Rana japonica oil collagen peptide moisturizing sun cream and preparation process thereof

The technology of collagen peptide and Rana oleifera oil is applied in the directions of dressing preparations, cosmetic preparations, preparations for skin care, etc., can solve problems such as skin damage and seriousness, and achieves safe raw materials, uniform application, and simple and easy preparation method. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

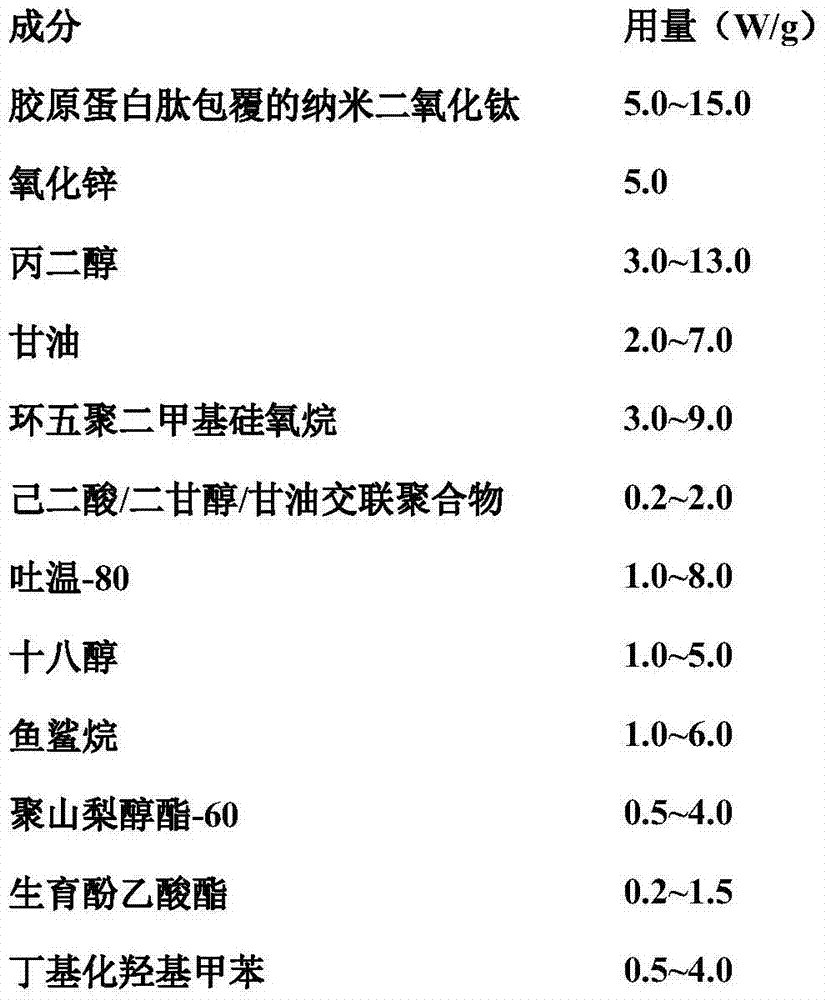

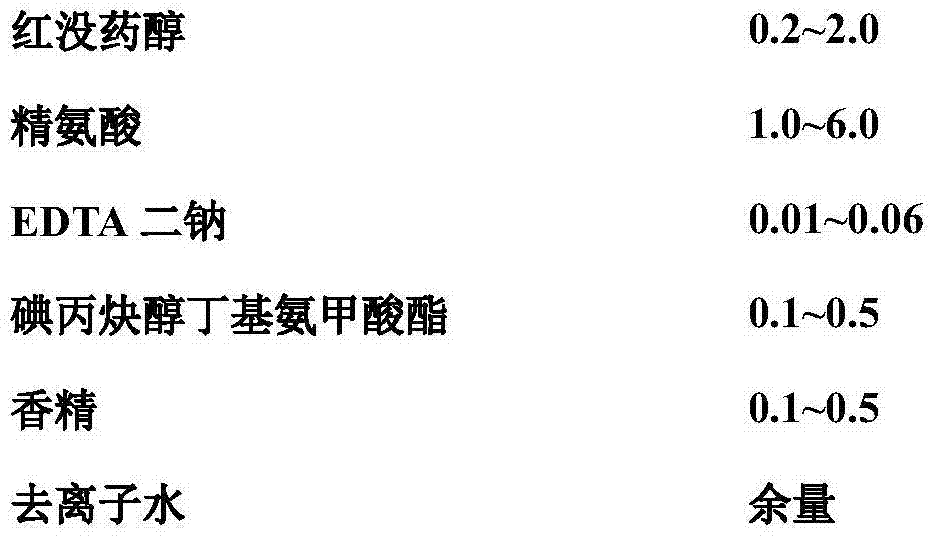

Image

Examples

Embodiment 1

[0023] Enzymatic hydrolysis of wood frog oil to produce collagen peptides: Weigh dry wood frog oil, soak in 100 times distilled water at 4°C for 12 hours; grind and homogenize; heat in a boiling water bath, and heat-treat at 90°C for 10 minutes to obtain a suspension solution; cool the suspension to 60°C; add 5% protease by weight of dry Rana oil; at 70°C and pH 7, enzymolyze in a constant temperature water bath for 6 hours, accompanied by magnetic stirring during the process; after enzymolysis, Inactivate the enzyme at 85°C for 15 minutes; cool to room temperature to obtain the collagen peptide of Rana oil.

[0024] Rana oil collagen peptide-coated nano-titanium dioxide: Weigh a certain amount of titanium sulfate and prepare a 1.2mol / L titanium sulfate solution; take the prepared titanium sulfate solution, add Rana oil hydrolyzate at a volume ratio of 4:1, and add Mix a certain amount of urea; heat in a water bath at 80°C for 5 hours with slow stirring; after the reaction is ...

Embodiment 2

