Luminescent glass for LED and preparation method thereof

A technology of luminescent glass and glass, applied in the field of luminescent materials and their preparation, can solve the problems of high color temperature, impossible to break through the inherent defects of powder materials, low color rendering index, etc., and achieve the effect of solving the technical bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

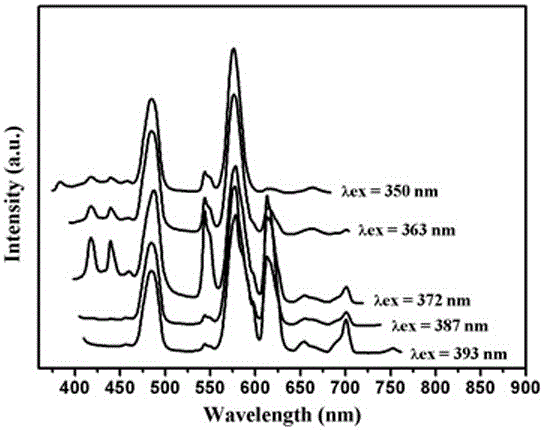

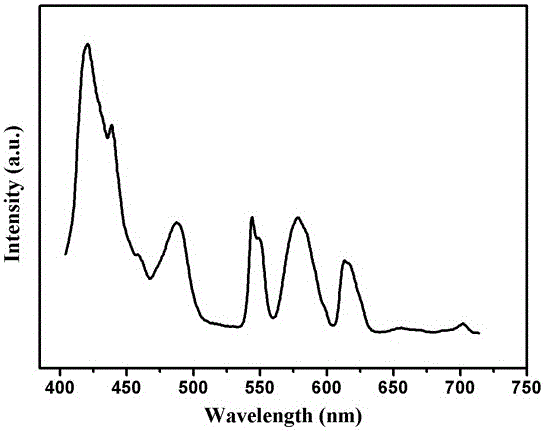

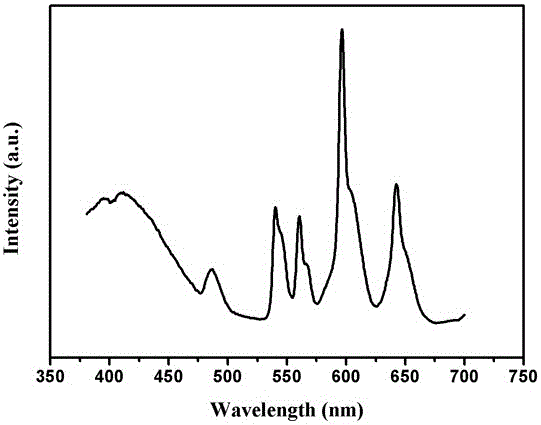

Image

Examples

Embodiment 1

[0024] (1) Design the glass molar composition to be 45SiO 2 −15Al 2 o 3 −10ZnO −20CaF 2 −10CaO: 0.075Eu 2 o 3 , 0.025 Tb 4 o 7 , 0.125Dy 2 o 3 ;

[0025] (2) According to the glass composition designed in step (1), accurately weigh 10.5609 g of silica, 5.9742 g of alumina, 3.1793 g of zinc oxide, 6.0992 g of calcium fluoride, 3.9098 g of calcium carbonate, 0.1031 g of europium oxide, 0.0730 g of terbium and 0.1821 g of dysprosium oxide, these raw materials were fully ground in an agate mortar for 25 min, and the glass batch was obtained after mixing evenly;

[0026] (3) Pour the glass batch material into a corundum crucible, put it into a high temperature furnace for melting, and the melting temperature is 1450 o C, heat preservation for 1 h to obtain glass liquid;

[0027] (4) Pour the glass liquid into 450 o C preheated for 30 min in a stainless steel mold, then placed in a muffle furnace at 450 o C annealed for 2 h, then cooled to room temperature with the f...

Embodiment 2

[0032] (1) Design the glass molar composition to be 45SiO 2 −15Al 2 o 3 −20CaF 2 −10CaO −10Na 2 O: 0.075Eu 2 o 3 , 0.025Tb 4 o 7 , 0.125Dy 2 o 3 ;

[0033] (2) According to the glass composition designed in step (1), accurately weigh 10.2216 g of silica, 5.7822 g of alumina, 5.9032 g of calcium fluoride, 3.7841 g of calcium carbonate, 4.0072 g of sodium carbonate, 0.0998 g of europium oxide, Terbium 0.0707g and Dysprosium oxide 0.1763g, these raw materials are fully ground in an agate mortar for 25 minutes, after mixing evenly, a glass batch is obtained;

[0034] (3) Pour the glass batch material into a corundum crucible, put it into a high temperature furnace for melting, and the melting temperature is 1450 o C, keep warm for 1 h to obtain a uniform glass liquid;

[0035] (4) Pour the glass liquid into 450 o C preheated for 30 min in a stainless steel mold, then placed in a muffle furnace at 450 o C annealed for 2 h, then cooled to room temperature with the fu...

Embodiment 3

[0038] (1) Design the glass molar composition to be 45SiO 2 −15Al 2 o 3 −20B 2 o 3 −10ZnO −10CaO: 0.075Ce 2 o 3 , 0.025Tb 4 o 7 , 0.125Sm 2 o 3 ;

[0039] (2) According to the glass composition designed in step (1), accurately weigh 9.3875 g of silica, 5.3104 g of alumina, 8.5875 g of boric acid, 2.8260 g of zinc oxide, 3.4753 g of calcium carbonate, 0.2262 g of cerium nitrate, and 0.0649 g of terbium oxide. g and 0.1514 g of samarium oxide, fully grind these raw materials in an agate mortar for 25 min, and mix them uniformly to obtain a glass batch;

[0040] (3) Pour the glass batch material into a corundum crucible, put it into a high-temperature furnace for melting, and the melting temperature is 1480 o C, keep warm for 1 h to obtain a uniform glass liquid;

[0041] (4) Pour the glass liquid into 470 o C preheated for 30 min in a stainless steel mold, then placed in a muffle furnace at 470 o C annealed for 2 h, then cooled to room temperature with the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com