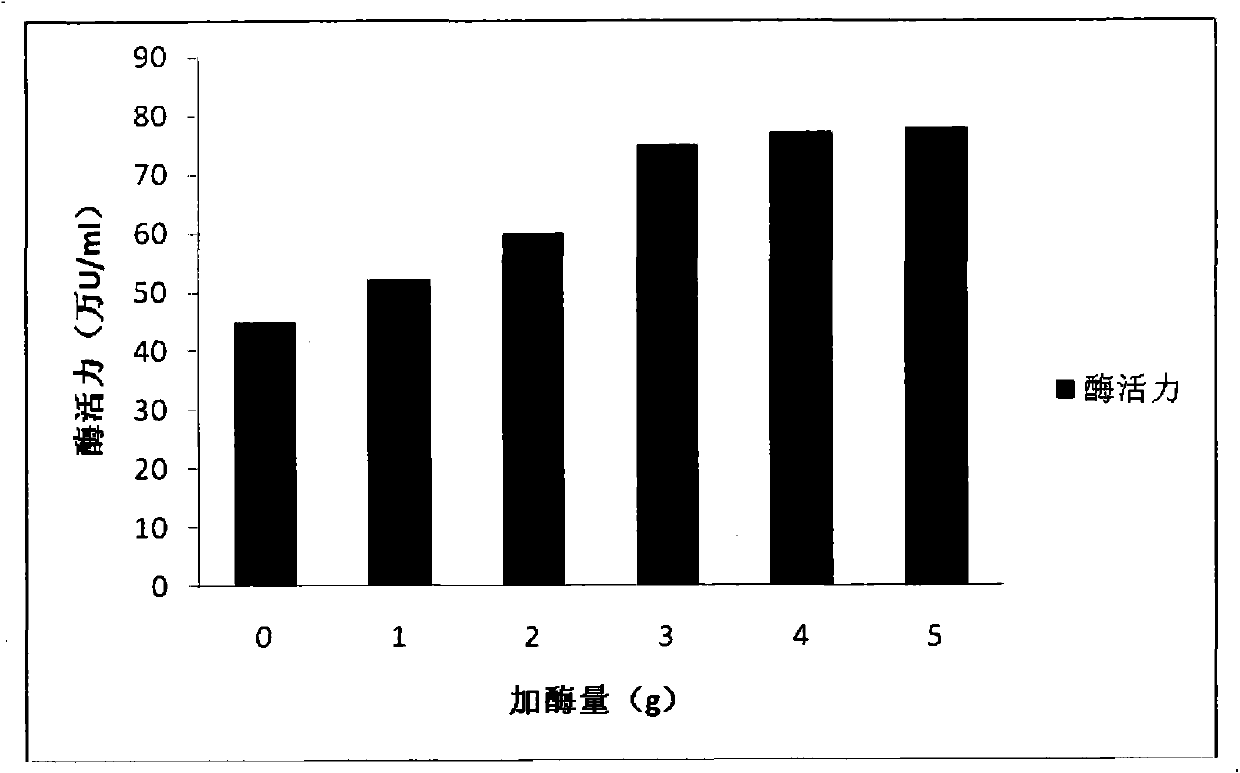

[0071] Example 2 Effect of the amount of cellulose compound enzyme on the activity of amylase in the concentrated enzyme solution

[0072] Steps:

[0073] (1) The crushing of barley malt is the same as in Example 1.

[0074] (2) Leaching

[0075] (1) Extraction preparation: Add 0.25kg of sodium metabisulfite, 0.25kg of sodium metabisulfite, 0.25kg of sodium bisulfite, 0.25kg of sodium thiosulfate and 0.05kg of potassium sorbate to 100L of purified water, mix well and set aside.

[0076] (2) Amylase extraction: Weigh 10 kg of barley malt pulverization and add it to the extract prepared in step (1), add 0, 1, 2, 3, 4, 5 g of cellulose compound enzyme (β-glucan Enzyme activity not less than 8000U / g, cellulase activity not less than 200U / g, neutral protease activity not less than 500U / g, xylanase activity not less than 3000U / g), divided into six groups for testing. After fully mixing, under normal pressure, heat and control the temperature to 30°C, adjust the pH value to 5, and...

