Elemental selenium and sugar compound and preparation method thereof

A technology of elemental selenium and complexes, applied in the field of food additives, can solve the problems of difficult dehydration, difficult dissolution, high energy consumption, etc., and achieve the effects of simple and stable production process, difficult dissolution, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

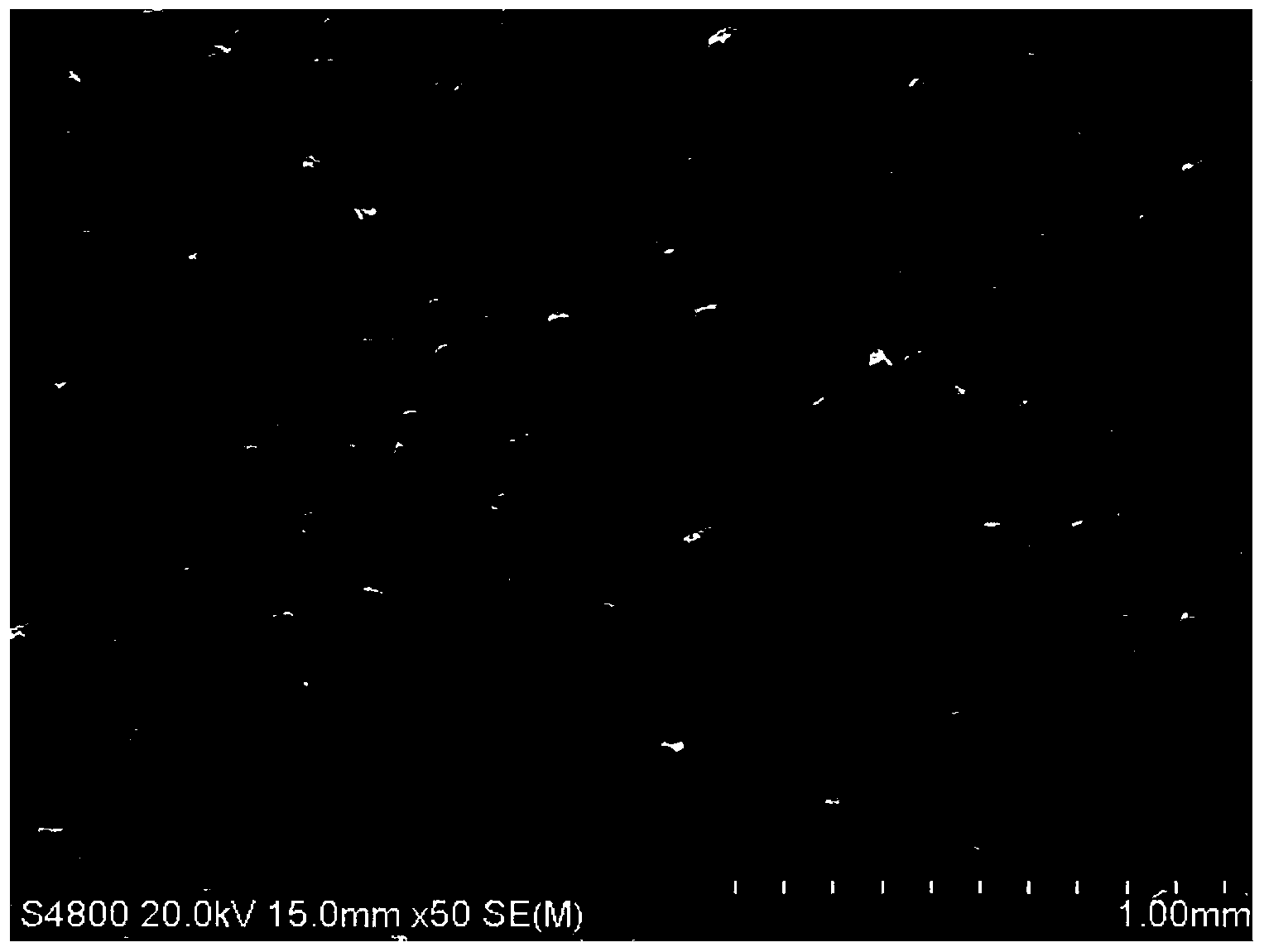

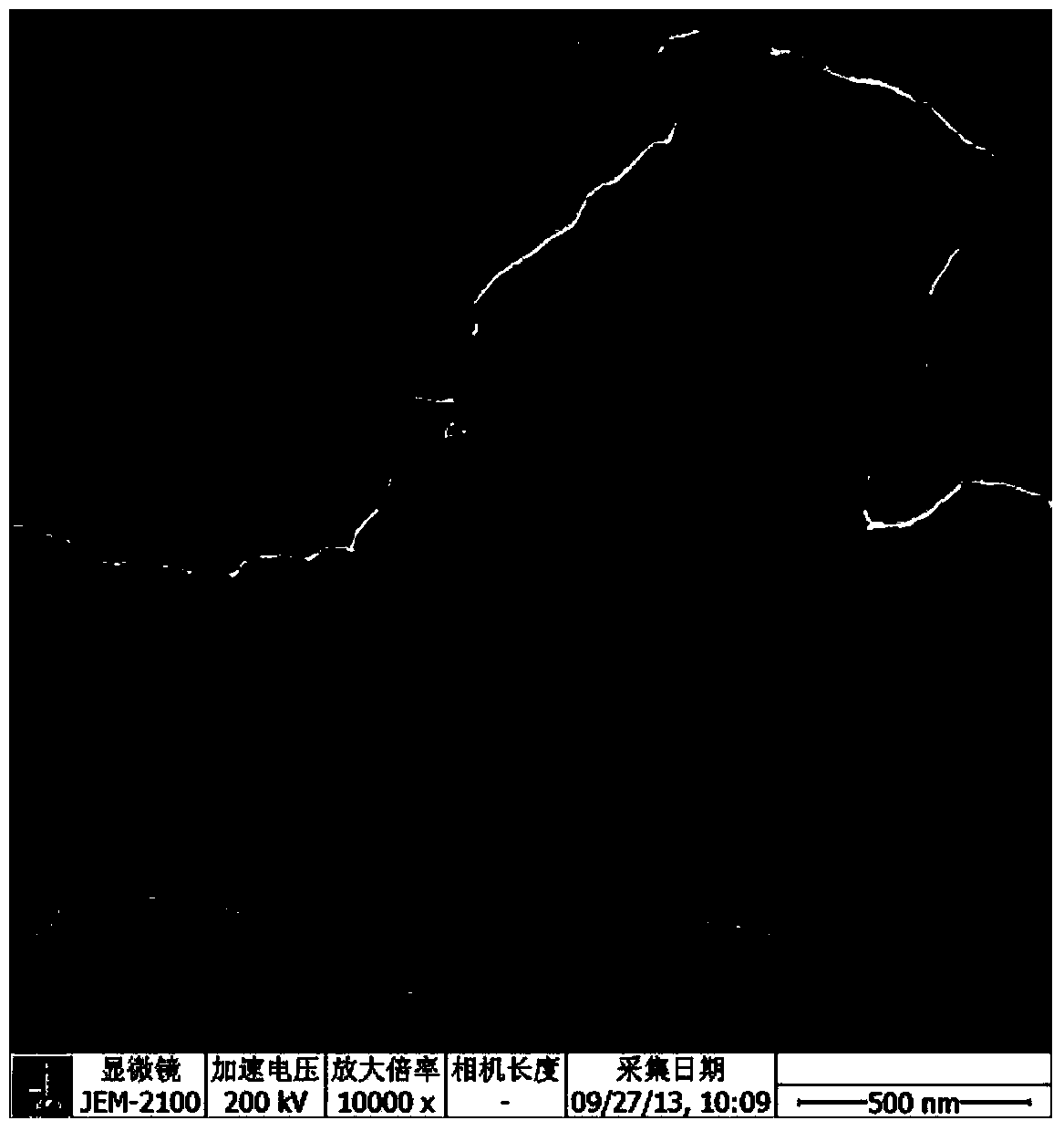

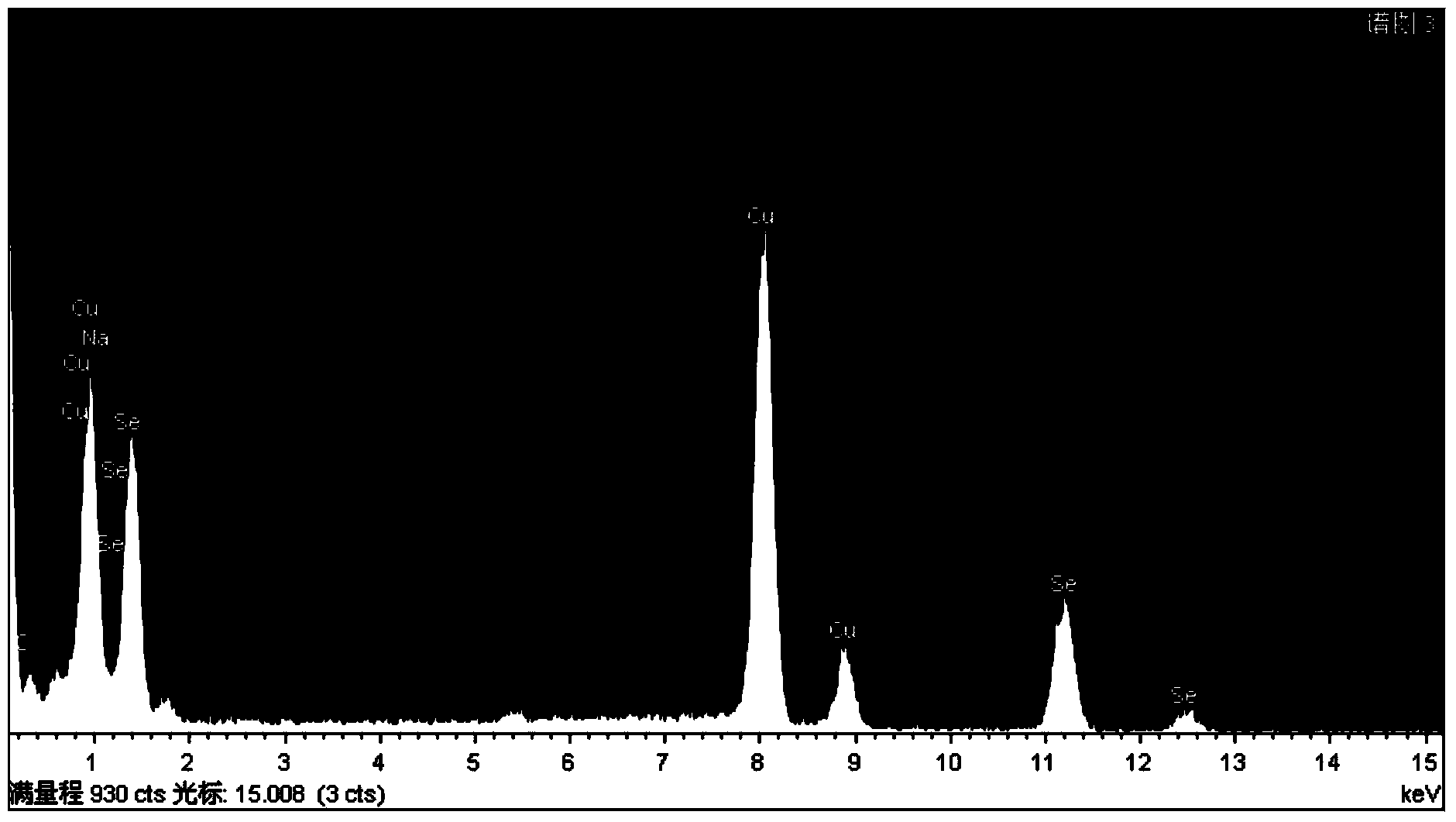

[0044] 1 gram of chitosan was dissolved in an appropriate amount of 1% acetic acid solution, 0.4 gram of ascorbic acid was added, after fully dissolving, 100 mg of sodium selenite was added, and the reaction was stirred until the red color in the solution did not deepen any more, and nanometer elemental selenium sol was obtained. Another 100 g of sucrose was completely dissolved in 200 ml of deionized water to obtain a sucrose solution. The nano elemental selenium sol and the sucrose solution are fully mixed to prepare the powder spraying liquid. The powder spray liquid