Silk fibroin/stem cell compounded microsphere and application thereof

A technology of silk fibroin microspheres and composite microspheres is applied in the application field of silk fibroin/stem cell composite microspheres and as injection fillers, which can solve the problem that polymer synthetic materials do not have biocompatibility and lack mechanical and mechanical properties. It can improve structural and functional defects, lasting therapeutic effects, and promote local muscle and nerve regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 silk fibroin microsphere

[0044] 1) Preparation of silk fibroin solution:

[0045] a) Degumming: put silkworm silk (Zhejiang Huazhi Silk Co., Ltd.) into 2M aqueous sodium carbonate solution, bathe in 98°C water for 30 minutes, and wash with purified water. Repeat this process 3 times to remove sericin and leave silk fibroin Protein fibers, drying silk fibroin fibers at 50°C for later use;

[0046] b) Dissolution: Dissolve the above-mentioned dried silk fibroin in 9.3M lithium bromide (LiBr) aqueous solution at a mass volume concentration of 20%, and bathe in water at 60°C for 120 minutes until the silk fibroin is fully dissolved;

[0047] c) Dialysis: Dialyze the mixed solution with a regenerated cellulose dialysis bag (molecular weight cut-off 8000 Daltons), and use purified water 10 times the volume of the silk solution for 10-12 times in 3 days to remove LiBr ions in the solution;

[0048] d) Centrifugation: centrifuge in a horizontal rotor at 5,000g ...

Embodiment 2

[0056] Pass c) in step 2) of Example 1 through an 80-mesh sieve to make silk fibroin microspheres with a particle size of 180 μm, and prepare a suspension of 2 g / ml silk fibroin microspheres and water.

Embodiment 3

[0057] Example 3 Isolation, cultivation and identification of adipose-derived stem cells

[0058] Reference: Shi L B, Cai H X, Chen L K, et al.Tissue engineered bulking agent with adipose-derived stem cells and silk fibroin microspheres for the treatment of intrinsic urethral sphincter deficiency[J].Biomaterials,2014,35(5):1519 -1530.