[0027] Enzymatic hydrolysis of wood frog oil to produce collagen peptides: Weigh dry wood frog oil, soak in 100 times distilled water at 4°C for 12 hours; grind and homogenize; heat in a boiling water bath, and heat-treat at 90°C for 10 minutes to obtain a suspension solution; cool the suspension to 60°C; add 3% protease by weight of dry Rana oil; at 70°C and pH 7, perform enzymolysis in a constant temperature water bath for 6 hours, accompanied by magnetic stirring during the process; after enzymolysis, Inactivate the enzyme at 85°C for 15 minutes; cool to room temperature to obtain the collagen peptide of Rana oil.

[0028] Rana oil collagen peptide-coated nano-titanium dioxide: Weigh a certain amount of titanium sulfate and prepare a 1.2mol / L titanium sulfate solution; take the prepared titanium sulfate solution, add Rana oil hydrolyzate at a volume ratio of 4:1, and add Mix a certain amount of urea; heat in a water bath at 80°C for 5 hours with slow stirring; after the rea...

Embodiment 3

[0031] Enzymatic hydrolysis of wood frog oil to produce collagen peptides: Weigh dry wood frog oil, soak it with 100 times distilled water at 4°C for 12 hours; grind and homogenize; heat in a boiling water bath, and heat-treat at 90°C for 10 minutes to obtain a suspension solution; cool the suspension to 60°C; add 5% protease by weight of dry Rana oil; at 70°C and pH 7, enzymolyze in a constant temperature water bath for 6 hours, accompanied by magnetic stirring during the process; after enzymolysis, Inactivate the enzyme at 85°C for 15 minutes; cool to room temperature to obtain the collagen peptide of Rana oil.

[0032]Rana oil collagen peptide-coated nano-titanium dioxide: Weigh a certain amount of titanium sulfate and prepare a 1.2mol / L titanium sulfate solution; take the prepared titanium sulfate solution, add Rana oil hydrolyzate at a volume ratio of 5:1, and add Mix a certain amount of urea; heat in a water bath at 80°C for 5 hours with slow stirring; after the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com