Embodiment 3

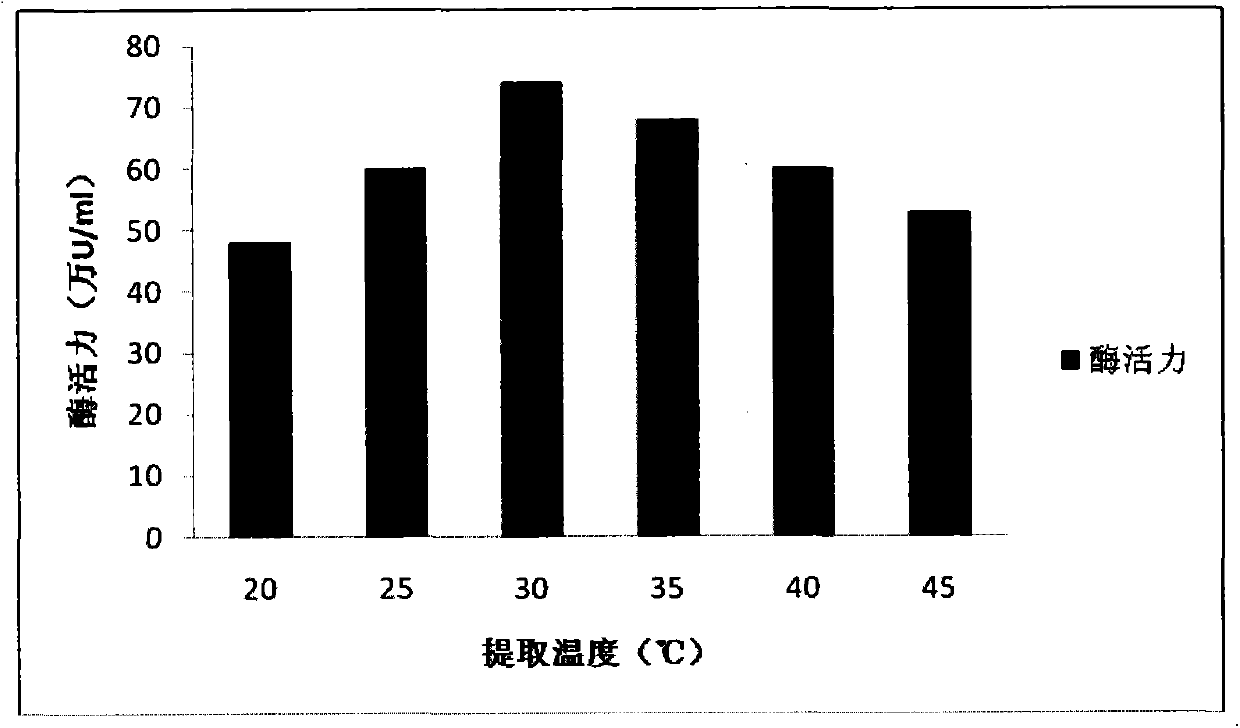

[0121] Example 3 Effect of Extraction Temperature on Amylase Activity in Concentrated Enzyme Liquid

[0122] Steps:

[0123] (1) The crushing of barley malt is the same as in Example 1.

[0124] (2) Leaching

[0125] (1) Extraction preparation: Add 0.25kg of sodium metabisulfite, 0.25kg of sodium metabisulfite, 0.25kg of sodium bisulfite, 0.25kg of sodium thiosulfate and 0.05kg of potassium sorbate to 100L of purified water, mix well and set aside.

[0126] (2) Amylase extraction: Weigh 10kg of barley malt ground into the extract prepared in step (1), add 3g of cellulose complex enzyme (β-glucanase activity is not less than 8000U / g, cellulase Activity of not less than 200U / g, activity of neutral protease not less than 500U / g, activity of xylanase not less than 3000U / g), after mixing thoroughly, heat and control the temperature at 20°C under normal pressure , 25°C, 30°C, 35°C, 40°C, 45°C, divided into six groups for testing. Adjust the pH value to 5, and extract with stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com