Preparation method of self-assembly nanofiltration separation membrane for high salinity and high ammonia nitrogen wastewater

A high ammonia nitrogen, nanofiltration membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology and other directions, can solve problems such as membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A typical high-salinity waste liquid: trona mother liquor recovery nanofiltration membrane process:

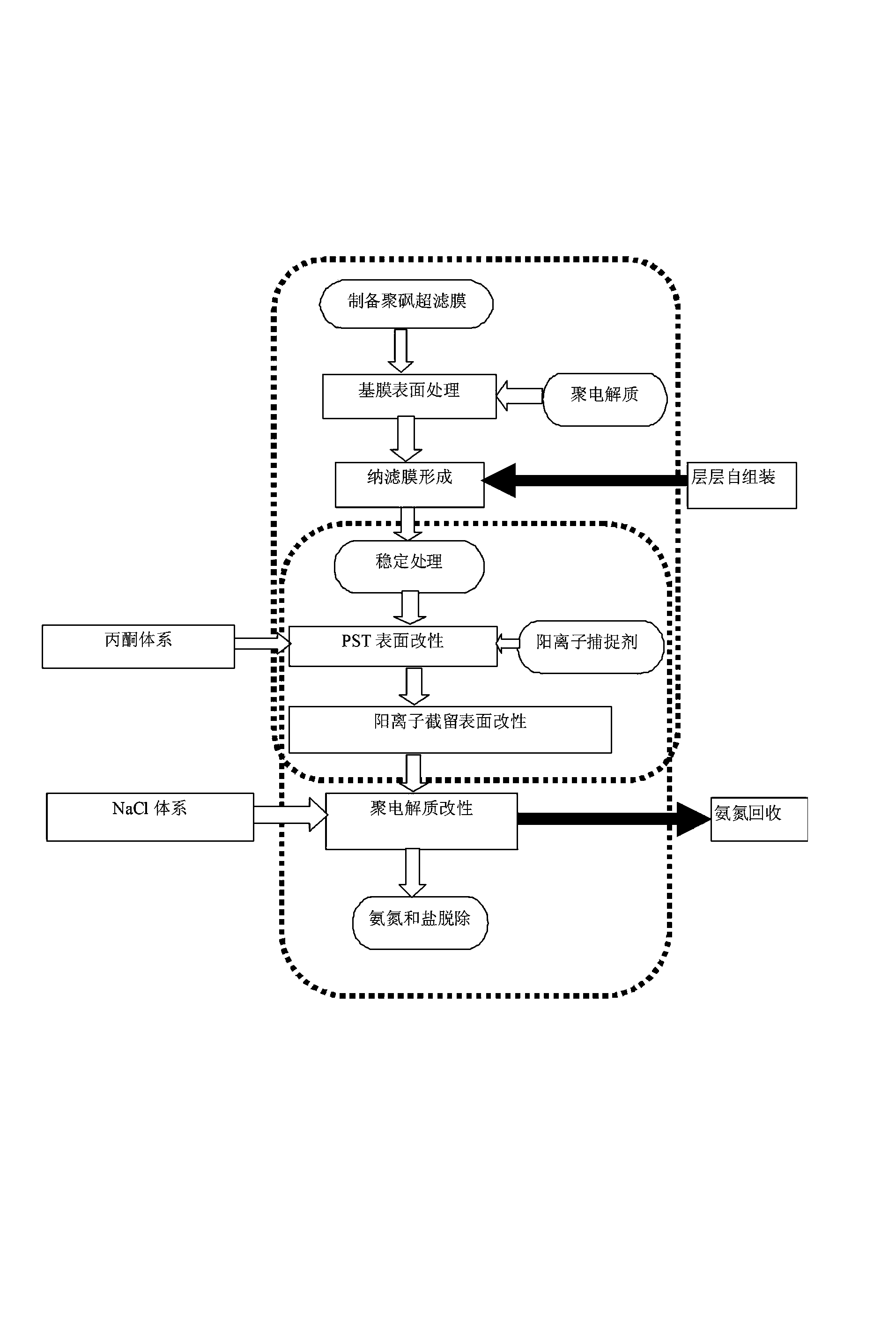

[0020] Using acetone as the dispersant, and then using the polysulfone ultrafiltration membrane prepared by the L-S phase inversion method as the base membrane, the static layer-by-layer self-assembly technology was used to prepare polydiallyldimethylammonium chloride / polyethylene oxide in the sodium chloride system. Sodium styrene sulfonate multi-layer polyelectrolyte nanofiltration membrane, for desalination and recovery of ammonia nitrogen components, using PST surface modification additive at 50°C to modify the surface properties of nanofiltration membrane materials for 24 hours, and can be based on the ion The type, concentration, and number of self-assembled layers adjust the modification strength. In the process of treating trona to prepare and discharge waste liquid, the nanofiltration high-salinity lye wastewater desalination and solvent component recovery proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com