Preparation method for 3-methyl-3-butene-1-ol

A technology of butene and methyl, applied in the field of synthesis of fine chemicals, can solve the problems of increased energy consumption, high risk, large reactor volume, etc., and achieves reduced investment and risk, high conversion rate and selectivity , good mass transfer and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

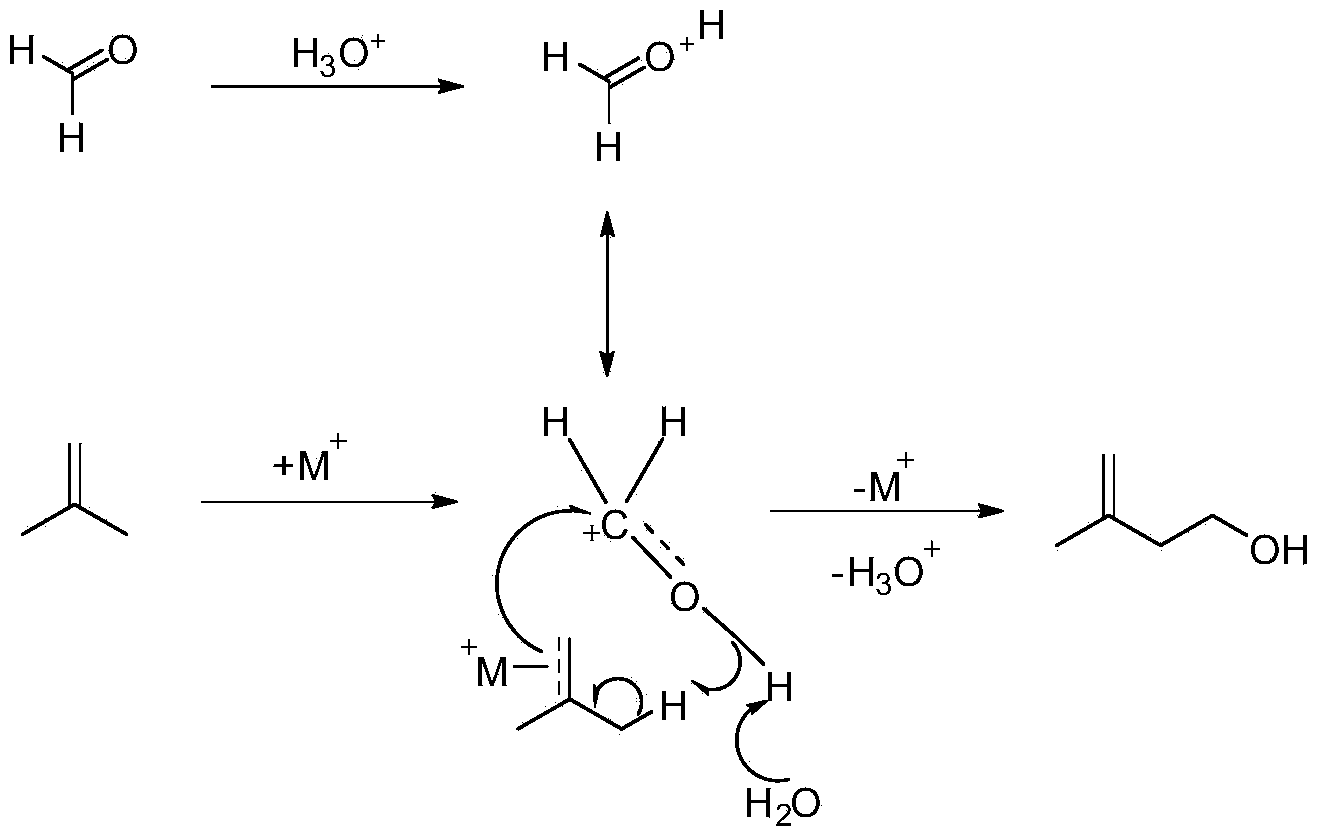

Method used

Image

Examples

Embodiment 1

[0040] The temperature of the tubular reactor is set at 300°C, the reaction system pressure is 8MPa, the flow rate of 0.0023wt% europium nitrate aqueous solution is 11.52g / min, the flow rate of 37wt% formaldehyde aqueous solution is 24g / min, and the flow rate of isobutylene is 16.58g / min min, the residence time of the reaction solution in the reactor is about 3s (the residence time is the reaction time, the same below). Liquid chromatography analysis showed that the formaldehyde conversion rate was 98.02%, and gas chromatography analysis showed that the selectivity of 3-methyl-3-buten-1-ol was 94.33%. (The mass ratio of europium nitrate to formaldehyde is 0.00003:1, the mass ratio of water to formaldehyde is 3:1, and the molar ratio of isobutylene to formaldehyde is 1:1)

Embodiment 2

[0042] Set the temperature of the tubular reactor to 300°C, the pressure of the reaction system to 15MPa, the flow rate of 0.0016wt% europium nitrate aqueous solution to 17.01g / min, the flow rate of 37wt% formaldehyde aqueous solution to 7.3g / min, and the flow rate of isobutylene to 6.05g / min , the residence time of the reaction solution in the reactor is about 15s. Liquid chromatography analysis showed that the formaldehyde conversion rate was 99.11%, and gas chromatography analysis showed that the selectivity of 3-methyl-3-buten-1-ol was 95.06%. (The mass ratio of europium nitrate to formaldehyde is 0.0001:1, the mass ratio of water to formaldehyde is 8:1, and the molar ratio of isobutylene to formaldehyde is 1.2:1)

Embodiment 3

[0044] Set the temperature of the tubular reactor to 330°C, the pressure of the reaction system to 8MPa, the flow rate of 0.0008wt% samarium sulfate aqueous solution to 7.38g / min, the flow rate of 37wt% formaldehyde aqueous solution to 1.5g / min, and the flow rate of isobutylene to 1.04g / min , the residence time of the reaction solution in the reactor is about 15s. Liquid chromatography analysis showed that the formaldehyde conversion rate was 98.76%, and gas chromatography analysis showed that the selectivity of 3-methyl-3-buten-1-ol was 95.44%. (The mass ratio of samarium sulfate to formaldehyde is 0.0001:1, the mass ratio of water to formaldehyde is 15:1, and the molar ratio of isobutylene to formaldehyde is 1:1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com