Ag nano-material having ultraviolet band with hybrid quadrupole and preparation method thereof

A technology of ultraviolet band and nanomaterials, applied in nanotechnology, nanotechnology, nano-optics, etc., can solve problems such as unfavorable application, difficult preparation process, and increased metal absorption loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing Ag nanomaterials with hybrid quadrupoles in the ultraviolet band, comprising the following steps:

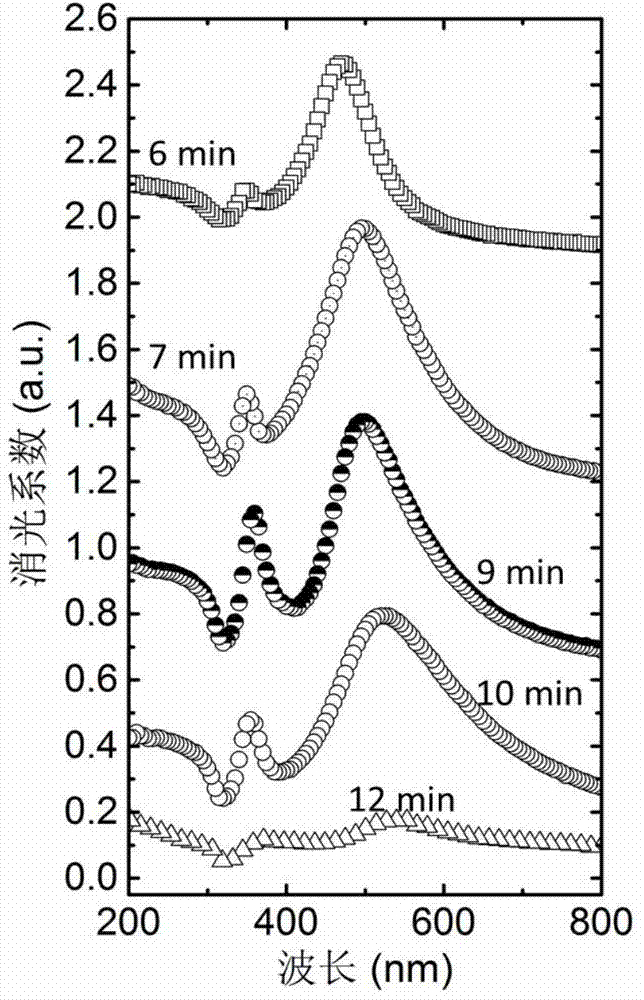

[0023] Step 1: using metal sputtering equipment on the sapphire substrate to prepare an Ag nanoparticle film by controlling the sputtering current and sputtering time, the sputtering current is 2mA-14mA, and the sputtering time is 1-12min;

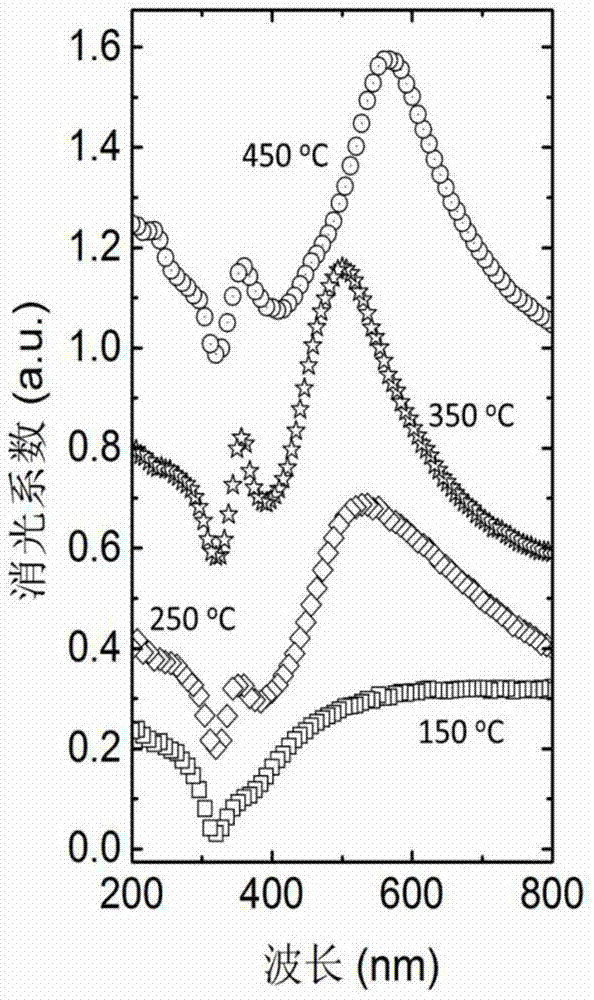

[0024] Step 2: In an inert atmosphere, the Ag nanoparticle film obtained in Step 1 is annealed at a temperature of 250-450° C. to obtain Ag nanomaterials with hybrid quadrupoles in the ultraviolet band.

