Method for growing Ce<3+> doped lutetium yttrium silicate scintillation crystal

A technology of yttrium lutetium silicate and crystal is applied in the field of pulling Ce3+ doped yttrium lutetium silicate crystal, which can solve the problems of easy cracking, low crystal yield, greatly increased success rate, etc. The effect of yellowing, good crystal quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

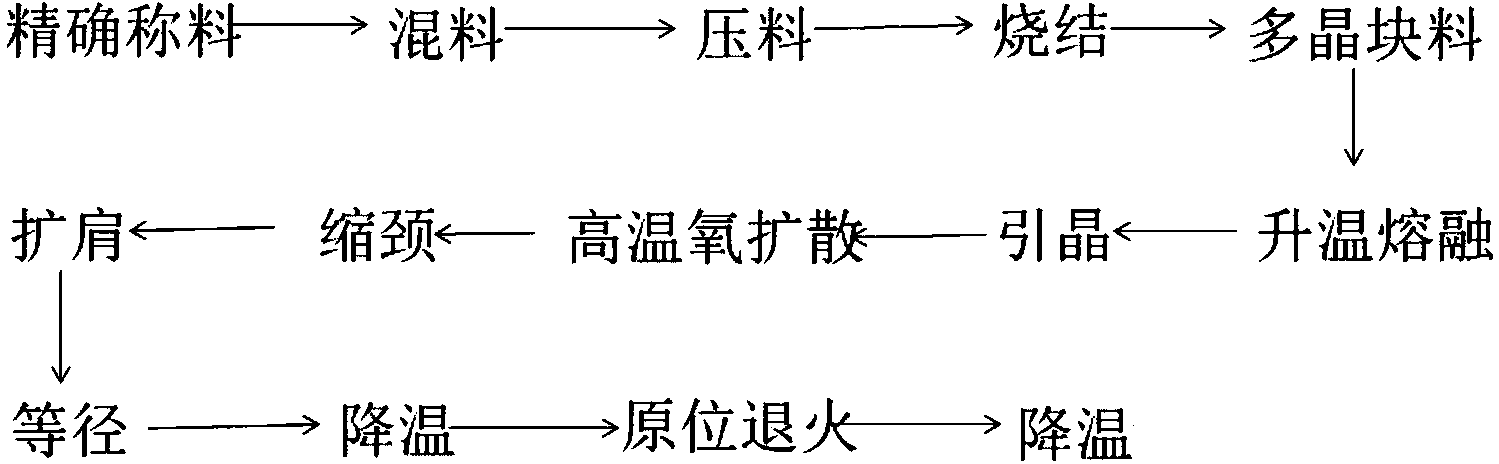

[0028] Example 1.Ce 3+ The growth of doped yttrium lutetium silicate crystals, the specific process is as follows figure 1 Shown:

[0029] (1) Weighing and mixing: according to trivalent Ce 3+ Chemical formula Ce of doped yttrium lutetium silicate single crystal 2x (Lu 1-y Y y ) 2(1-x) SiO 5 , wherein, 0.001≤x≤0.05, 02 O and CO 2 , by oxide (Lu 2 o 3 , Y 2 o 3 , CeO 2 , SiO 2 ) The corresponding molar ratio is accurately weighed, and fully mixed into a uniform powder;

[0030] (2) Pressing and sintering: Press the mixed powder into a cylindrical cake under a pressure of 150Mpa, and sinter at 1300°C for 15 hours to form Ce 3+ Doped yttrium lutetium silicate polycrystalline cake material, in which the cold isostatic pressing machine is used for pressing, and the muffle furnace is used for sintering;

[0031] (3) Heating and melting: Put a crucible that can withstand high temperature and will not deteriorate rapidly in an oxygen environment, such as an iridium cru...

