Method for preparing quantitative standard substance of photosynthetic pigments

A quantitative standard product, photosynthetic pigment technology, applied in the field of quantitative standard product preparation of phytoplankton photosynthetic pigment, can solve the problems of high price, low concentration, incomplete variety, etc., achieve high accuracy and reliability, single component, low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

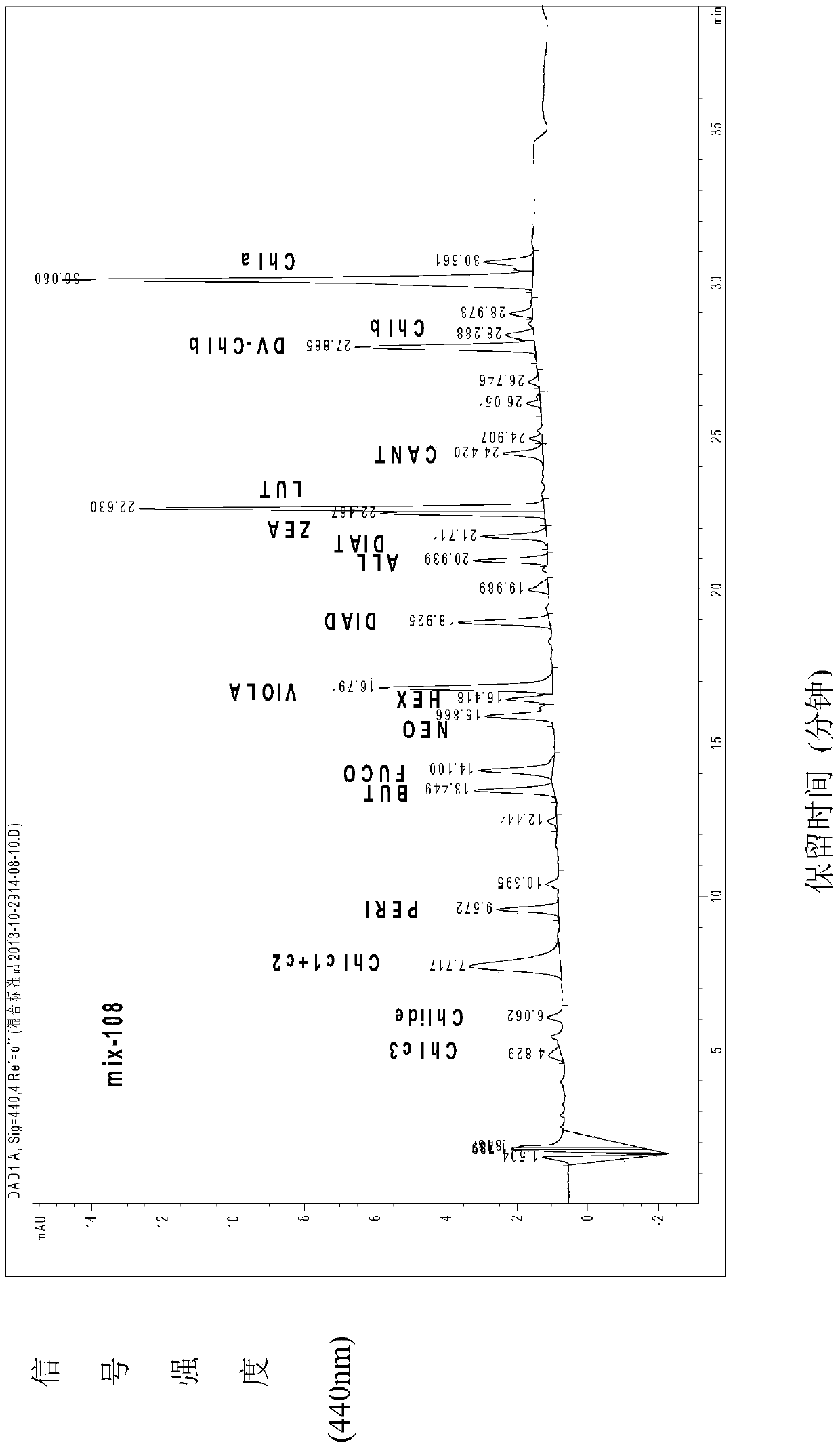

Method used

Image

Examples

Embodiment 1

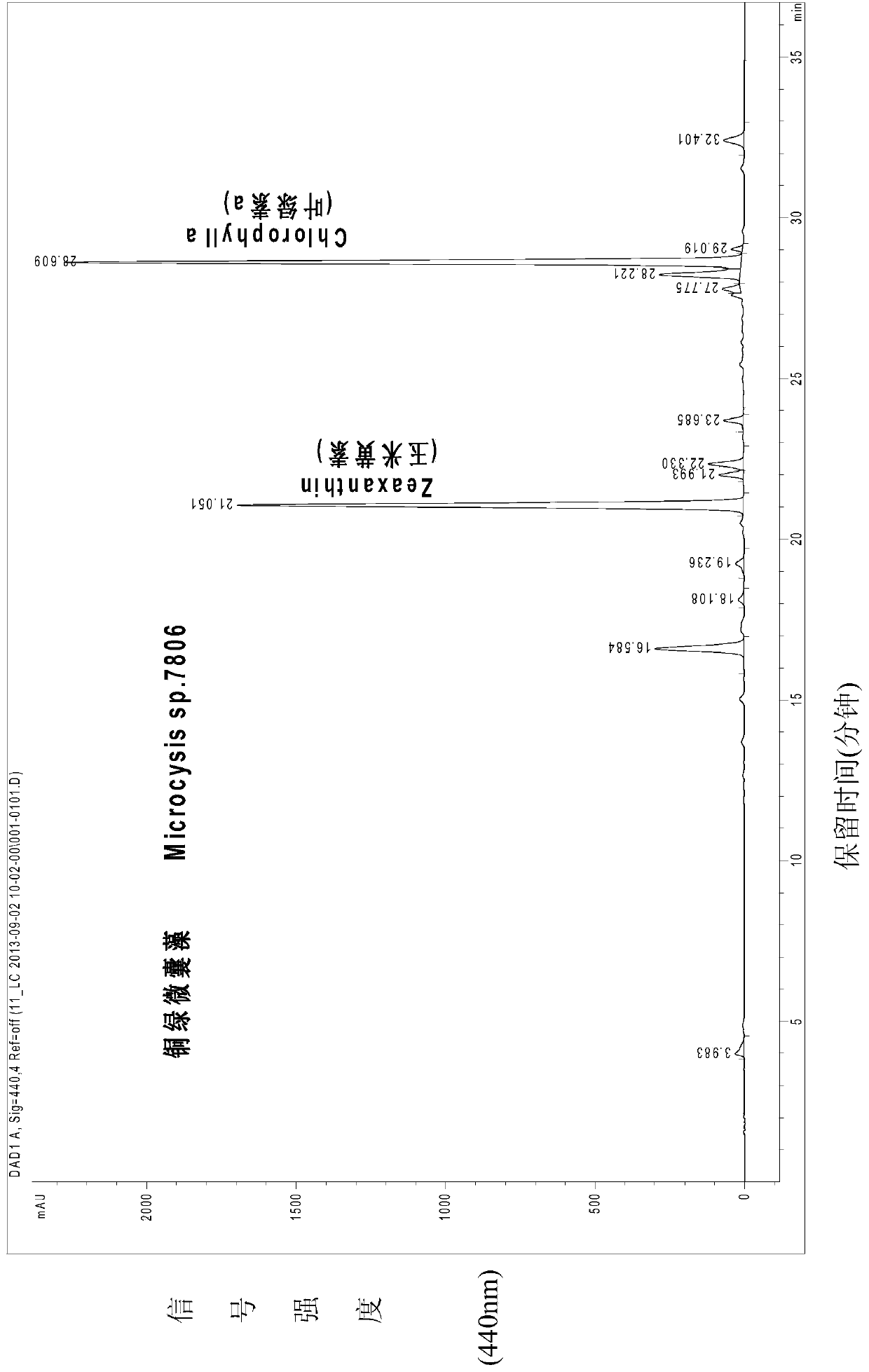

[0053] Example 1. Separation and extraction of Microcystis aeruginosa zeaxanthin standard pigment

[0054] 1) Experimental algae:

[0055] The monocultured Microcystis aeruginosa (Microcystis sp.7806) was selected from the Freshwater Algae Species Bank of the Institute of Hydrobiology, Chinese Academy of Sciences.

[0056] 2) Preparation of quantitative standards for separation and extraction of pigments and photosynthetic pigments:

[0057] A. Cultivation method of experimental algae: the above-mentioned experimental algae with BG11 medium was cultivated in the Laboratory of Aquatic Biodiversity and Environmental Resource Effects of Hubei Normal University under the light intensity of 1000lux and the temperature of 25°C.

[0058] B. Extraction of mixed pigments: Take 300ml of algae liquid in the logarithmic growth phase and collect it through GF / F membrane filtration. The negative pressure of suction filtration is 0.02MPa. The filter membrane is stored at -20°C. Liquid chro...

Embodiment 2

[0067] Example 2. Separation and extraction of Microcystis aeruginosa zeaxanthin standard pigment

[0068] Compared with Example 1, the rest of this example is the same, except that the culture medium of the algae used in the experiment is a CSI medium, and the extraction steps of the mixed pigment are as follows: after accurately counting 300 mL of cultured algae cells, centrifuge them at 5000 rpm / 5 min and collect them in In a 2mL centrifuge tube, after discarding the excess water in the supernatant, add 2.0mL DMF, shake well, and then extract in the refrigerator for 40min, shaking twice during the period. After the pigment is extracted, filter it with a syringe with PTEF, take 0.5mL into the chromatographic bottle, and then add 0.5mL of 1.0M ammonium acetate. This operation is carried out before loading the sample on the chromatograph, so as not to cause flocculent precipitation in the sample .

