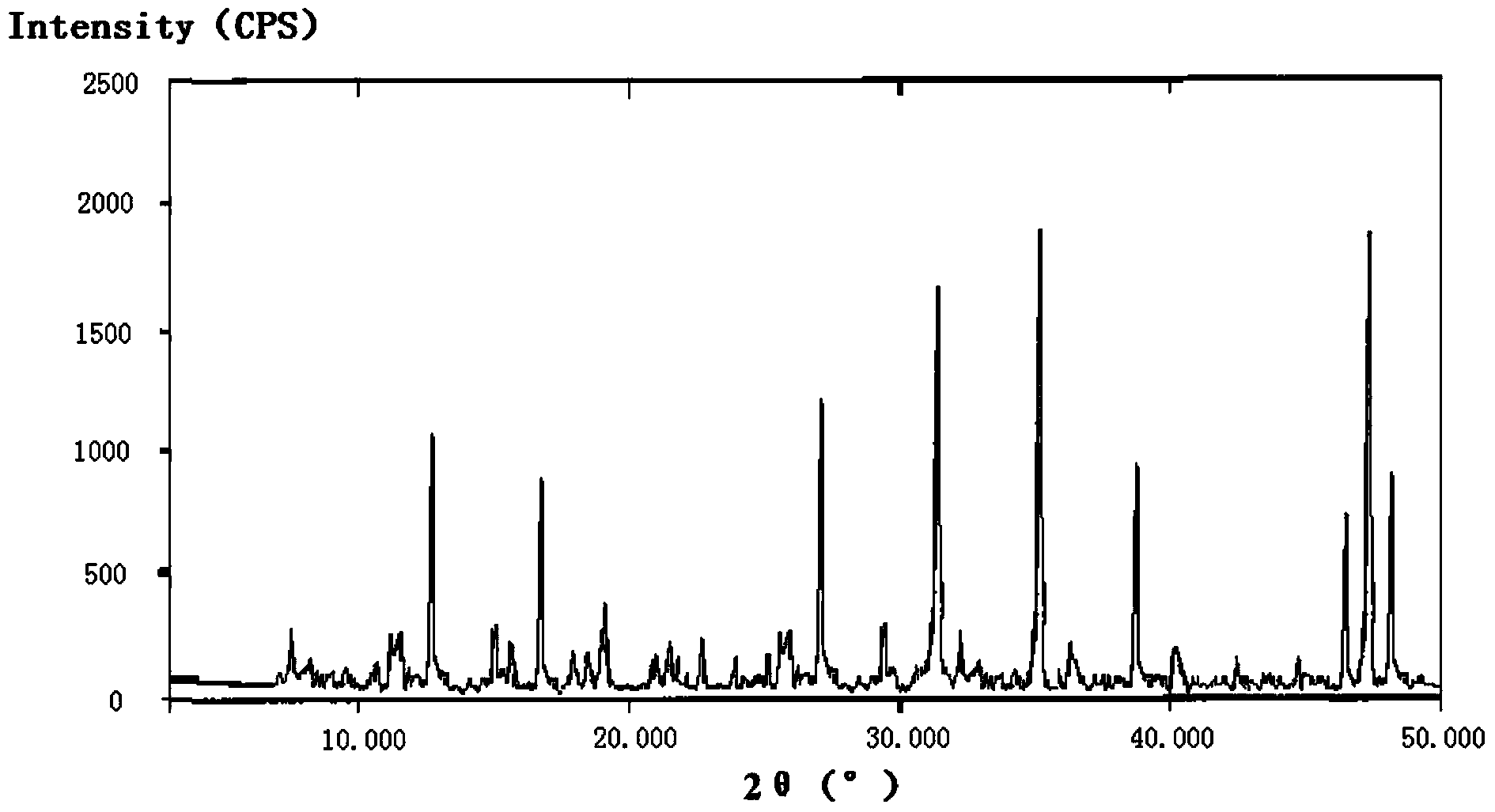

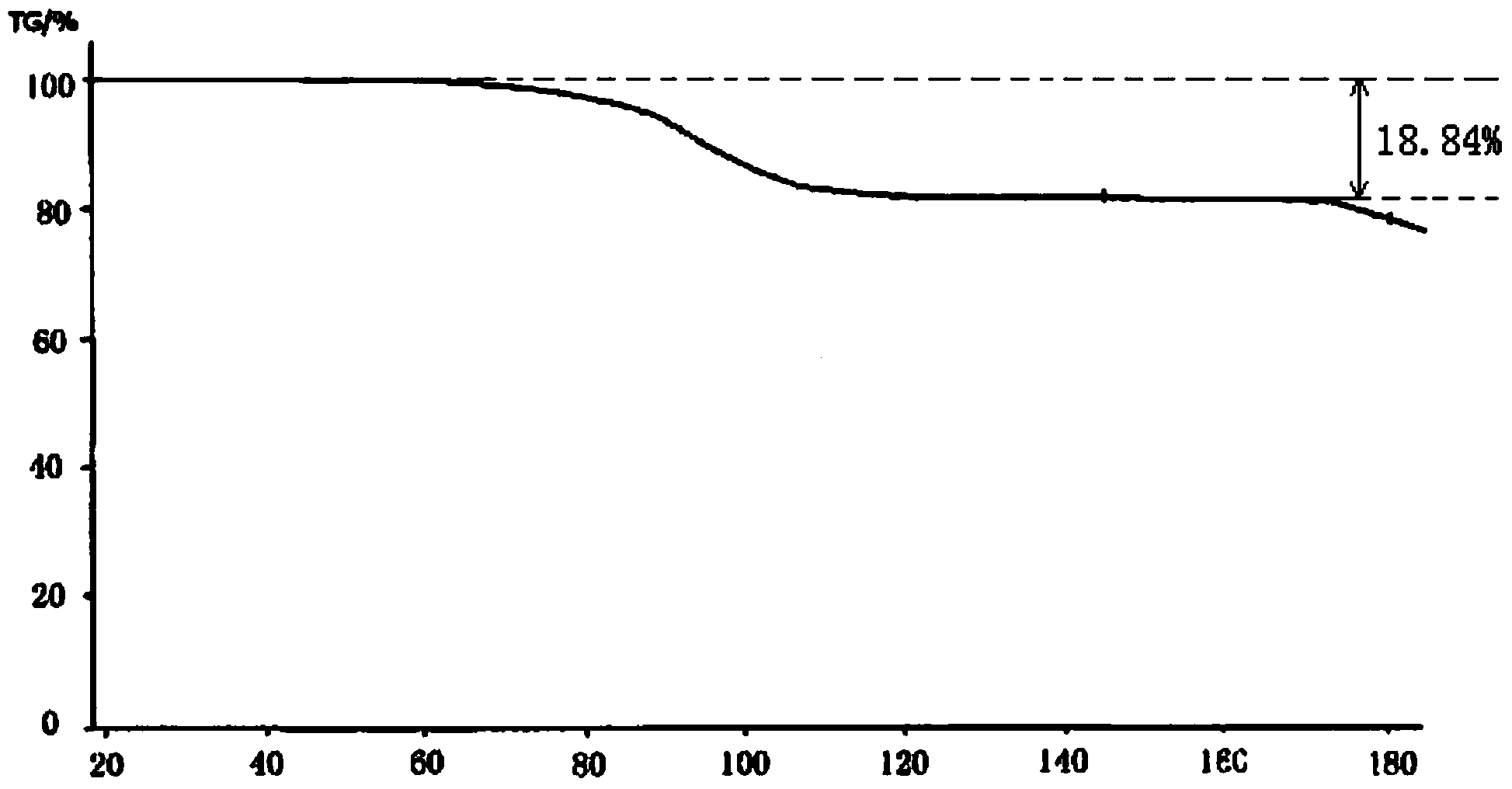

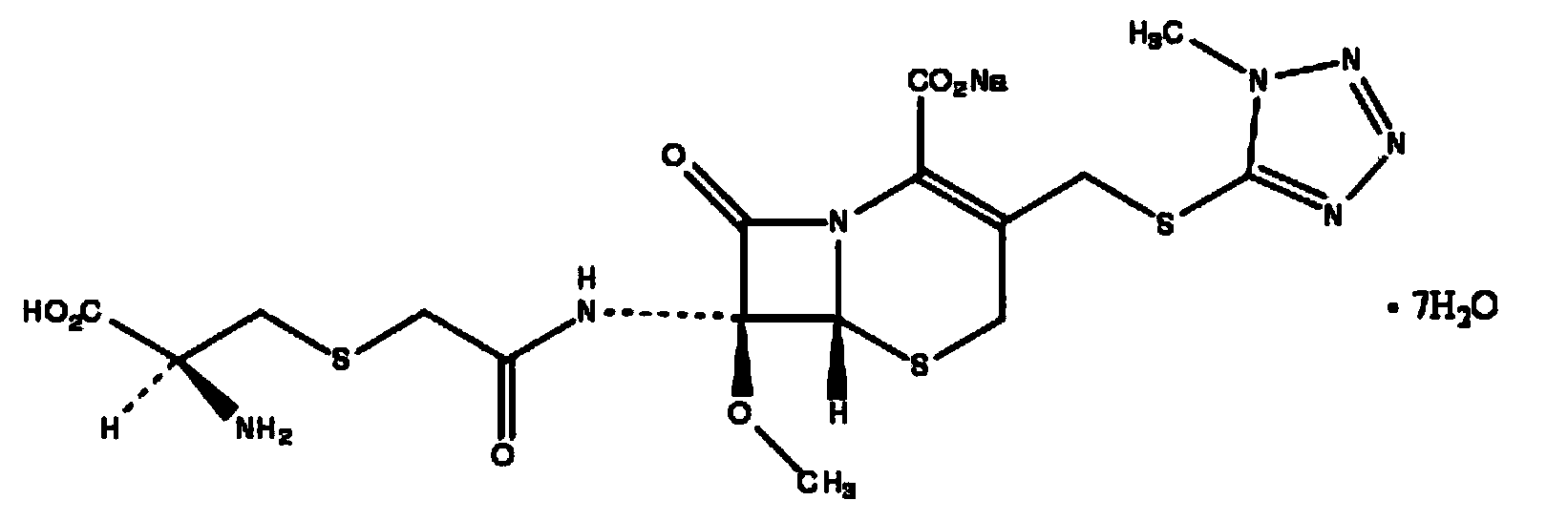

Cefminox sodium crystal form compound

A technology of cefminox sodium and compound, applied in the field of medicine, can solve the problems of local circulation disorder, blockage of blood supply, allergic reaction, etc., and achieves the effect that the number of insoluble particles changes little, is beneficial to use and operation, and shortens the dissolution time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the preparation of cefminox sodium crystal form compound

[0043] 1) Preparation of solution A: Sterile filter 600L of mixed solvent A of ether and acetonitrile (the volume ratio of ether and acetonitrile is 5:1) into a crystallization tank, and cool down to 8°C for use, which is solution A;

[0044] 2) Preparation of solution B: at room temperature, add 60L of mixed solvent B of water and 1,4-dioxane (the volume ratio of water and 1,4-dioxane is 6:1) In the dissolution tank, add 30 kg of cefminox sodium crude product, add 0.45 kg of activated carbon after dissolving, stir for decolorization for 30 min, filter aseptically, wash with 10 kg of water for injection, collect filtrate and washing liquid, and obtain B solution;

