Production method of polystyrene insulation board

A production method and polystyrene technology, applied in the field of building materials, can solve the problems of uneven material and poor adhesion of polystyrene particles, and achieve the effect of simple process and improved compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

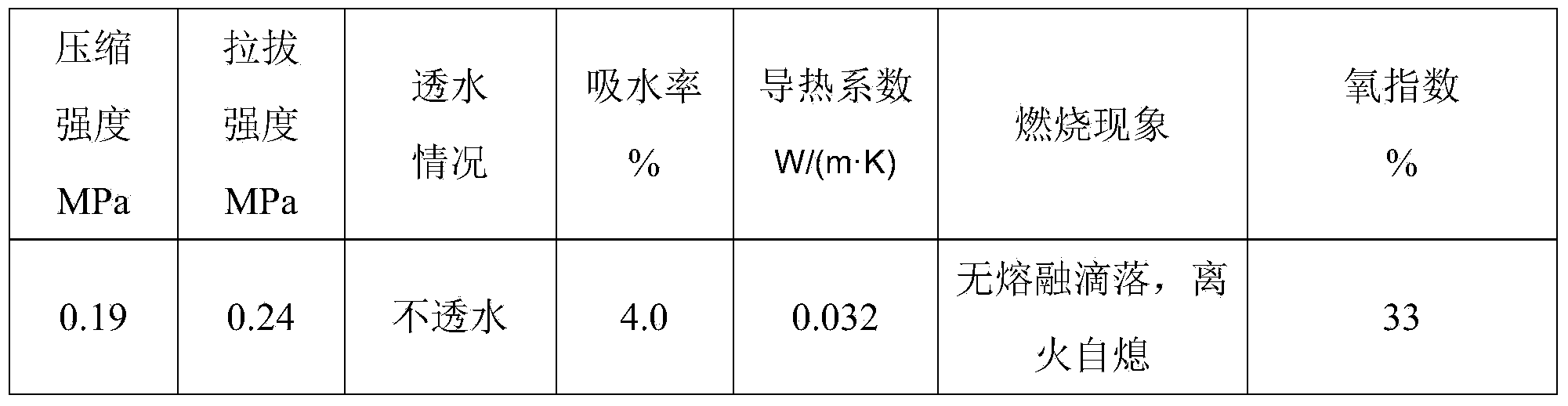

Embodiment 1

[0026] The ordinary grade E-303 expandable polystyrene particles were pre-expanded for 15 minutes under a steam pressure of 0.3 MPa to obtain polystyrene beads with a particle size of 6-8 mm.

[0027] Dry-mix 5 parts by weight of expandable graphite and 2 parts by weight of microencapsulated red phosphorus, and fully mix 2 parts by weight of n-pentane, 3 parts by weight of polyoxyethylene ether, and 5 parts by weight of p-toluenesulfonic acid to obtain a liquid Auxiliary.

[0028] 40 parts by weight of phenolic resin with a viscosity of 1000 will be added to 80 parts by weight of polystyrene beads placed in the mixing bin, and fully mixed so that the resin is evenly coated on the surface of the beads. Pour in the liquid auxiliaries, continue to stir, and mix well. Then pour the above flame retardant dry blend and mix evenly.

[0029] The pellets are poured into a molding machine in a wet state for mechanical compression to reduce the volume compression by 10%, and then molde...

