Method for detecting components of elements in coated titanium dioxide

A technology of element composition and titanium dioxide, which is applied in the field of detection and analysis of coated titanium dioxide products, can solve the problems of interfering element composition content determination, absence or lack, etc., achieve the effect of reducing types and dosage, improving analysis speed, and shortening the inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] XRF Calibration Sample Preparation Procedure

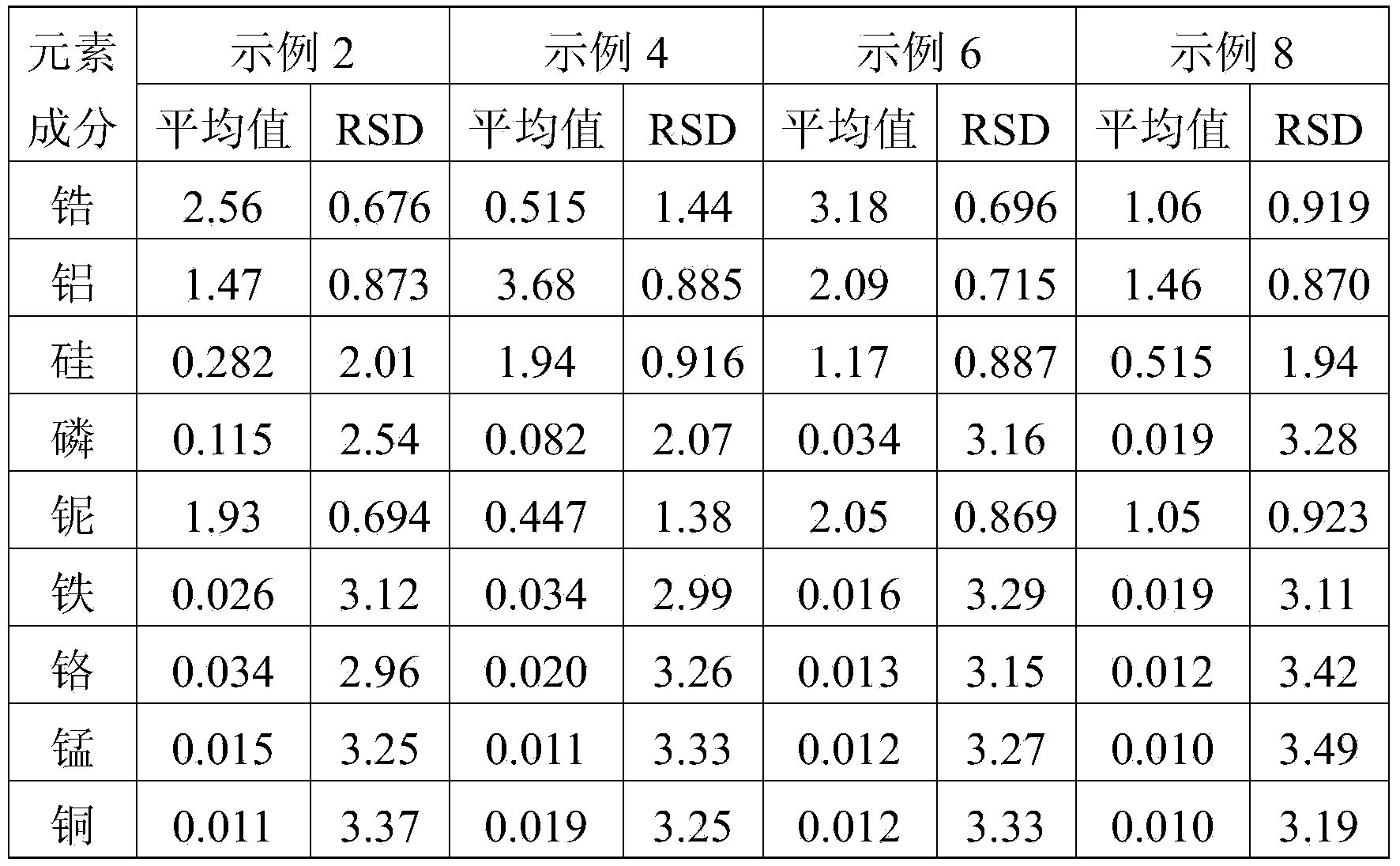

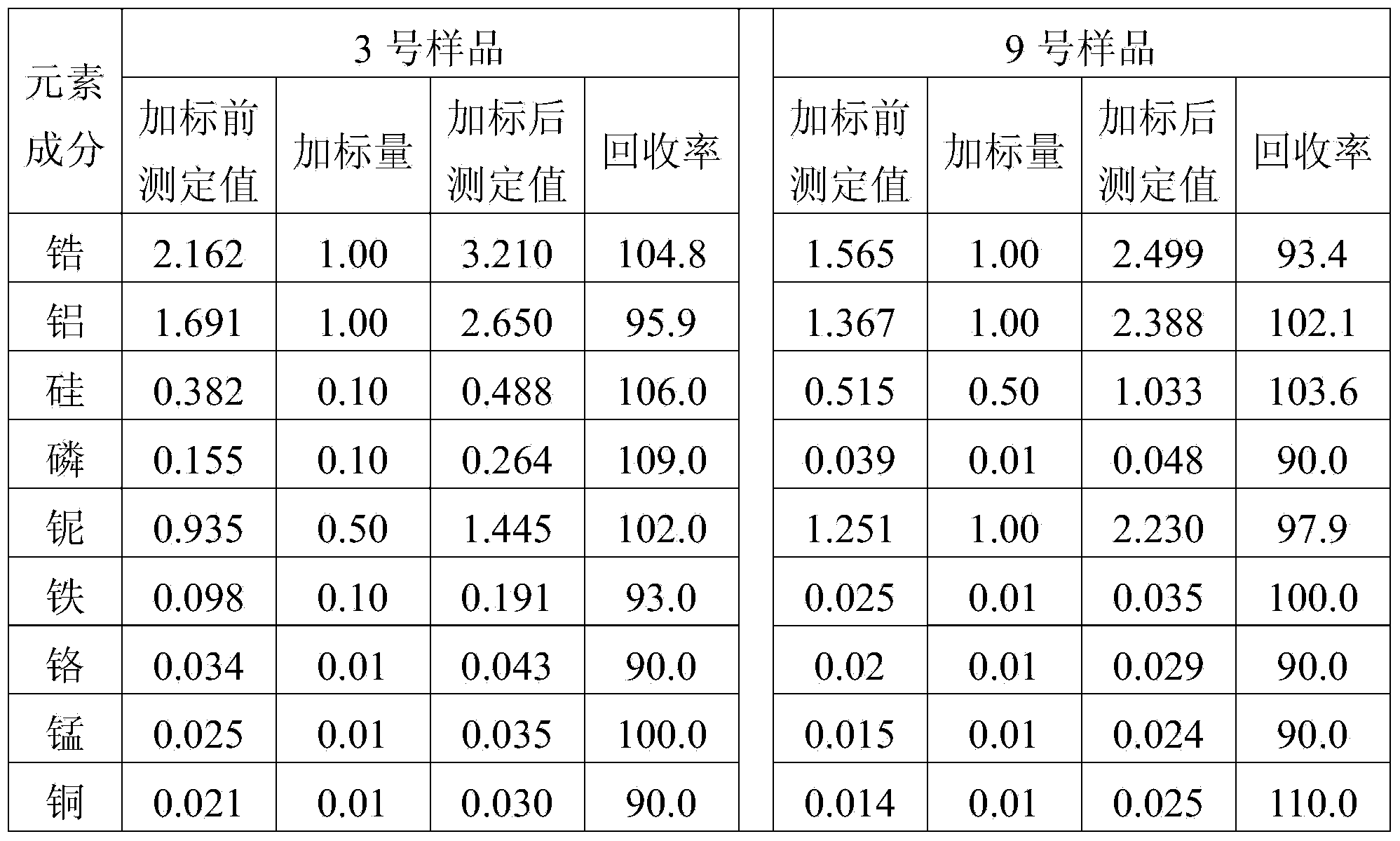

[0019] Use microwave digestion-ICP-OES method to determine the percentage of elemental composition of coated titanium dioxide products of different grades or standards actually produced under the same process conditions as the sample to be tested, and select 3-7 uniformity Good stability, element composition content can constitute a concentration gradient and its range covers a series of coated titanium dioxide samples of different grades or standards, and then repeat microwave digestion and ICP- For OES measurement, the statistical average value of the measurement results is used as the standard value of the elemental composition content, and then the coated titanium dioxide product selected and checked by this value is used as the XRF calibration sample.

example 1

[0036] Prepare XRF calibration samples and draw calibration curves

[0037] 1. Microwave digestion of coated titanium dioxide samples:

