Anatase TiO2 nanometer tree array and application of anatase TiO2 nanometer tree array to solar cell preparation

An anatase and nano-technology, applied in the field of solar cells, can solve the problems of limited light energy conversion efficiency, high production cost, and insufficient specific surface area, so as to improve reaction efficiency and preparation cost, and require less reaction equipment and reaction equipment demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

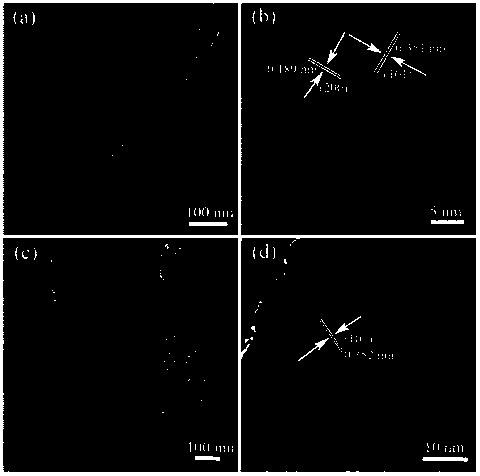

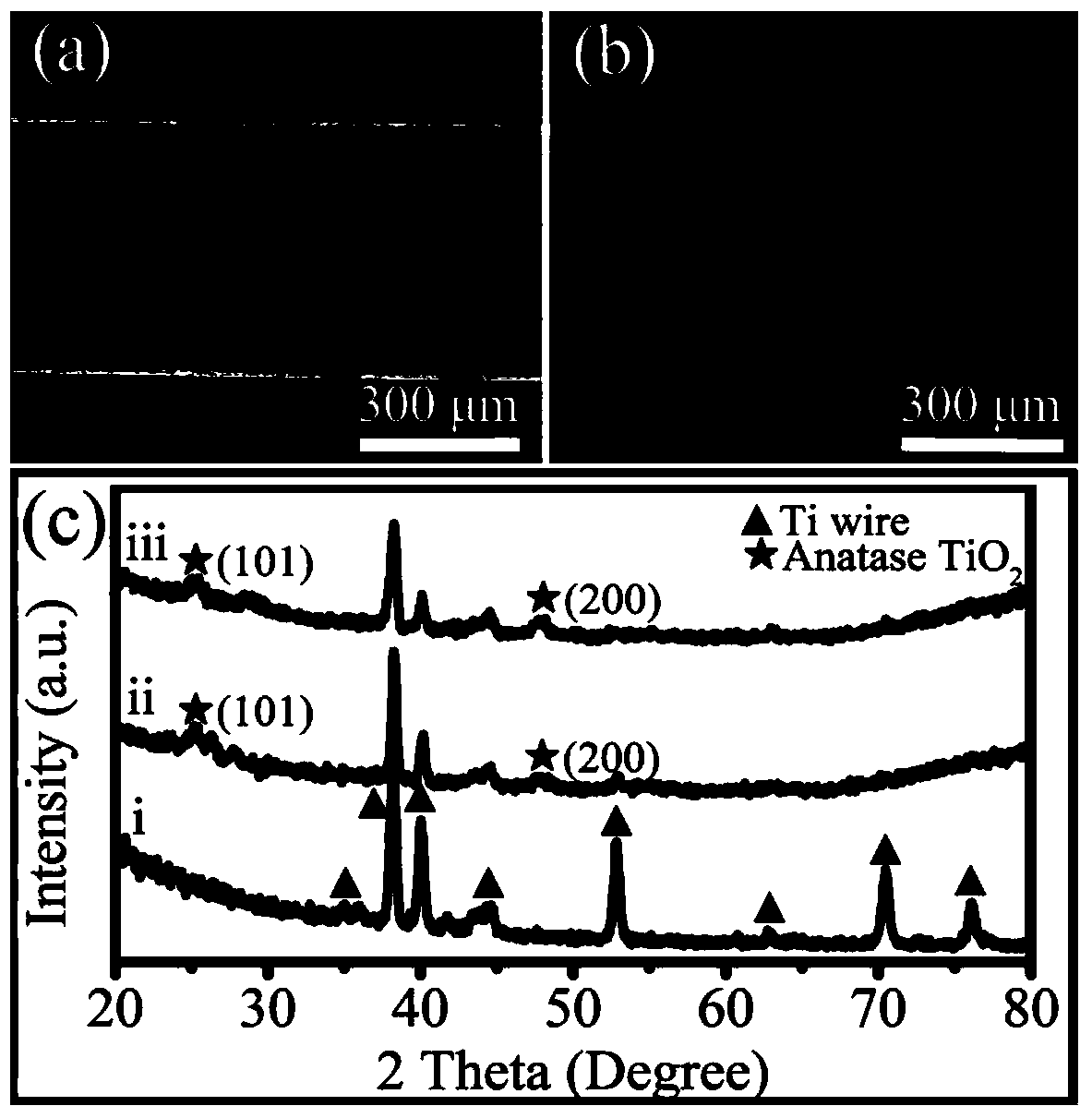

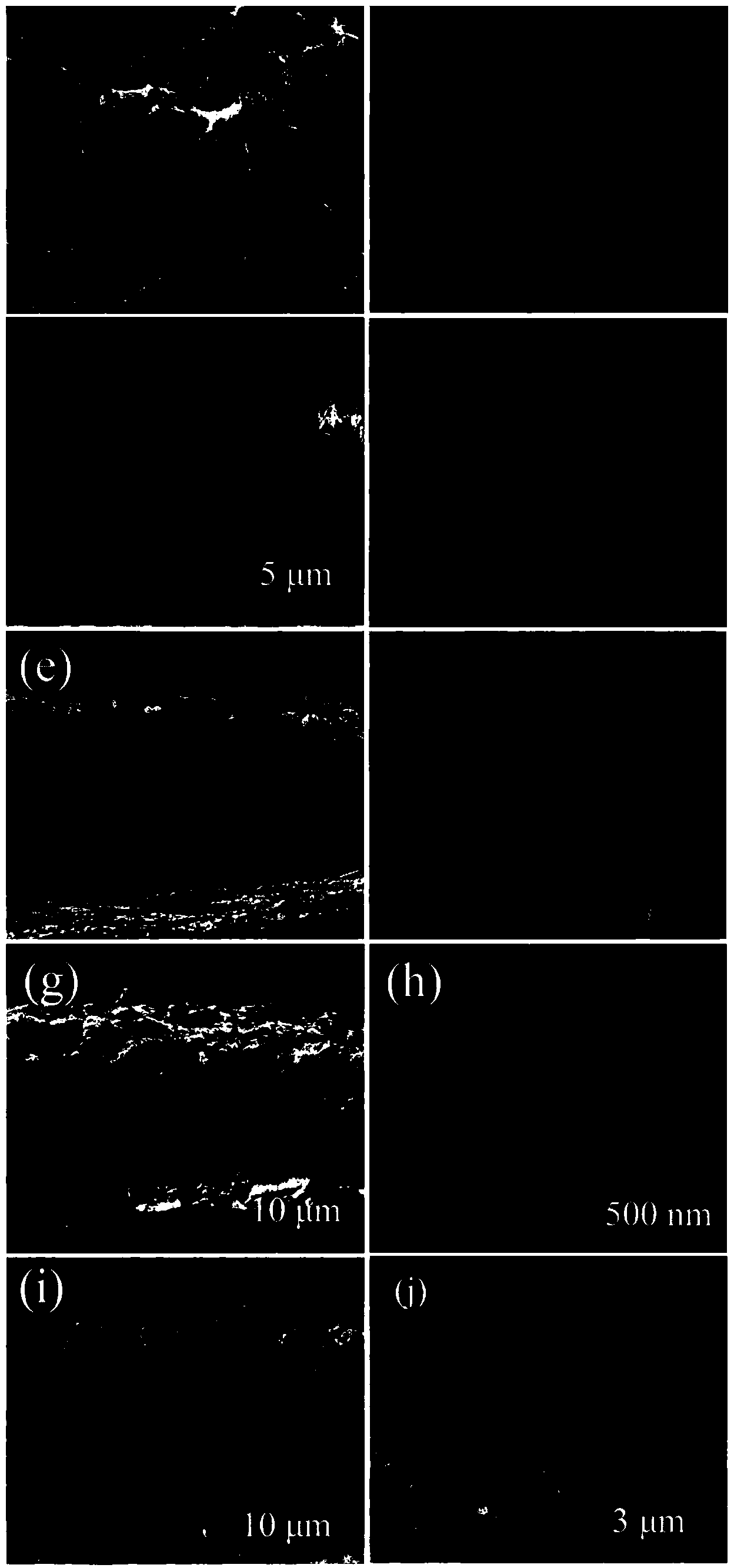

Embodiment 1

[0049] Polish the titanium wire with sandpaper, wash it with detergent and water, and then ultrasonically clean it with deionized water, acetone and ethanol; after the titanium wire is dried, immerse it in (NH 4 ) 2 TiF 6 and H 3 BO 3 In the mixed solution of the titanium wire, place it at room temperature for half an hour to form TiO on the surface of the titanium wire 2 Nanoparticle seed layer, (NH 4 ) 2 TiF 6 and H 3 BO 3 The molar concentrations are 0.10M and 0.20M respectively; add 1.240g potassium titanium oxide oxalate dihydrate into 50ml diethylene glycol solution and stir for 