Hydroxyl magnesium silicate nanotube wear-resistant material and preparation method thereof

A technology of hydroxymagnesium silicate and nanotubes, which is applied in the direction of magnesium silicate, silicate, nanotechnology, etc., can solve the problems of high energy consumption and cost, and achieve the effect of simple method, uniform scale and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

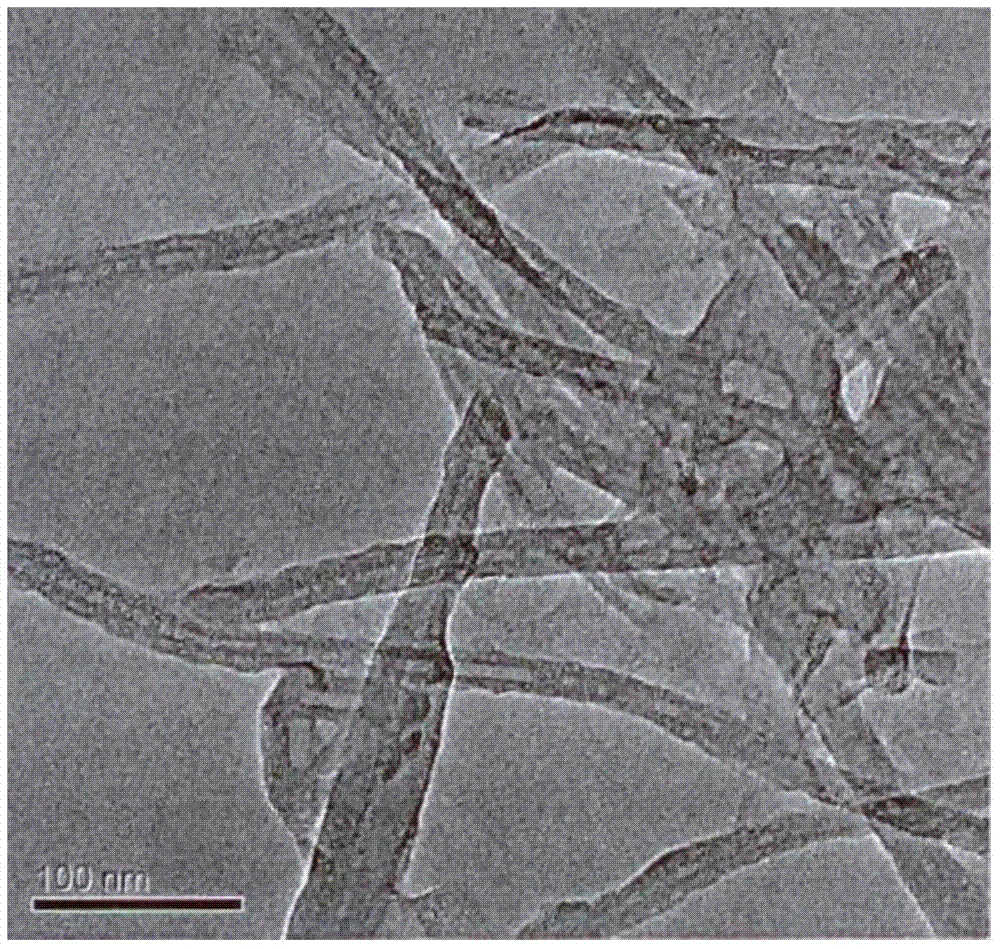

[0020] Embodiment 1: Synthesis and characterization of hydroxymagnesium silicate nanotubes

[0021] 1. Magnesium chloride, sodium silicate and sodium hydroxide are used as raw materials

[0022] 6.09 grams of magnesium chloride (Mg 2 Cl 2 ·6H 2 O), 5.68 grams of sodium silicate (Na 2 SiO 3 9H 2 O) Add to 80 ml of 0.1mol / L sodium hydroxide solution, stir evenly at room temperature, add to a 100mL reaction kettle, put into an oven and react at 150°C for 48 hours. After the reaction is completed, the reaction solution is centrifuged to obtain a solid, which is washed with 10 ml of water and ethanol in sequence, and dried to obtain magnesium hydroxysilicate nanotubes.

[0023] 2. Magnesium nitrate, diatomaceous earth and potassium hydroxide are used as raw materials

[0024] 4.44 grams of magnesium nitrate (Mg(NO 3 ) 2 ), 1.2 grams of diatomaceous earth, were added to 80 ml of saturated potassium hydroxide solution, put into a 100 ml reaction kettle, stirred evenly, and r...