Embodiment 2

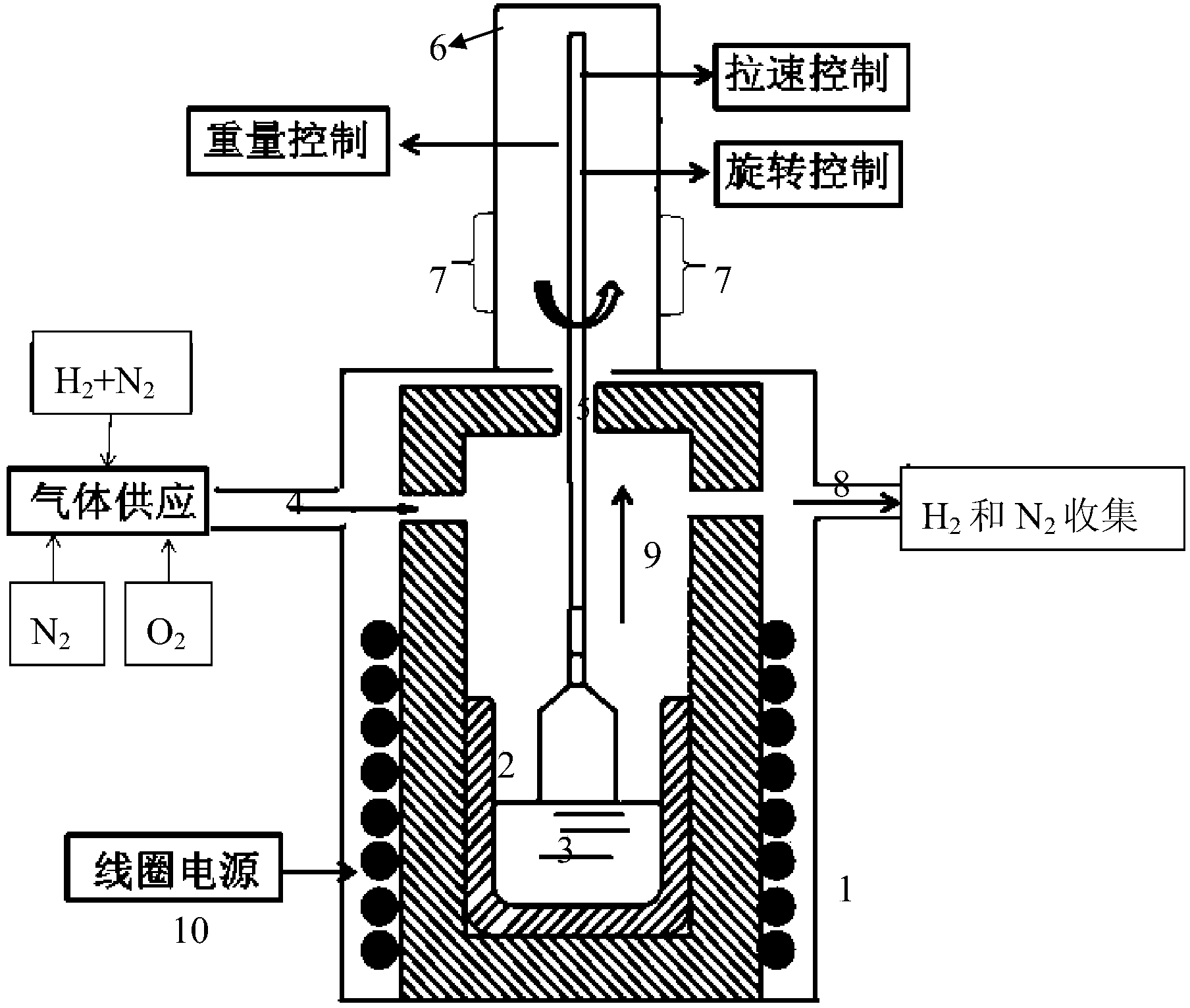

[0038] Growth Ce described in Example 1 3+ The growth furnace used for doping yttrium lutetium silicate crystals is an improved crystal furnace. The improvement of the crystal furnace was previously submitted in the application titled "A Straightening White Gem Single Crystal Growth Furnace Structure Improvement and Method" (Application No. 201210099937. On the basis of X), the main improvements are the following two aspects:

[0039] ① A gas outlet 8 is added to the heat insulator. The position of the gas outlet 8 on the heat insulator 1 is symmetrical to the left opening 4 of the gas inlet. It is mainly used for in-situ annealing after crystal growth. 2 and N 2 The mixed gas is discharged to H 2 and N 2 in the collection box;

[0040] ② On the middle opening 5 directly above the heat insulator, place a sealing cover 6 and two small doors 7 are arranged on both sides of the sealing cover, during the crystal growth process O 2 and N 2 The mixed gas flows out from here (c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com