Carbon offset method for methane synthesis gas prepared from dry distillation gas

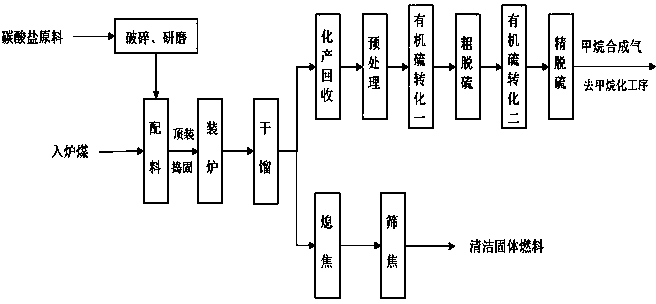

A methane synthesis gas and dry distillation gas technology, which is applied in combustible gas purification, liquid scrubbing gas purification, combustible gas purification/transformation, etc., can solve the problems of difficult coal dry distillation enterprise promotion, complicated process, large one-time investment, etc., and achieve improvement The effect of environmental quality, simple process and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] According to the above-mentioned specific embodiment of the present invention, a kind of method for replenishing carbon by dry distillation coal gas to methane synthesis gas is specifically implemented, and in the method for replenishing carbon described in it:

[0088] Limestone ore composition (wt%): CaO 54.3%, burning loss rate 42.7%, impurity 3.0%.

[0089] The furnace coal is composed of 30% lean coal, 35% 1 / 3 coking coal, 20% fat coal and 15% main coking coal; its quality index (wt%): V adf 30.0%, A d 13.5%, FC d 60.6%, S t,d 0.67%, cohesion index G=74, fineness (≤3mm)=73.6%.

[0090] The coal into the furnace was tested in a 40kg small coke oven (the furnace charge was isolated from the air and continuously heated for 24 hours, the temperature of the center of the furnace charge reached 1100°C before being released from the furnace, and it was cooled to room temperature after coke quenching): the gas production rate of the furnace charge was 353.4 Nm 3 / t;...

Embodiment 2

[0100] Dolomite ore composition (wt%): CaO 30.4%, MgO 21.7%, burning loss rate 47.4%, impurity 0.46%.

[0101] The furnace coal is composed of 30% lean coal, 35% 1 / 3 coking coal, 20% fat coal and 15% main coking coal; its quality index (wt%): V adf 30.0%, A d 13.5%, FC d 60.6%, S t,d 0.67%, cohesion index G=74, fineness (≤3mm)=73.6%.

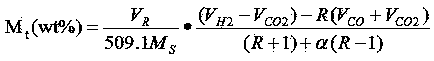

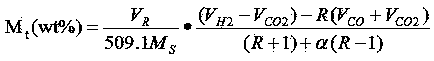

[0102] The coal into the furnace was tested in a 40kg small coke oven (the charge was continuously heated for 20 hours in isolation from the air, and the center temperature of the charge reached 1050°C before it was released from the furnace, and it was cooled to room temperature after coke quenching): the gas production rate of the charge into the furnace was 353.4 Nm 3 / t; In dry distillation gas before adding carbonate carbon replenishing raw materials: H 2 57.5%, CH 4 24.5%, CO7.5%, CO 2 2.8%, the rest is N 2 、C m h n , O 2 Wait. CO 2 The conversion ratio is calculated as 0.55, and the hydrogen-to-carbon ratio is calculated as 3...

Embodiment 3

[0112] Siderite composition (wt%): FeO 52.7%, burning loss rate 26.3%, impurity 21.0%.

[0113] The furnace coal is composed of 30% lean coal, 35% 1 / 3 coking coal, 20% fat coal and 15% main coking coal; its quality index (wt%): V adf 30.0%, A d 13.5%, FC d 60.6%, S t,d 0.67%, cohesion index G=74, fineness (≤3mm)=73.6%.

[0114] The coal into the furnace was tested in a 40kg small coke oven (the charge was continuously heated for 15 hours in isolation from the air, the center temperature of the charge reached 950°C before being released from the furnace, and it was cooled to normal temperature after coke quenching): the gas production rate of the charge into the furnace was 353.4 Nm 3 / t; In dry distillation gas before adding carbonate carbon replenishing raw materials: H 2 54.5%, CH 4 25.5%, CO10.7%, CO 2 3.7%, the rest is N 2 、C m h n , O 2 Wait. CO 2 The conversion ratio is calculated as 0.55, and the hydrogen-to-carbon ratio is calculated as 3.10. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com