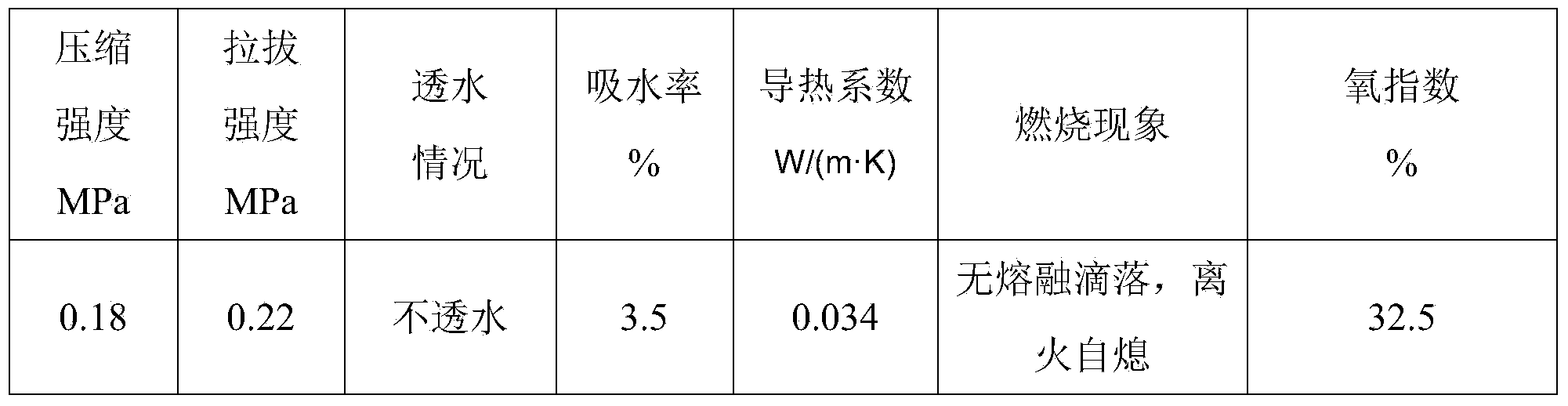

Embodiment 2

[0033] The ordinary grade E-303 expandable polystyrene particles were pre-expanded for 35 minutes under the steam pressure of 0.1 MPa to obtain polystyrene beads with a particle size of 5-7mm.

[0034] 8 parts by weight of aluminum hydroxide powder and 4 parts by weight of MCA were dry mixed evenly. 5 parts by weight of petroleum ether, 1 part by weight of cyclopentane, 8 parts by weight of polyoxyethylene sorbitan monooleate, and 9 parts by weight of hydrochloric acid were fully mixed to prepare a liquid additive.

[0035] Add 90 parts by weight of furan resin with a viscosity of 2000 into the mixing bin containing 90 parts by weight of polystyrene particles, mix well and coat evenly. Pour in the liquid auxiliaries, continue to stir, and mix well. Then pour the above flame retardant dry blend and mix evenly.

[0036] The pellets are poured into a molding machine in a wet state for mechanical compression to reduce the volume compression by 12%, and then molded under a pressure...

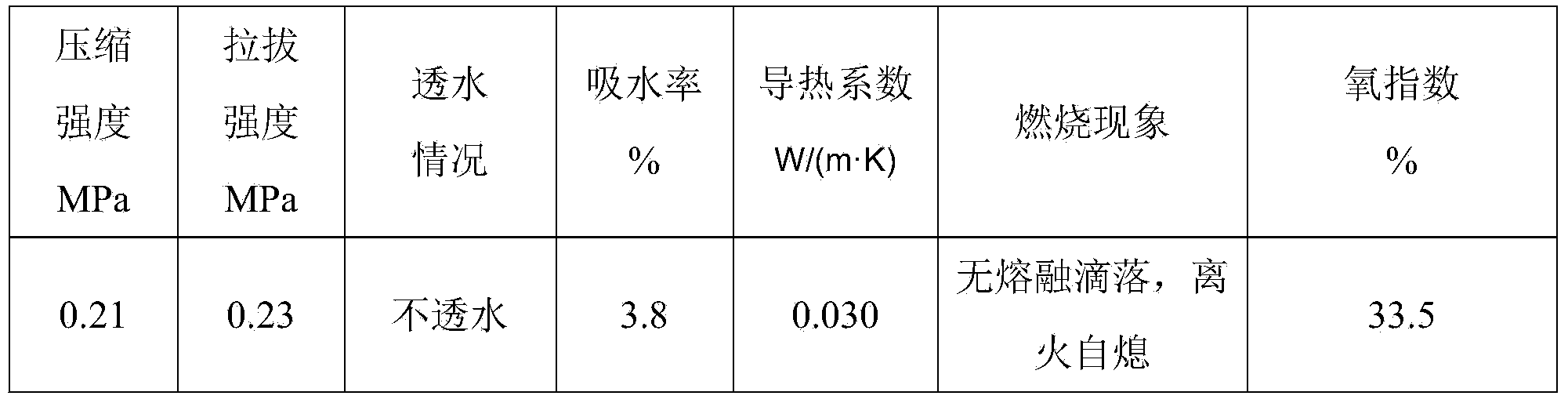

Embodiment 3

[0040] The ordinary grade E-303 type expandable polystyrene particles were pre-expanded for 20 minutes under a steam pressure of 0.2 MPa to obtain polystyrene beads with a particle diameter of 4-6 mm, counted as 70 parts by weight.

[0041] 5 parts by weight of decabromodiphenyl ether, 3 parts by weight of zinc borate and 3 parts by weight of microencapsulated red phosphorus are dry-mixed uniformly. 3 parts by weight of dichloromethane, 2 parts by weight of isopentane, 5 parts by weight of castor oil polyoxyethylene ether, and 8 parts by weight of sulfuric acid are fully mixed to prepare a liquid additive.

[0042] Add 50 parts by weight of urea-formaldehyde resin with a viscosity of 800 into the mixing bin containing 70 parts by weight of polystyrene particles, mix well and coat evenly. Pour in the liquid auxiliaries, continue to stir, and mix well. Then pour the above flame retardant dry blend and mix evenly.

[0043] The pellets are poured into a molding machine in a wet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com