[0025] In the present invention, there are mainly two factors affecting the appearance of the quadrupole resonance peak in the ultraviolet band: the size of the nanoparticles in the Ag nanocluster and the distance between the adjacent nanoparticles. From a macro point of view, its resonance strength can be determined by the density of Ag nanoclusters, that is, the sputtering current, sput...

Embodiment 1

[0031] On the sapphire substrate, the Ag nanoparticle film was prepared by precisely controlling the sputtering current to 2 mA and the sputtering time to 6 minutes using metal sputtering equipment. 2 In the atmosphere, the above-mentioned Ag nanoparticle film is annealed at a temperature of 450° C. for 3 minutes, that is, an Ag nanomaterial with hybrid quadrupoles in the ultraviolet band.

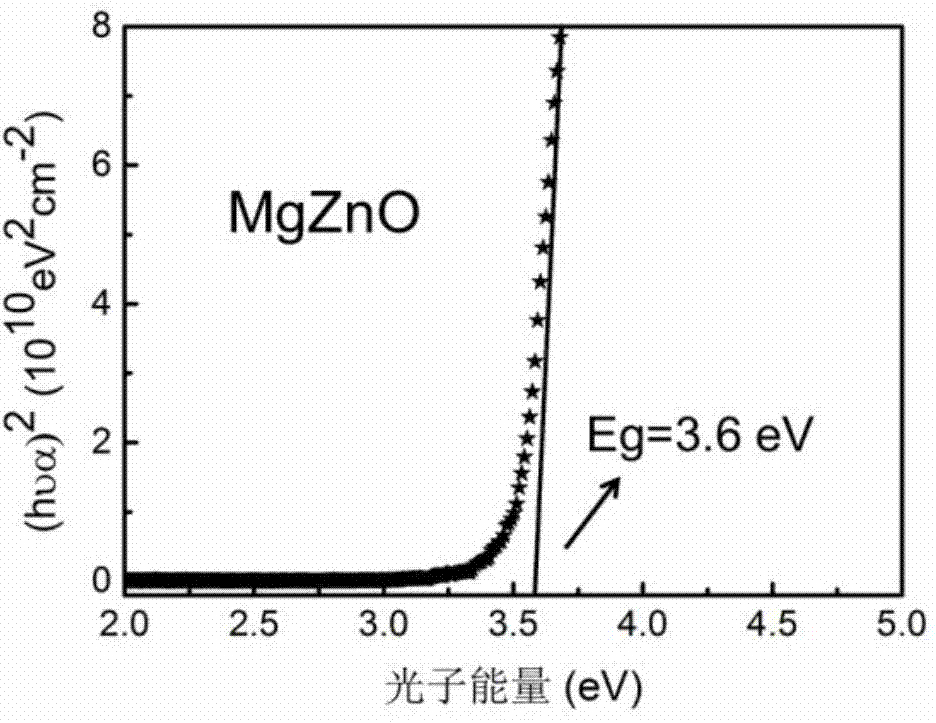

[0032] On the MOCVD equipment, C-plane sapphire and Ag nanoclusters prepared by the above method are used as the substrate, magnesium dicene is used as the magnesium source, diethyl zinc is used as the zinc source, and the carrier gas is 99.9999% high-purity nitrogen, as follows Process conditions for the preparation of single hexagonal phase MgZnO thin films: the substrate temperature is 450 °C, and the vacuum degree of the growth chamber is 2×10 4 Pa, the oxygen flow rate is 550ml / min (3×10 5 Pa), through the flow control, the molar concentration of Zn and Mg in the growth chamber can b...

Embodiment 2

[0034] On the sapphire substrate, the Ag nanoparticle film was prepared by precisely controlling the sputtering current to 2 mA and the sputtering time to 7 minutes using metal sputtering equipment. 2 In the atmosphere, the above-mentioned Ag nanoparticle film is annealed at a temperature of 450° C. for 3 minutes, that is, an Ag nanomaterial with hybrid quadrupoles in the ultraviolet band.

[0035] On MOCVD equipment, C-plane sapphire and Ag nanoclusters prepared by the above method are used as the substrate, magnesium dicene is used as the magnesium source, diethyl zinc is used as the zinc source, and the carrier gas is 99.9999% high-purity nitrogen, as follows Process conditions for the preparation of single hexagonal phase MgZnO thin films: the substrate temperature is 450 °C, and the vacuum degree of the growth chamber is 2×10 4 Pa, the oxygen flow rate is 550ml / min (3×10 5 Pa), through the flow control, the molar concentration of Zn and Mg in the growth chamber can be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com