Modified nano silver powder preparing method

A nano-silver powder, modified technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor compatibility, easy agglomeration of nano-silver powder, etc., and achieves low equipment investment and production technology. Simple and easy, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

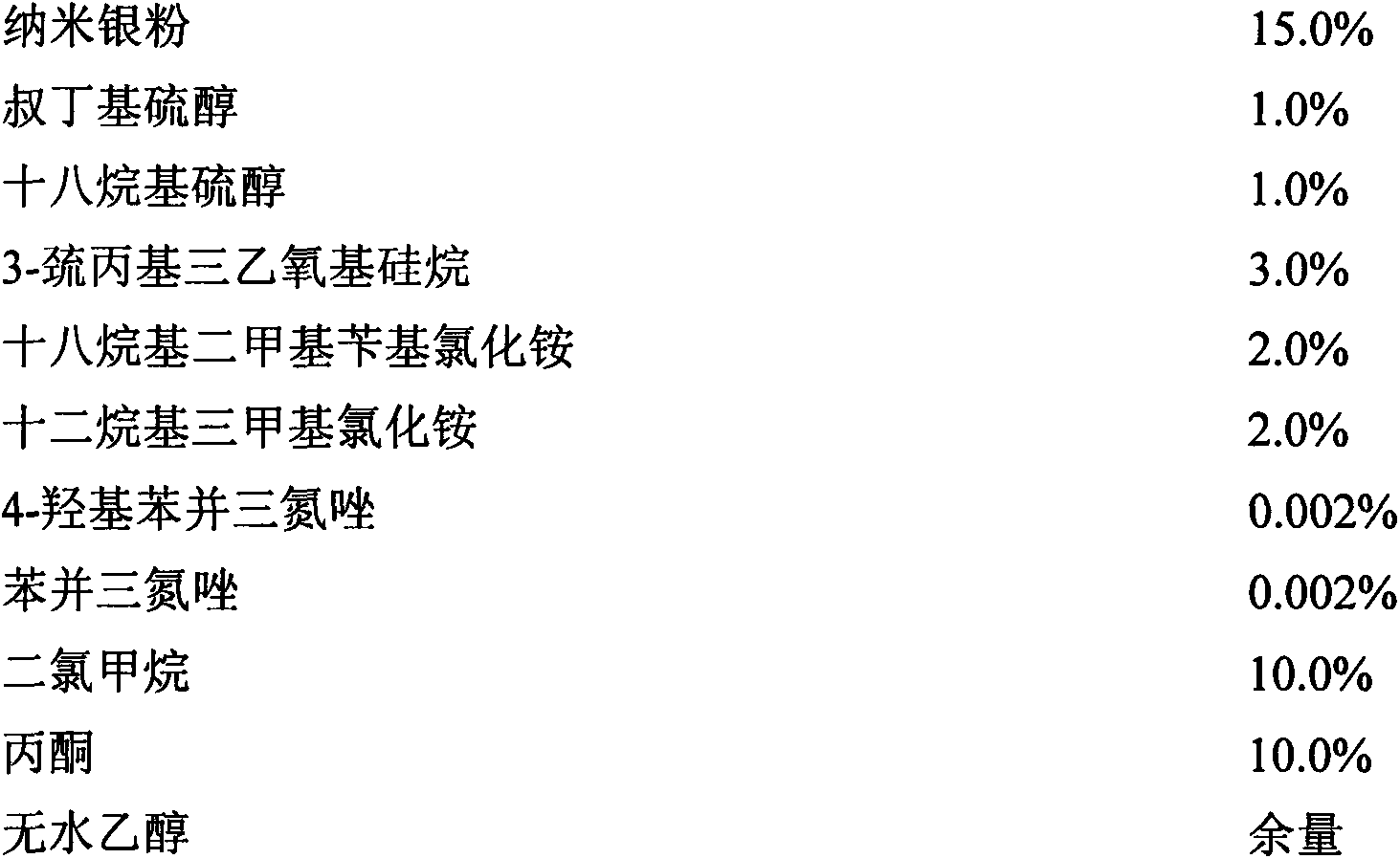

Embodiment 1

[0018]

[0019] According to the above mass percentage, tert-butyl mercaptan, octadecyl mercaptan, 3-mercaptopropyl triethoxysilane, octadecyl dimethyl benzyl ammonium chloride, dodecyl trimethyl Ammonium chloride, 4-hydroxybenzotriazole, benzotriazole, dichloromethane and acetone were added to absolute ethanol, under the action of ultrasonic dispersion with a frequency of 25kHz and a power of 2kW, after stirring for 0.4h, Then add nano-silver powder, and further stir for 6.0h under the action of ultrasonic dispersion with a frequency of 25kHz and a power of 2kW, and then undergo centrifugation, anhydrous ethanol washing, centrifugal separation, deionized water washing, centrifugal separation, vacuum drying, and grinding and sieving process to prepare modified nano-silver powder.

