A method for preparing cell membrane sheet using sodium alginate hydrogel

A sodium alginate and cell membrane technology, which is applied in prosthesis, medical science and other directions, can solve the problems of difficulty in obtaining seed cells, limited popularization and application, complicated technical operation, etc., and achieves easy cell adhesion and value-added, good application prospects, and operation steps. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

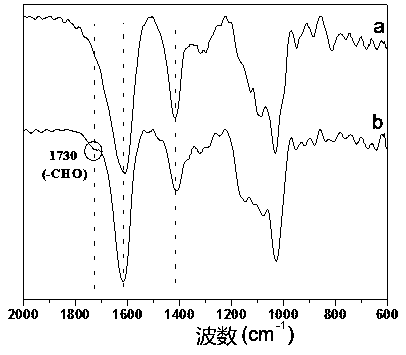

[0066] Example 1 Oxidation of sodium alginate

[0067] Sodium alginate is a polysaccharide with a cis-o-diol structure. When reacting with sodium periodate, sodium periodate can promote the C-C bond breakage of sodium alginate, and oxidize the adjacent diol structure into a more reactive adjacent aldehyde structure. The introduction of the new functional group aldehyde group provides more means for the surface modification of sodium alginate, which is a commonly used modification method for biomaterials.

[0068] 1. Weigh 0.2 g of sodium alginate and dissolve it in 10 mL of pure water. A certain amount of sodium periodate was added, and the reaction was stirred for 1 h in the dark, and the stirring speed was 300 rpm. After 1 h, add ethylene glycol in the amount of sodium periodate and other substances to the solution, and continue the reaction for 0.5 h. After the reaction was completed, the above solution was added to the dialysis bag for dialysis for 3 days, during which ...

Embodiment 2

[0071] Example 2 Preparation of Sodium Alginate Hydrogel Base Material

[0072] 1. Weigh a certain mass of sodium alginate and an equal mass of OSA80 (prepared in Example 1, oxidized sodium alginate) to form a mixed solution with a total sodium alginate concentration of 2% w / v. At the same time, add Add sodium chloride to make the final concentration of sodium chloride 1 mol / L. After the above solution is mixed evenly, add 0.5 mL per well to a 6-well culture plate, freeze at -80°C overnight, and then freeze-dry in a vacuum freeze dryer. At the same time, prepare materials without adding sodium chloride and freeze them under the same conditions. dry as a control.

[0073] 2. Fix the material on the sample stage, spray it with gold, put it in the vacuum chamber of the cold field emission scanning electron microscope, and observe it at a voltage of 15 kV to obtain the SEM observation picture. Such as figure 2 As shown, where A, B are sodium alginate base materials with poroge...

Embodiment 3

[0075] Example 3 Surface Grafting of COL-I on Sodium Alginate Scaffold

[0076] 1. Submerge the material prepared in Example 2 in dehydrated ethanol completely, then slowly add 2% w / v calcium chloride solution, after the added calcium chloride solution is equal to the volume of dehydrated ethanol, use 2% The calcium chloride solution was used to cross-link and wash the material, and finally, the calcium chloride solution remaining in the material was removed by washing with deionized water.

[0077] 2. After the material was sterilized by soaking in ethanol for 3 hours, it was air-dried naturally, and 0.5 mL of COL-I solution (1 mg / mL) dissolved in 0.2 mmol / L glacial acetic acid was added to each well, and cross-linked in a refrigerator at 4 °C for 24 hours. The bacterial water was washed 3 times to obtain the surface-modified sodium alginate hydrogel, which was the base material for the preparation of cell membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com