Ornithine aspartate effervescent tablets and preparing process thereof

A technology of ornithine aspartic acid and effervescent tablets, which is applied to medical preparations containing active ingredients, drug delivery, digestive system, etc., to achieve high bioavailability, rapid onset, and fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

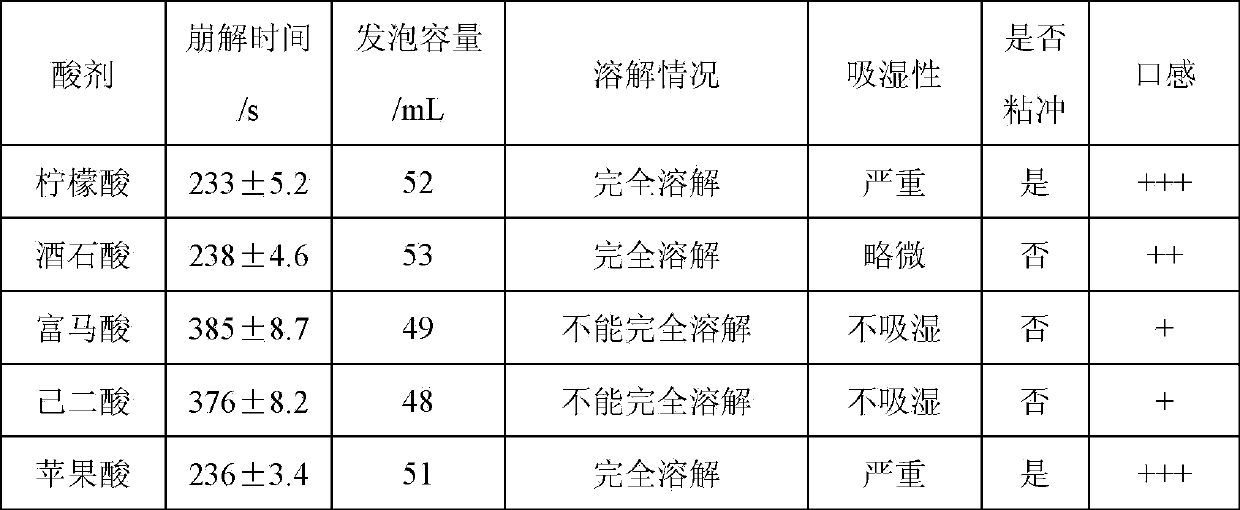

[0032] Embodiment 1 uses different organic acids to prepare ornithine-aspartic acid effervescent tablets

[0033] prescription

[0034] Citric acid (288 g), tartaric acid (338 g), fumaric acid (261 g), adipic acid (329 g) and malic acid (302 g) were used as acid agents, respectively. Other ingredients in the prescription are as follows:

[0035] Ornithine Aspartate

1000g

Povidone K30

45g

210g

stevia

0.75

0.75

[0036] polyethylene glycol 6000

150

production

1000 pieces

[0037] method

[0038] Using polyethylene glycol encapsulation-wet granulation process:

[0039] 1) Take polyethylene glycol 6000 and mix evenly with sodium bicarbonate, heat in a water bath at 70°C for 20 minutes to melt, then pulverize after cooling, and pass through an 80-mesh sieve.

[0040] 2) Take ornithine aspartate, add tartaric acid, mix evenly, use povidone K30 ethanol...