Embodiment 3

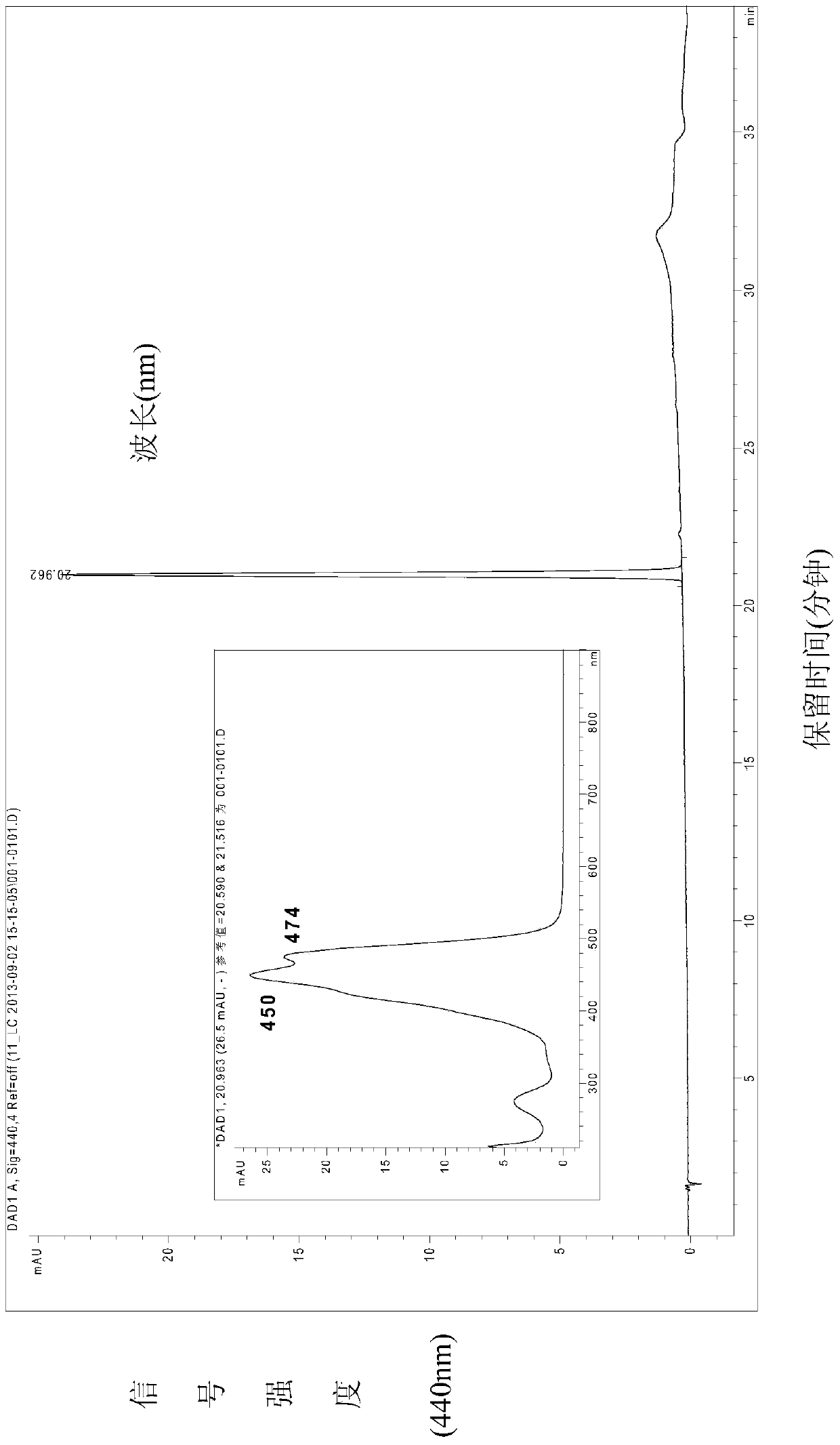

[0069] The making of embodiment 3 zeaxanthin standard pigment working curves

[0070] 1), material:

[0071] From Example 1.

[0072] 2), method:

[0073] A, methods such as pigment extraction and separation see embodiment 1.

[0074] B, the zeaxanthin obtained by separating is measured the absorbance value under its maximum wavelength 450nm under the ultraviolet spectrophotometer, deducts the impurity absorption value at 750nm place, calculates according to the following formula, draws its accurate concentration:

[0075] Carotene: C = A λ max 0.1 × E 1 cm 1 % × d × P c 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com