Electrostatic spinning nanofiber-extracellular matrix composite material as well as preparation method and application thereof

A technology of electrospinning and nanofibers, which is applied in the field of electrospinning nanofibers-extracellular matrix composite materials and its preparation, can solve the problems of ineffective resistance to soft tissue pressure and poor mechanical properties, and achieve high application prospects and Practical value, good mechanical properties, enhanced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

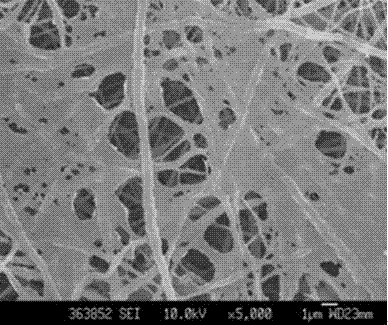

[0034] 1. Preparation of electrospun fiber membranes of biodegradable materials:

[0035] (1) Weigh 160mg of PCL (molecular weight: 100,000), dissolve it in 2ml of a mixed solvent of dichloromethane and N,N-dimethylformamide (8:1, CH 2 Cl 2 / DMF, v / v), to prepare a PCL solution with a concentration of 80 mg / mL, seal it with a parafilm, stir it magnetically for 3 hours, and set aside.

[0036] (2) Put the PCL solution prepared in step (1) into the syringe of the electrospinning device, adjust the parameters of the micro propulsion pump, the capacity is 0.2 ml, the propulsion speed is 1.0 ml / hour, and run. Turn on the rotating device and adjust the speed to make the rotation stable. Turn on the high-voltage power supply, adjust the voltage value to 20 kV, start spinning, and receive the spinning along the direction of the tinfoil receiver.

[0037] (3) After spinning (about ten minutes), remove the tinfoil, and use a glass rod to remove the prepared spun fiber membrane along th...

Embodiment 2

[0044] 1. Preparation of electrospun fiber membranes of biodegradable materials:

[0045] (1) Weigh 200mg of PLGA (molecular weight 150,000, the ratio of lactic acid to glycolic acid is 9:1), dissolve it in 2ml of a mixed solvent of dichloromethane and N,N-dimethylformamide (6:1, CH 2 Cl 2 / DMF, v / v) to prepare a PLGA solution with a concentration of 100 mg / mL, seal it with parafilm, stir it magnetically for 3 hours, and set aside.

[0046] (2) Put the PLGA solution prepared in step (1) into the syringe of the electrospinning device, adjust the parameters of the micro propulsion pump, the capacity is 0.2 ml, the propulsion speed is 0.4 ml / hour, and run. Turn on the rotating device and adjust the speed to make the rotation stable. Turn on the high-voltage power supply, adjust the voltage value to 10 kV, start spinning, and receive the spinning along the direction of the tinfoil receiver.

[0047] (3) After spinning (about ten minutes), remove the tinfoil, and use a glass ro...

Embodiment 3

[0055] 1. Preparation of electrospun fiber membranes of biodegradable materials:

[0056] (1) Weigh 120mg of PLLA (molecular weight: 200,000), dissolve it in 2ml of a mixed solvent of dichloromethane and N,N-dimethylformamide (9:1, CH 2 Cl 2 / DMF, v / v) to prepare a PLLA solution with a concentration of 60 mg / mL, seal it with parafilm, stir it magnetically for 3 hours, and set aside.

[0057] (2) Put the PLLA solution prepared in step (1) into the syringe of the electrospinning device, adjust the parameters of the micro propulsion pump, the capacity is 0.2 ml, the propulsion speed is 0.5 ml / hour, and run. Turn on the rotating device and adjust the speed to make the rotation stable. Turn on the high-voltage power supply, adjust the voltage value to 14 kV, start spinning, and receive the spinning along the direction of the tinfoil receiver.

[0058] (3) After spinning (about ten minutes), remove the tinfoil, and use a glass rod to remove the prepared spun fiber membrane along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com