Magnetic modified sodium alginate flocculating agent

A technology of sodium alginate and flocculant, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of inability to completely separate metals, low mechanical strength, poor sample selection, etc., and achieve fast and clean separation effect, good adsorption and flocculation effect, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

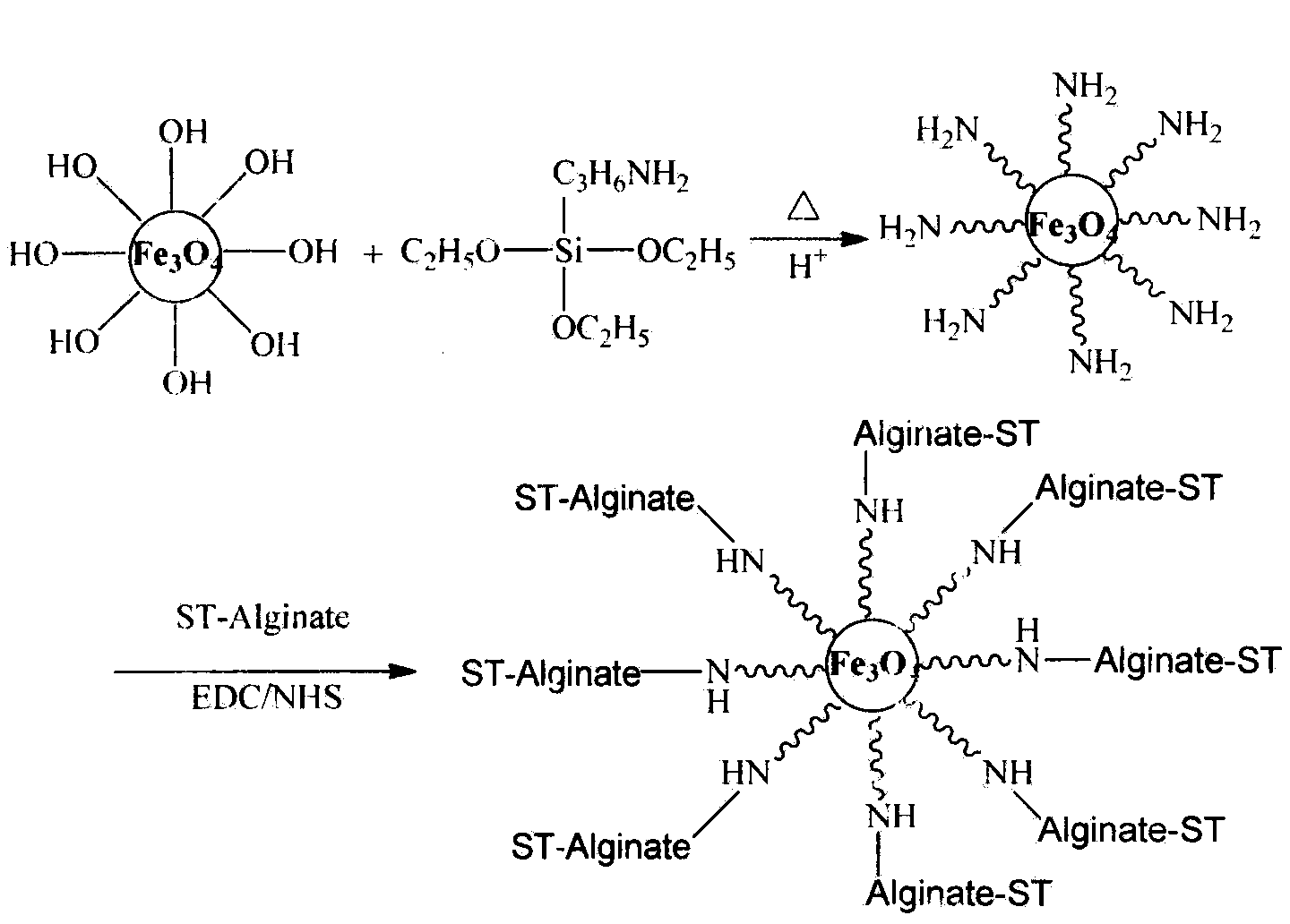

[0025] FeCl 3 ·6H 2 O was dissolved in distilled water to prepare a 0.5 mol / L ferric chloride solution. Take 44mL of ferric chloride solution (0.5molL -1 ) in a 250mL three-necked flask, add 3.5g of FeCl 2 4H 2 O is completely dissolved, blow nitrogen for 30min, and slowly add 110mL of NaOH solution (1.0mol L -1 ), stirred vigorously at 60°C for 1h, then raised the temperature to 80°C and matured for 1h, washed twice with water and ethanol respectively to obtain Fe 3 o 4 magnetic nanoparticles.

Embodiment 2

[0027] Prepare the aqueous solution of 100ml ethanol (volume ratio 1: 1) as dispersion medium, transfer in the 250mL three-neck flask, the Fe of 2g 3 o 4 Disperse the nanoparticles in the aqueous solution of ethanol, add a small amount of glacial acetic acid dropwise to adjust the pH value to be acidic, pass nitrogen gas for 30 minutes, slowly add 12mL of KH-550 with a separatory funnel, keep the system closed, stir vigorously at 40°C for 4 hours, and the reaction is complete Finally, the nanoparticles were separated by a magnet, washed twice with absolute ethanol, and dried under vacuum at 40 °C to obtain amino-modified Fe 3 o 4 Nanoparticles (Fe-NH 2 ).

Embodiment 3

[0029] Under the condition of 4℃~8℃ protected from light, SA was oxidized by sodium periodate to prepare partially oxidized sodium alginate OSA with a yield of 87%. Dissolve 8g of OSA in 80mL of phosphate buffer (pH=7), add 100mL of a certain concentration of TSC aqueous solution, stir and react at 40°C for 4h, cool to 20°C and add appropriate amount of NaBH in batches 4 , complete reaction 24h. The product was precipitated with ethanol, filtered with suction, soaked with ethanol again, and filtered with suction, and this process was repeated four times, and dried in vacuum at 30°C for 24 hours to obtain light yellow powder flocculant thiosemicarbazide-sodium alginate ST.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com