Embodiment 2-5

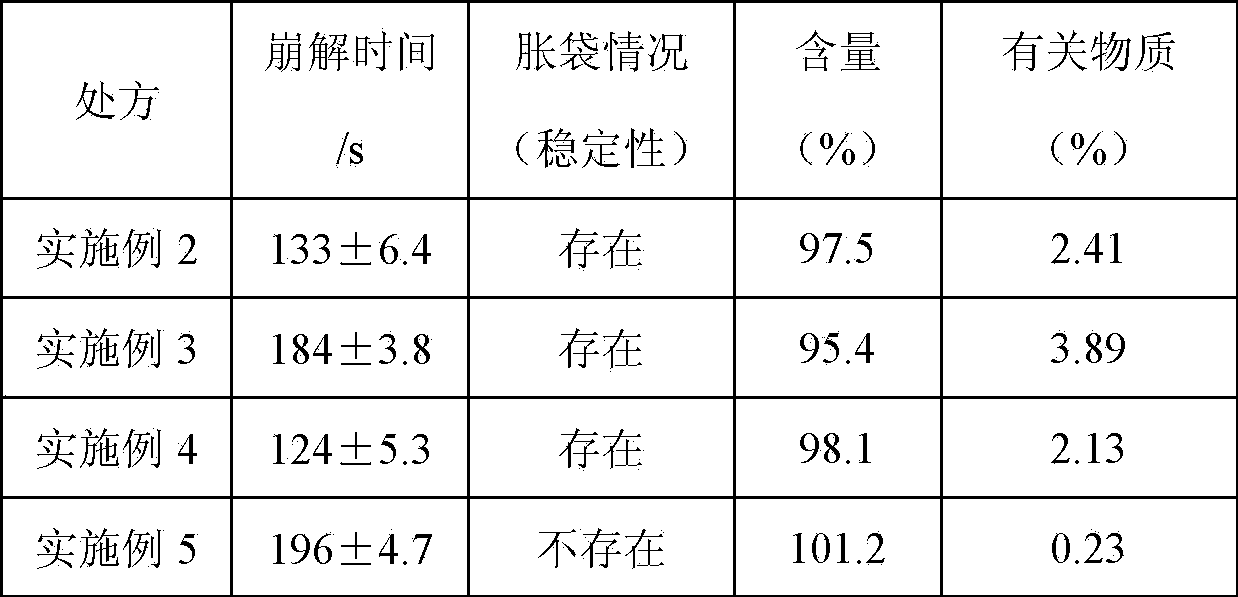

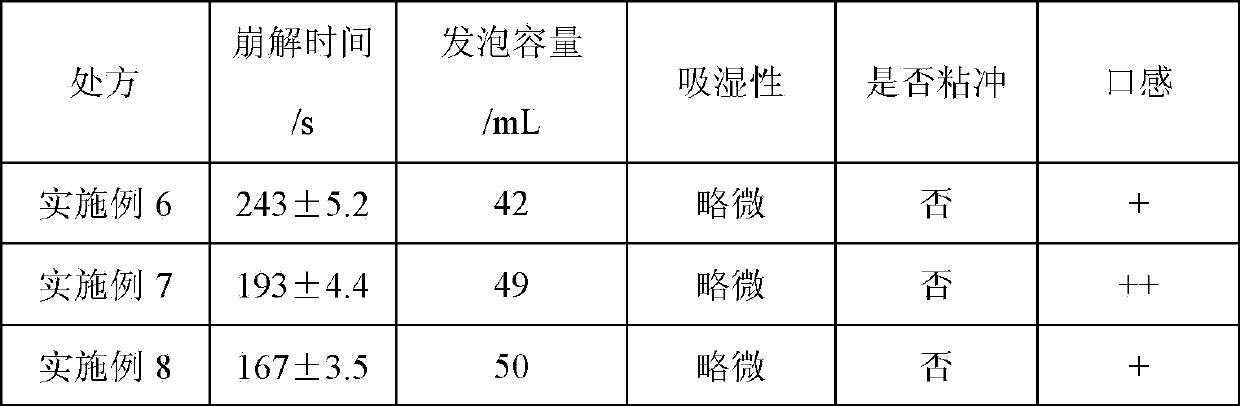

[0047] Embodiment 2-5: the screening of preparation process

Embodiment 2

[0048] Embodiment 2 dry granulation process

[0049] prescription

[0050] Ornithine Aspartate

1000g

Copovidone S630

45g

338g

210g

stevia

0.75

0.75

polyethylene glycol 6000

30

production

1000 pieces

[0051] method

[0052] Using dry granulation process:

[0053] 1) Take ornithine aspartate, copovidone S630, tartaric acid, sodium bicarbonate, and mix well.

[0054] 2) Rolling into large pieces and crushing to obtain granules.

[0055] 3) Add stevioside, orange essence and polyethylene glycol 6000, mix well, and press into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com