45min, then add 20ml water and stir evenly for 15min to obtain a reaction solution, transfer it to an autoclave, and then Multiple roots with TiO 2 The titanium wire of the nanoparticle seed layer is immersed in the reaction solution, and the reaction is carried out in a closed autoclave. The reaction temperature is 180 ° C, and the reaction time is 12 hours; (5) After the reaction is co...

Embodiment 2

[0052] Polish the titanium wire with sandpaper, wash it with detergent and water, and then ultrasonically clean it with deionized water, acetone and ethanol; after the titanium wire is dried, immerse it in (NH 4 ) 2 TiF 6 and H 3 BO 3 In the mixed solution of the titanium wire, place it at room temperature for half an hour to form TiO on the surface of the titanium wire 2 Nanoparticle seed layer, (NH 4 ) 2 TiF 6 and H 3 BO 3 The molar concentrations were 0.10M and 0.20M respectively; 1.240g potassium titanium oxide oxalate dihydrate was added to 60ml diethylene glycol solution and stirred for 45min, then 20ml water was added and stirred evenly for 15min to obtain a reaction solution, which was transferred to an autoclave, and then Multiple roots with TiO 2 The titanium wire of the nanoparticle seed layer is immersed in the reaction solution, and the reaction is carried out in a closed autoclave. The reaction temperature is 160 ° C, and the reaction time is 3 hours; (5...

Embodiment 3

[0055] Polish the titanium wire with sandpaper, wash it with detergent and water, and then ultrasonically clean it with deionized water, acetone and ethanol; after the titanium wire is dried, immerse it in (NH 4 ) 2 TiF 6 and H 3 BO 3 In the mixed solution of the titanium wire, place it at room temperature for half an hour to form TiO on the surface of the titanium wire 2 Nanoparticle seed layer, (NH 4 ) 2 TiF 6 and H 3 BO 3 The molar concentrations were 0.15M and 0.20M respectively; 1.240g potassium titanium oxide oxalate dihydrate was added to 50ml diethylene glycol solution and stirred for 45min, then 20ml water was added and stirred evenly for 15min to obtain a reaction solution, which was transferred to an autoclave, and then Multiple roots with TiO 2 The titanium wire of the nanoparticle seed layer is immersed in the reaction solution, and the reaction is carried out in a closed autoclave. The reaction temperature is 200 ° C, and the reaction time is 6 hours; (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com