Citric acid extraction method and membrane bioreactor for producing citric acid

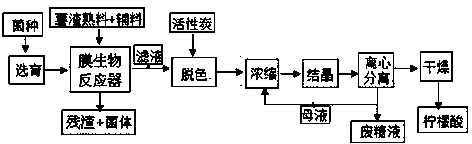

The technology of membrane bioreactor and extraction method is applied in the field of membrane bioreactor and citric acid extraction process, which can solve the problems of serious environmental pollution, poor citric acid selectivity and high production cost, and achieves improved fermentation depth and high citric acid production. The effect of improving the fermentation rate and fermentation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

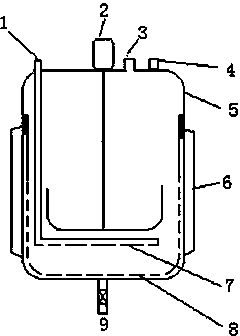

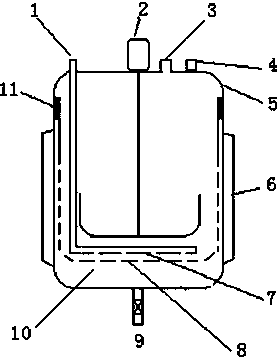

[0045] A method for producing citric acid, a membrane bioreactor for producing citric acid and a citric acid extraction process. The membrane bioreactor is lined with a polysulfone ultrafiltration membrane with good oxidation resistance and acid resistance. The effective volume is 100L. The device integrates fermentation and membrane separation. The fermentation process and the membrane separation process are carried out alternately. Three fermentations were separated from the membrane to prepare and extract citric acid. Put the selected strains into the sterilized potato dregs clinker (dried potato dregs 40kg) and a suitable proportion of nitrogen source rice bran and calcium carbonate auxiliary materials, and the first fermentation reaches a fermentation depth of 60-70%. The second round of fermentation can reach a fermentation depth of about 80-85%, and the third round of fermentation can reach a fermentation depth of about 90-95%.

[0046] The polysulfone ultrafiltration ...

Embodiment 2

[0058] A method for producing citric acid, a membrane bioreactor for producing citric acid and a citric acid extraction process. The membrane bioreactor is lined with a polysulfone ultrafiltration membrane with good oxidation resistance and acid resistance. The effective volume is 100L. The device integrates fermentation and membrane separation. The fermentation process and the membrane separation process are carried out alternately. Three times of fermentation and membrane separation, preparation and separation of citric acid; put the selected strains into the sterilized potato dregs clinker (dried potato dregs 40kg) and 0.7% nitrogen source ammonium sulfate and 2% calcium carbonate Among the auxiliary materials, the first fermentation can reach a fermentation depth of 70%, the second round of fermentation can reach a fermentation depth of 85%, and the third round of fermentation can reach a fermentation depth of 95%. The implementation steps are the same as in Embodiment 1. ...

Embodiment 3

[0060] A method for producing citric acid, a membrane bioreactor for producing citric acid and a citric acid extraction process, the membrane bioreactor is a polysulfone ultrafiltration membrane with a liner with good oxidation resistance and acid resistance, and the effective volume is 100L, the device integrates fermentation and membrane separation, the fermentation process and the membrane separation process are carried out alternately, after three times of fermentation and membrane separation, citric acid is prepared and separated; the selected strains are put into the sterilized potato dregs In clinker (dried potato residue 40kg) and 0.4% nitrogen source urea and 2% calcium carbonate auxiliary materials, the first fermentation reaches a fermentation depth of 67%, the second round of fermentation can reach a fermentation depth of about 82%, and the third round of fermentation can reach a fermentation depth of about 82%. Round fermentation can reach about 95% fermentation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com