[0045] 3) Add solution B to solution A, cool down to 12°C, keep the temperature, and stir at a stirring speed of 20 rpm for 25-35 minutes;

[0046] 4) Then lower the temperature to 2°C, control the stirring speed to 12 rpm, control the ...

Embodiment 2

[0049] Embodiment 2, the preparation of cefminox sodium crystal form compound

[0050] 1) Preparation of solution A: Sterile filter 600L of mixed solvent A of ether and acetonitrile (the volume ratio of ether and acetonitrile is 3:1) into a crystallization tank, cool down to 5°C and wait for use, which is solution A;

[0051] 2) Preparation of solution B: at room temperature, add 60L of mixed solvent B of water and 1,4-dioxane (the volume ratio of water and 1,4-dioxane is 5:1) In the dissolving tank, add 30 kg of cefminox sodium crude product, add 0.45 kg of activated carbon after dissolving, stir and decolorize for 25 min, filter aseptically, wash with 10 kg of water for injection, collect the filtrate and washing liquid, and obtain B solution;

[0052] 3) Add solution B to solution A, cool down to 10°C, keep the temperature, and stir at a stirring speed of 18 rpm for 25-35 minutes;

[0053] 4) Then lower the temperature to 0°C, control the stirring speed to 10 rpm, control ...

Embodiment 3

[0055] Embodiment 3, the preparation of cefminox sodium crystal form compound

[0056] 1) Prepare A solution: Sterile filter 600L of mixed solvent A of ether and acetonitrile (the volume ratio of ether and acetonitrile is 8:1) into a crystallization tank, cool down to 10°C and wait for use, which is A solution;

[0057] 2) Preparation of solution B: at room temperature, add 100L of mixed solvent B of water and 1,4-dioxane (where the volume ratio of water and 1,4-dioxane is 7:1) In the dissolving tank, add 30 kg of cefminox sodium crude product, add 0.45 kg of activated carbon after dissolving, stir and decolorize for 35 min, filter aseptically, wash with 10 kg of water for injection, collect filtrate and washing liquid, and obtain B solution;

[0058] 3) Add solution B to solution A, cool down to 15°C, keep the temperature, and stir at a stirring speed of 22 rpm for 25-35 minutes;

[0059] 4) Then lower the temperature to 5°C, control the stirring speed to 15 rpm, control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com