is spray-dried, the hot air inlet temperature of the spray dryer is 190°C, the outlet temperature is 110°C, and the gauge pressure at the atomizer is 2MPa. After spray drying, a reddish-brown powder nanometer elemental selenium / sucrose complex is obtained. The light reddish brown solid powder is observed under a scanning electron microscope (SEM), and the image is as follows figure 1 shown. The light reddish...

Embodiment 2

[0046] Dissolve 1 gram of sodium carboxymethyl cellulose in an appropriate amount of deionized water, add 0.6 gram of ascorbic acid, after fully dissolving, add 60 mg of selenium dioxide, stir and react until the red color in the solution does not deepen any more, and obtain nanometer elemental selenium sol. Another 150 grams of glucose was taken and completely dissolved in 250 ml of deionized water to obtain a glucose solution. The nano elemental selenium sol and the glucose solution are fully mixed to prepare the powder spraying liquid. The powder spray liquid is spray-dried, the hot air inlet temperature of the spray dryer is 180°C, the outlet temperature is 105°C, and the gauge pressure at the atomizer is 1.5MPa. After spray drying, a reddish-brown powdery nanometer elemental selenium / carboxymethyl cellulose composite was obtained.

Embodiment 3

[0048] Dissolve 1 gram of sodium alginate in an appropriate amount of deionized water, add 100 mg of sodium selenate, fully stir to dissolve, add 0.6 gram of sodium borohydride, stir and react until the red color in the solution no longer deepens, and obtain nanometer elemental selenium sol. Another 200 grams of chitosan oligosaccharides was completely dissolved in 500 ml of deionized water to obtain a chitosan oligosaccharide solution. The nano elemental selenium sol and the chitosan oligosaccharide solution are fully mixed to prepare a powder spraying solution. The spray powder liquid is spray-dried, the hot air inlet temperature of the spray dryer is 160°C, the outlet temperature is 85°C, and the gauge pressure at the atomizer is 1.5MPa. After spray drying, a reddish-brown powdery nanometer elemental selenium / chitooligosaccharide complex is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com