[0038]Weigh 0.2500 g of the coated titanium dioxide sample initially screened by XRF powder pressing semi-quantitative method into a microwave digestion tank, rinse the tank wall with 15 mL of water and disperse the sample, add 4 mL (1+1) sulfuric acid, 8 mL nitric acid and 2 mL hydrogen in sequence For hydrofluoric acid, immediately seal the container and carry out microwave digestion; the control conditions of microwave digestion are set as follows: adopt the ramp heating method, control the pressure in the container to be less than 800psi, first raise the temperature of the material in the container to 200°C for 10 minutes and keep it warm for 15 minutes, and then use 5 minutes to heat up to 230°C and keep warm for 5min. After the solution in the tank is cooled to room temperature, it is directly diluted with water and fixed in a 100mL pl...

example 2

[0051] First, the coated titanium dioxide sample to be tested (sample No. 2) was sieved through a 74 μm standard sieve, dried at (110±5)°C for 1 hour and cooled to room temperature, and 2 g of the sample powder was weighed and directly placed in a diameter In a mold such as a 40mm aluminum ring, spread it evenly and press it with a little pressure, then fill the entire mold with boric acid, apply a pressure of 15 tons on the press for 5 seconds, and press it into a sheet-shaped XRF calibration sample or to be tested Coated titanium dioxide samples.

[0052] Then, using the XRF calibration sample prepared in Example 1 and the drawn XRF calibration curve, measure the x-fluorescence intensity values of the corresponding elemental components in the pressed sample of sample No. 2 and calculate the percentage content of the elemental components in the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com