GC-MS/MS (gas chromatography-mass spectrometer/mass spectrometer) technique-based method for analyzing migration volume from photoinitiator to MPPO (modified polyphenylene oxide) in printing packaging paper

A technology of photoinitiator and technical analysis, applied in the direction of analysis of materials, measurement devices, material separation, etc., can solve the problem of no photoinitiator specific migration analysis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

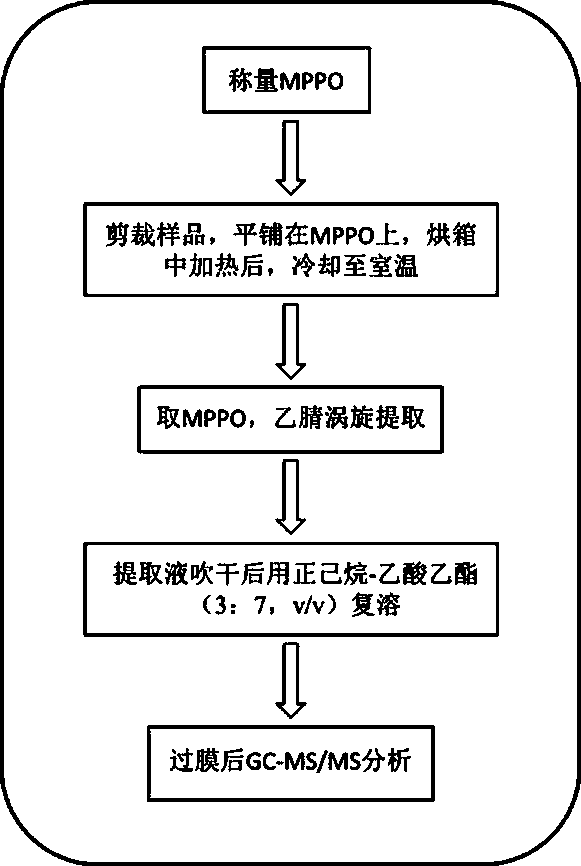

Method used

Image

Examples

example 1

[0033] 1. Instruments and reagents:

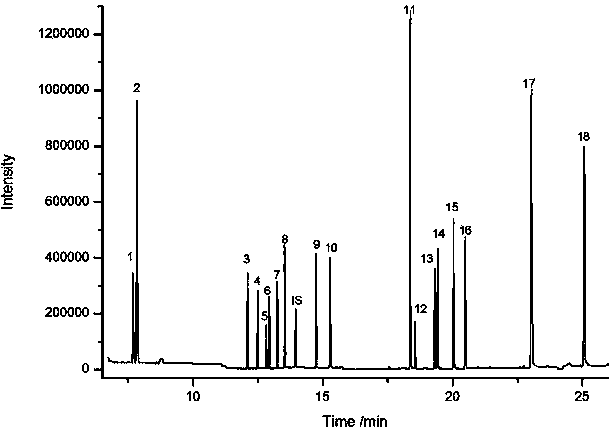

[0034] 18 photoinitiators: 2-hydroxy-2-methyl-1-phenylacetone, methyl benzoylformate, benzophenone, 2-methylbenzophenone, 1-hydroxycyclohexylphenylmethanone Ketone (photoinitiator 184), ethyl p-N,N-dimethylaminobenzoate, 3-methylbenzophenone, 4-methylbenzophenone, 2,2-dimethoxy-2 -Phenylacetophenone (benzoin dimethyl ether), methyl phthaloylbenzoate, isooctyl p-dimethylaminobenzoate, 2-methyl-1-(4-methylthio)phenyl 2- Morpholinyl-1-propanone (photosensitizer 907), 4-isopropylthioxanthone, 2-isopropylthioxanthone, biphenylbenzophenone, 2,4-diethylthioxanthone Ketone (photoinitiator DETX), 4,4-bis(dimethylamino)benzophenone (Michler's ketone), 4,4-bis(diethylamino)benzophenone (tetraethylmichler's ketone) , internal standard: deuterated anthracene, all analytically pure; acetonitrile, acetone, n-hexane, ethyl acetate, methanol, all chromatographic grade reagents; distilled water, in line with the requirements of first-grade water in GB / T ...

example 2

[0055] As described in Example 1, transfer the modified polyphenylene ether simulant that has completed the migration experiment into a centrifuge tube with a stopper, add 10 mL of acetonitrile extractant, and take different vortex times (namely 2min, 5min, 7min and 10min) for one time Extraction and two extractions, compare the difference in the extraction effect of 70 ° C water bath for 24 hours, the extract was dried and reconstituted, filtered for GC-MS / MS analysis. The differences in the extraction effects of different vortex extraction times compared with 70°C water bath for 24 hours were all within plus or minus 10%, and the differences in the extraction effects of vortex extraction once and twice compared with 70°C water bath for 24 hours were mostly within 10%. Then use 10min vortex extraction once to achieve the purpose of extraction.

[0056]

example 3

[0058] As can be seen from Example 1, since the minimum limit of the photoinitiator involved is 0.01 mg / kg, which fully meets the sensitivity requirements of the method, 1 g MPPO can be used in the pretreatment process instead of 4 g MPPO in the EU standard. Since MPPO is expensive and the recycling process is cumbersome, reducing the amount of MPPO used in the pretreatment process also reduces the cost under the premise of meeting the sensitivity requirements. This example compares the area of the packaging sample used in the migration experiment with the mass ratio of the modified polyphenylene ether simulant, respectively 1dm 2 : 4g and 0.25dm 2 : the amount of migration in two situations of 1g, the experimental results are shown in Table 4, as can be seen from the experimental results, there is no significant difference in the ratio of two kinds of migration experiments, and this method can be used to use the area and modification of the packaging samples for migration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com