A honeycomb waste gas denitrification catalyst

A denitrification catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of green body cracking, excessive addition, and reduced yield, so as to reduce cracking and reduce Dosage, the effect of increasing the firing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh various components according to the following proportions:

[0031] Titanium dioxide powder: 83 parts;

[0032] Tungsten trioxide: 8 parts;

[0033] Vanadium pentoxide: 1.5 parts;

[0034] Silicon dioxide: 1.5 parts;

[0035] Fiberglass: 6 parts;

[0036] Stearic acid: 1 part;

[0037] RP-CHOP fiber: 0.5 parts;

[0038] Aminocellulose: 0.3 parts.

[0039] Mix the powders other than silica evenly first, then mix the silica sol with water evenly, and mix with various powders. The mud is stale, extruded, dried, fired, cut, and packaged. The finished honeycomb exhaust gas catalyst is obtained.

Embodiment 2

[0041] Weigh various components according to the following proportions:

[0042] Titanium dioxide powder: 84 parts;

[0043] Tungsten trioxide: 5 parts;

[0044] Vanadium pentoxide: 1 part;

[0045] Silicon dioxide: 5 parts;

[0046] Fiberglass: 5 parts;

[0047] Stearic acid: 0.5 part;

[0049] Aminocellulose: 0.5 parts.

[0050] Mix the powders other than silica evenly first, then mix the silica sol with water evenly, and mix with various powders. The mud is stale, extruded, dried, fired, cut, and packaged. The finished honeycomb exhaust gas catalyst is obtained.

Embodiment 3

[0052] Weigh various components according to the following proportions:

[0053] Titanium dioxide powder: 80 parts;

[0054] Tungsten trioxide: 8 parts;

[0055] Vanadium pentoxide: 2 parts;

[0056] Silicon dioxide: 5 parts;

[0057] Fiberglass: 5 parts;

[0058] Stearic acid: 1 part;

[0059] RP-CHOP fiber: 0.5 parts;

[0060] Aminocellulose: 0.5 parts.

[0061] Mix the powders other than silica evenly first, then mix the silica sol with water evenly, and mix with various powders. The mud is stale, extruded, dried, fired, cut, and packaged. The finished honeycomb exhaust gas catalyst is obtained.

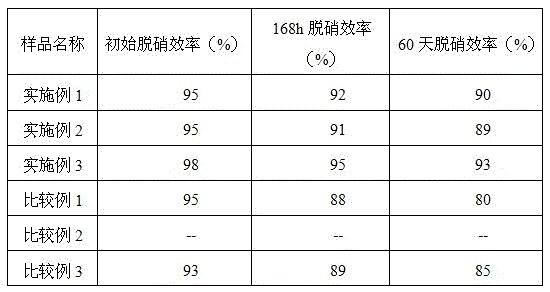

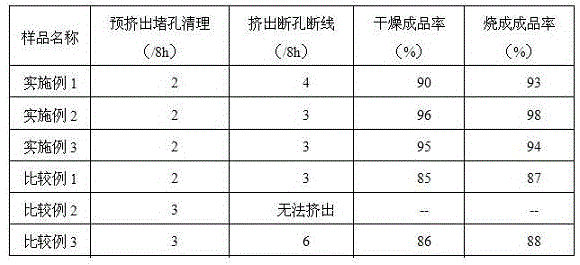

[0062] In order to investigate the influence of RP-CHOP fiber on various performances of the honeycomb denitration catalyst, the following comparative examples were made for comparison.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com