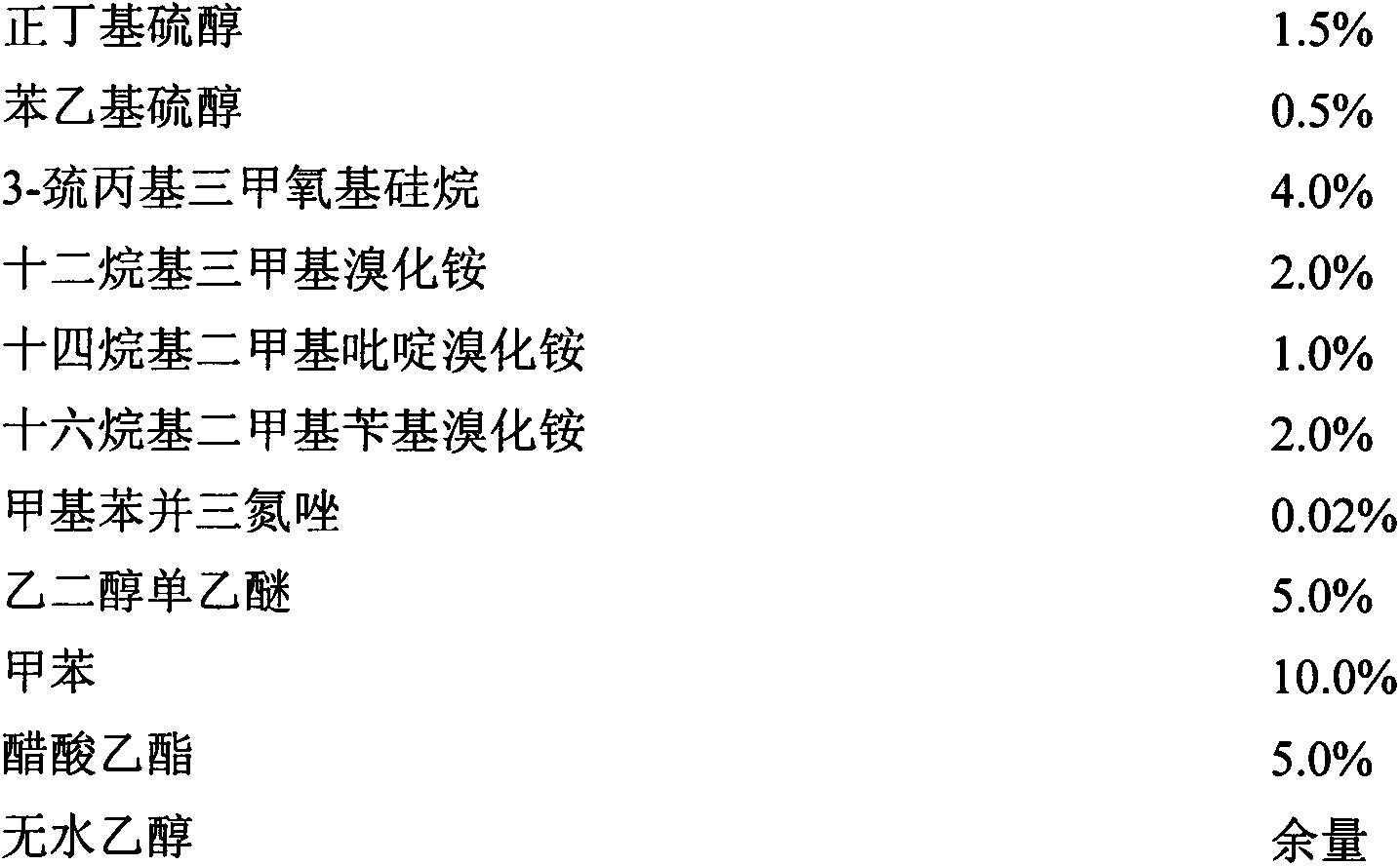

Embodiment 2

[0021]

[0022]

[0023] According to the above mass percentage, n-butyl mercaptan, phenethyl mercaptan, 3-mercaptopropyltrimethoxysilane, dodecyltrimethylammonium bromide, and tetradecyllutidine were brominated sequentially Ammonium, cetyl dimethyl benzyl ammonium bromide, methyl benzotriazole, ethylene glycol monoethyl ether, toluene and ethyl acetate are added to absolute ethanol, and the frequency is 28kHz, the power is 2.5kW Under the action of ultrasonic dispersion, stir for 0.3h, then add nano-silver powder, and then stir for 5.0h under the action of ultrasonic dispersion with a frequency of 28kHz and a power of 2.5kW, and then go through centrifugation, absolute ethanol washing, centrifugation, and dehydration in sequence. The modified nano-silver powder is prepared through ion water washing, centrifugal separation, vacuum drying, grinding and sieving.

Embodiment 3

[0025]

[0026] According to the above mass percentage, n-dodecyl mercaptan, n-pentyl mercaptan, 3-mercaptopropyltriethoxysilane, dodecyldimethylbenzyl ammonium chloride, octadecyltri Add methylammonium bromide, N-hydroxybenzotriazole, benzotriazole, carbon tetrachloride and methyl ethyl ketone into absolute ethanol, and stir for 0.5 After h, add nano-silver powder, and then stir for 4.0 h under the action of ultrasonic dispersion with a frequency of 60 kHz and a power of 3 kW, and then successively undergo centrifugal separation, absolute ethanol washing, centrifugal separation, deionized water washing, centrifugal separation, vacuum Drying, grinding and sieving processes prepare the modified nanometer silver powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com