Lithium-ion battery, negative electrode sheet and preparation method thereof

A technology of lithium ion battery and negative pole piece, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, negative electrodes, etc., can solve the problems of loose structure, increased local thickness, easy collapse, etc. Cyclic performance, the effect of reducing swelling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

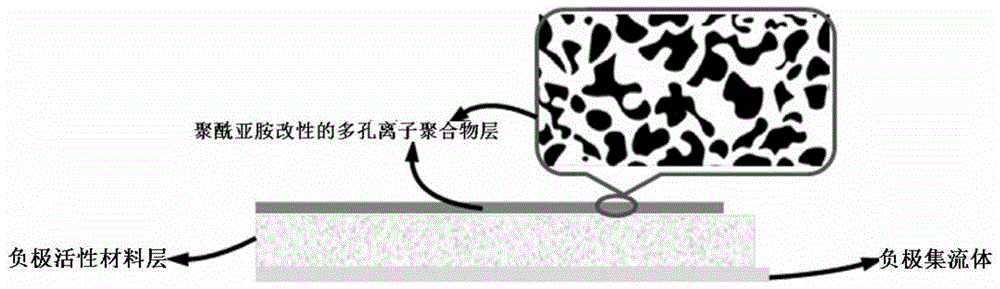

[0029] According to the second aspect of the present invention, the preparation method of the negative electrode sheet of the lithium ion battery includes the steps of: (1) fully mixing the negative electrode active material, the negative electrode conductive agent, the negative electrode binder and the negative electrode dispersant according to an appropriate proportion to obtain the negative electrode active material Slurry, the negative electrode active material slurry is coated on the negative electrode current collector, and the negative electrode active material layer is obtained after drying; (2) the porous ionic polymer and the polyimide monomer are dispersed in an organic solvent, and the Stir to obtain the composite slurry; (3) Coat the composite slurry on the surface of the negative electrode active material layer, after drying, heat and keep warm under vacuum or under the protection of protective gas to polymerize the polyimide monomer, cool After that, a polyimide-...

Embodiment 1

[0047] A negative electrode sheet preparation

[0048] (1) Fully mix the negative electrode active material natural graphite, the conductive agent conductive carbon black, the binder styrene-butadiene rubber and the dispersant sodium carboxymethyl cellulose according to the mass ratio of 96:1:2:1 to obtain the negative electrode active material slurry , coating the negative electrode active material slurry on a negative electrode current collector copper foil with a thickness of 12 μm, and drying at 100° C. for 5 hours to obtain a negative electrode active material layer with a thickness of 90 μm.

