Apatite type silicate terbium magneto-optical crystal and preparation method thereof

A technology of magneto-optic crystal and terbium silicate, which is applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problem of no breakthrough in high-quality TGG crystal growth technology, expensive raw materials for TGG crystal synthesis, and unfavorable magneto-optical devices. Miniaturization and other issues, to achieve excellent magneto-optical effect, to achieve large-scale low-cost mass production, and short cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

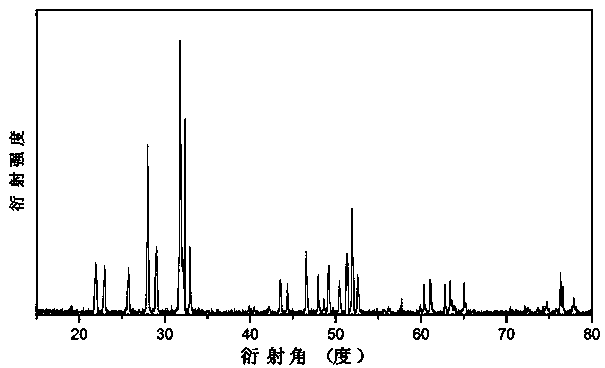

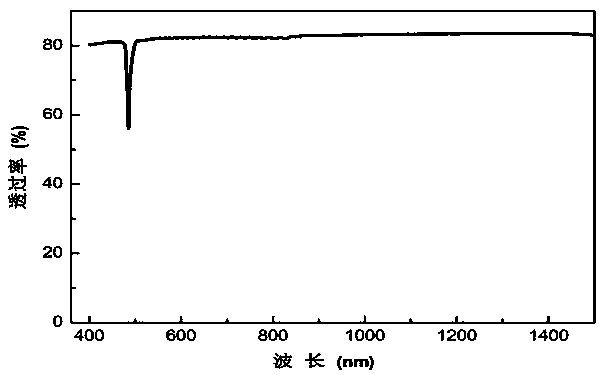

[0017] Embodiment 1: growth of apatite type Tb by melt pulling method 9.33 (SiO 4 ) 6 o 2 Magneto-optic crystals.

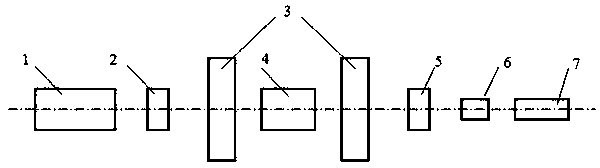

[0018] will press Tb 9.33 (SiO 4 ) 6 o 2 Stoichiometric ratio of accurately weighed Tb 4 o 7 (99.99%), SiO 2 (99.95%) was put into a corundum mortar, mixed and ground evenly, and after tableting, it was placed in a muffle furnace at 900°C for 12 hours for solid-state reaction. After taking it out, grind it again, press it into tablets, raise the temperature to 1400° C. and carry out the solid phase reaction again for 16 hours to obtain the initial raw material for crystal growth. The size is φ60×40mm 3 The iridium crucible is used as a container for crystal growth, and the synthesized polycrystalline powder raw material is put into the container, put into a single crystal pulling furnace, and heated in N 2 Single crystal pulling is carried out under atmosphere. The growth temperature is 1900° C., the growth rate is 0.5 mm / h, and the crystal rotation ...

Embodiment 2

[0020] Embodiment 2: growth of apatite type Tb by melt pulling method 9 (SiO 4 ) 6 o 1.5 Magneto-optic crystals.

[0021] will press Tb 9 (SiO 4 ) 6 o 1.5 Stoichiometric ratio of accurately weighed Tb 4 o 7 (99.99%), SiO 2 (99.95%) was put into a corundum mortar, mixed and ground evenly, and after being pressed into tablets, it was placed in a muffle furnace at 900°C for 20 hours of solid-state reaction. After taking it out, grind it again, press it into tablets, raise the temperature to 1400° C. and carry out the solid phase reaction again for 24 hours to obtain the initial raw material for crystal growth. The size is φ60×40mm 3 The iridium crucible is used as a container for crystal growth, and the synthesized polycrystalline powder raw material is put into the container, put into a single crystal pulling furnace, and heated in N 2 Single crystal pulling is carried out under atmosphere. The growth temperature is 2000° C., the growth rate is 2.0 mm / h, and the cry...

Embodiment 3

[0022]Embodiment 3: growth of apatite type Tb by melt pulling method 9.66 (SiO 4 ) 6 o 2.5 Magneto-optic crystals.

[0023] will press Tb 9.66 (SiO 4 ) 6 o 2.5 Stoichiometric ratio of accurately weighed Tb 4 o 7 (99.99%), SiO 2 (99.95%) was put into a corundum mortar, mixed and ground evenly, and after being pressed into tablets, it was placed in a muffle furnace at 900°C for 20 hours of solid-state reaction. After taking it out, grind it again, press it into tablets, raise the temperature to 1400° C. and carry out the solid phase reaction again for 24 hours to obtain the initial raw material for crystal growth. The size is φ60×40mm 3 The iridium crucible is used as a container for crystal growth, and the synthesized polycrystalline powder raw material is put into the container, put into a single crystal pulling furnace, and heated in N 2 Single crystal pulling is carried out under atmosphere. The growth temperature is 1950° C., the growth rate is 1 mm / h, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com