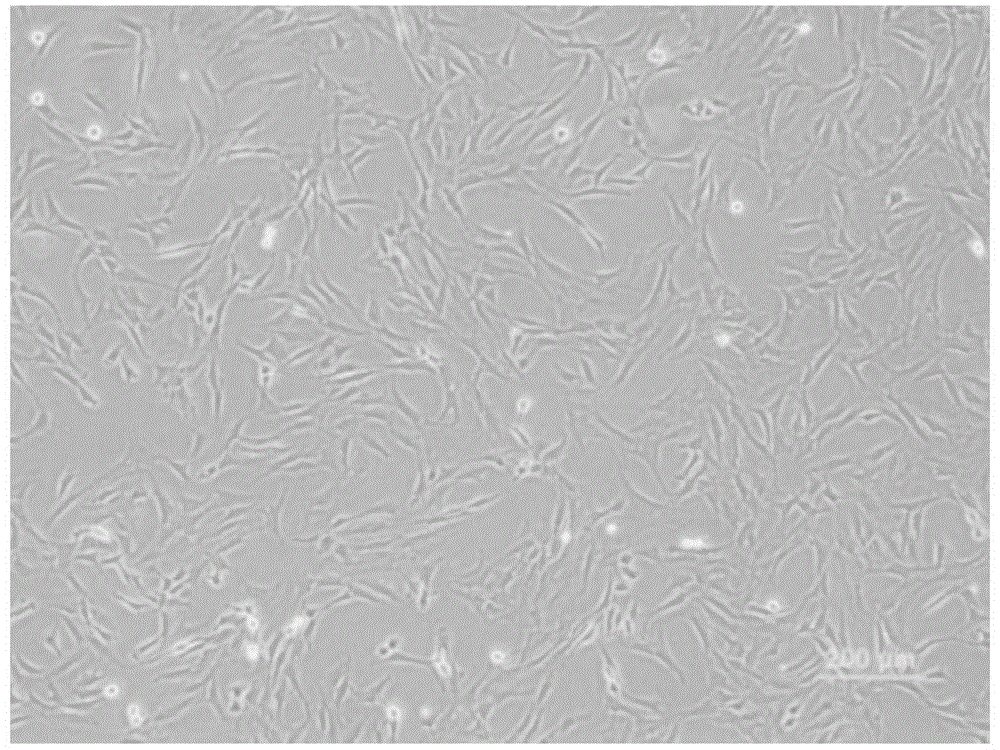

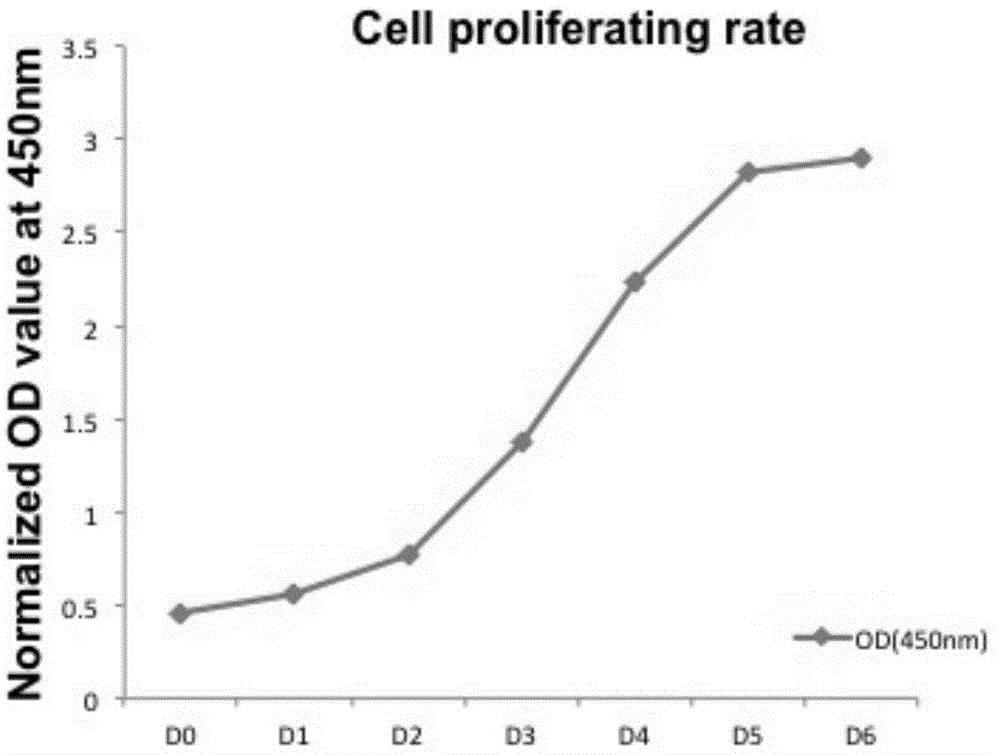

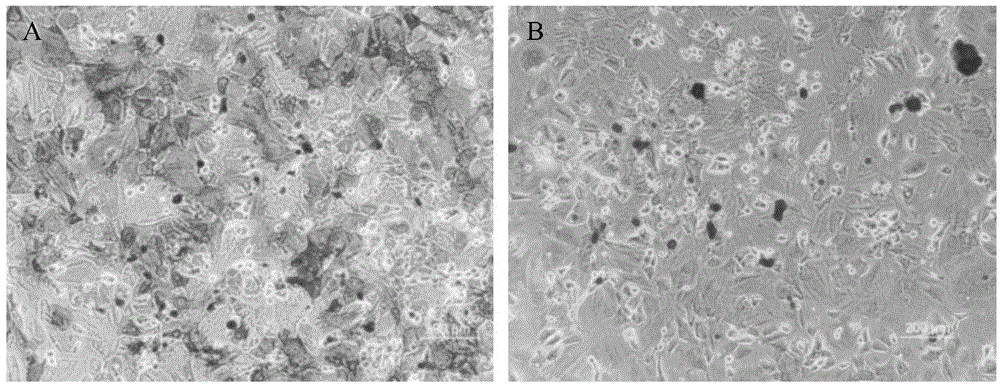

[0059] 1) Isolation and culture of adipose-derived stem cells

[0060] a) 4-week-old female SD rats were anesthetized by intraperitoneal injection of 4% chloral hydrate 4ml / kg, skin was prepared, sterilized by soaking in 75% ethanol for 3min, the inguinal fat pad was cut out, and PBS buffer (pH 7.0) wash 3 times;

[0061] b) Fully shred the fat pad, add 3 times the volume of 0.25% mixed collagenase (Sigma-Aldrich Inc., St. Louis, MO, USA), shake and digest at 37°C for 30 minutes;

[0062] c) Dilute 5 times with DMEM low-sugar medium containing 10% FBS and 1% PS by volume, centrifuge at 1000r / min for 5min, discard the upper layer, remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com