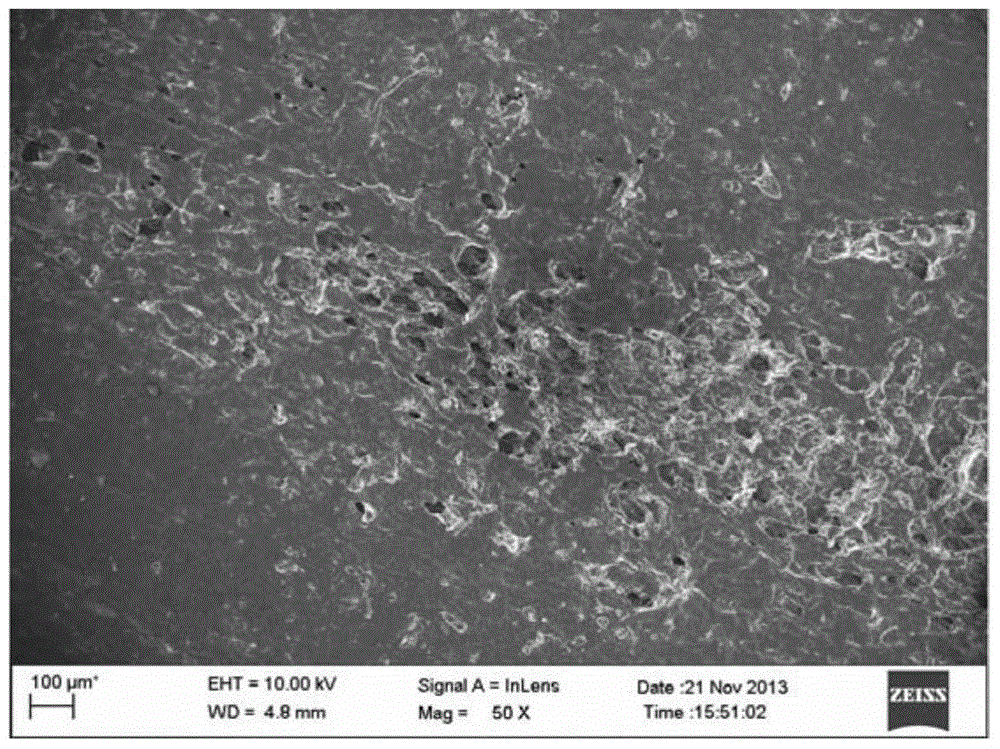

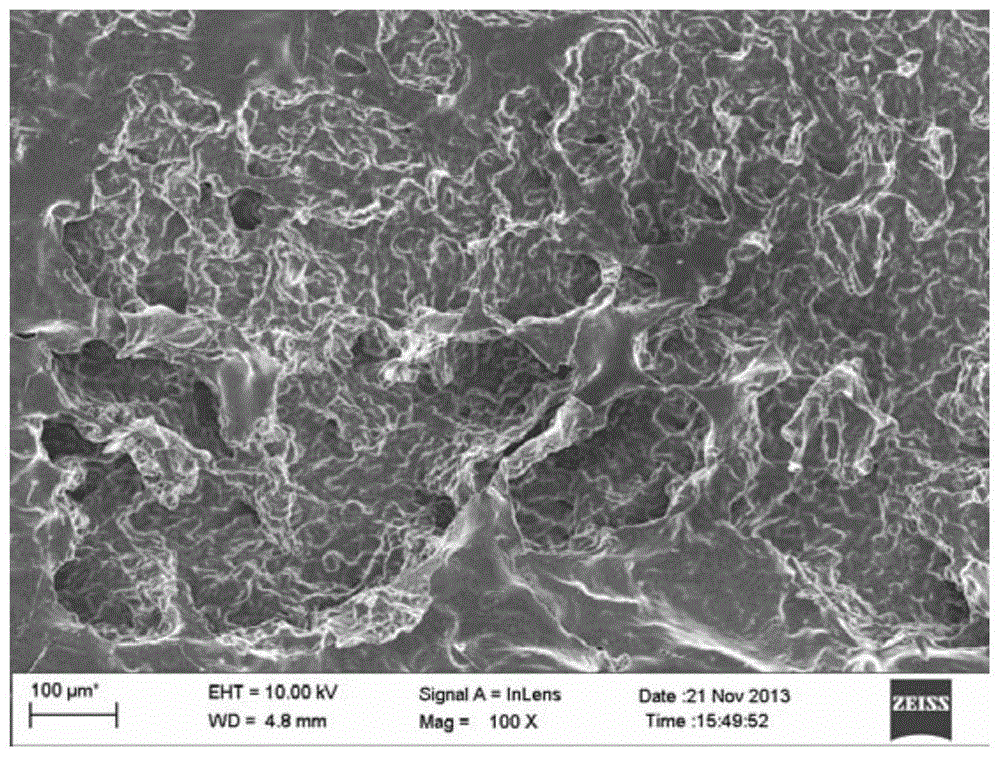

[0049] (2) Dissolve porous polyvinylidene fluoride (PVDF) with a porosity of 41.2% in advance with N-methylpyrrolidone (NMP), wherein the mass of porous polyvinylidene fluoride (PVDF) accounts for 7% of the total mass of the solution, and then Add the polyimide monomer accounting for 1% by mass of the solution, wherein the polyimide monomer is a premix of monomer A and monomer B an...

Embodiment 2

[0056] A negative electrode sheet preparation

[0057] (1) Fully mix the negative electrode active material natural graphite, the conductive agent conductive carbon black, the binder styrene-butadiene rubber and the dispersant sodium carboxymethyl cellulose according to the mass ratio of 96:1:2:1 to obtain the negative electrode active material slurry , coating the negative electrode active material slurry on a negative electrode current collector copper foil with a thickness of 12 μm, and drying at 100° C. for 5 hours to obtain a negative electrode active material layer with a thickness of 90 μm.

[0058] (2) Dissolve porous polyvinylidene fluoride (PVDF) with a porosity of 52.2% in advance with N-methylpyrrolidone (NMP), wherein the mass of porous polyvinylidene fluoride (PVDF) accounts for 7% of the total mass of the solution, and then Add the polyimide monomer accounting for 2% by mass of the solution, wherein the polyimide monomer is a premix of monomer A and monomer B an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com