Embodiment 2

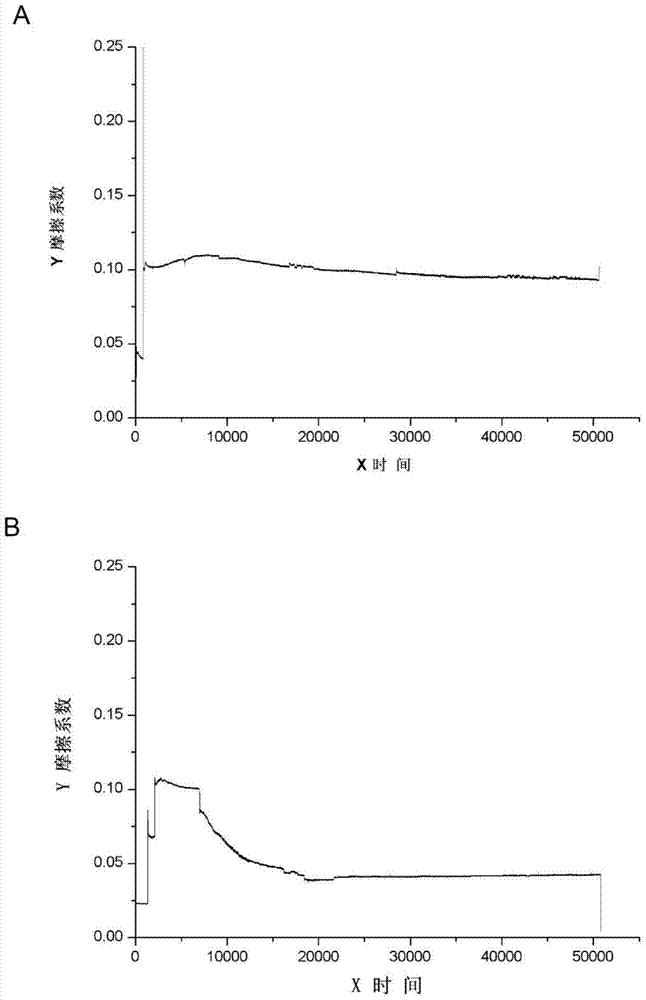

[0025] Example 2: Results for Tribological Surface Treatment

[0026] Test equipment: FALEX friction and wear testing machine

[0027] Test conditions:

[0028] Lubrication form: oil-immersed lubrication Test temperature: room temperature; 22°C

[0029] Contact type: Surface contact Test load: 15lbs

[0030] Test speed: 800rpm Sample material: 45# steel

[0031] Test time: 850 minutes / each time

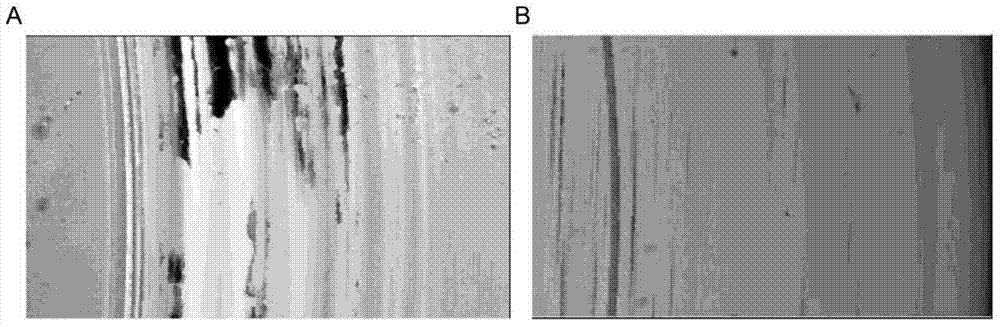

[0032] Magnesium hydroxysilicate nanotubes are added to the base oil at a ratio of 0.01-1%, and friction experiments are carried out on a FALEX friction and wear testing machine. In a preferred example of the present invention, when the addition ratio of hydroxymagnesium silicate nanotubes in the lubricating oil is 0.1%, compared with the lubricating oil without adding hydroxymagnesium silicate nanotubes ( figure 2 A), able to significantly reduce the coefficient of friction ( figure 2 B), reduced to 40%-50% of the original. Compared with lubricating oil without adding hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com