Precipitated calcium carbonate production technology for reducing magnesium and increasing calcium

A technology of precipitating calcium carbonate and production process, applied in the direction of calcium carbonate/strontium/barium, etc., to achieve the effect of improving purification effect, high mass transfer efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

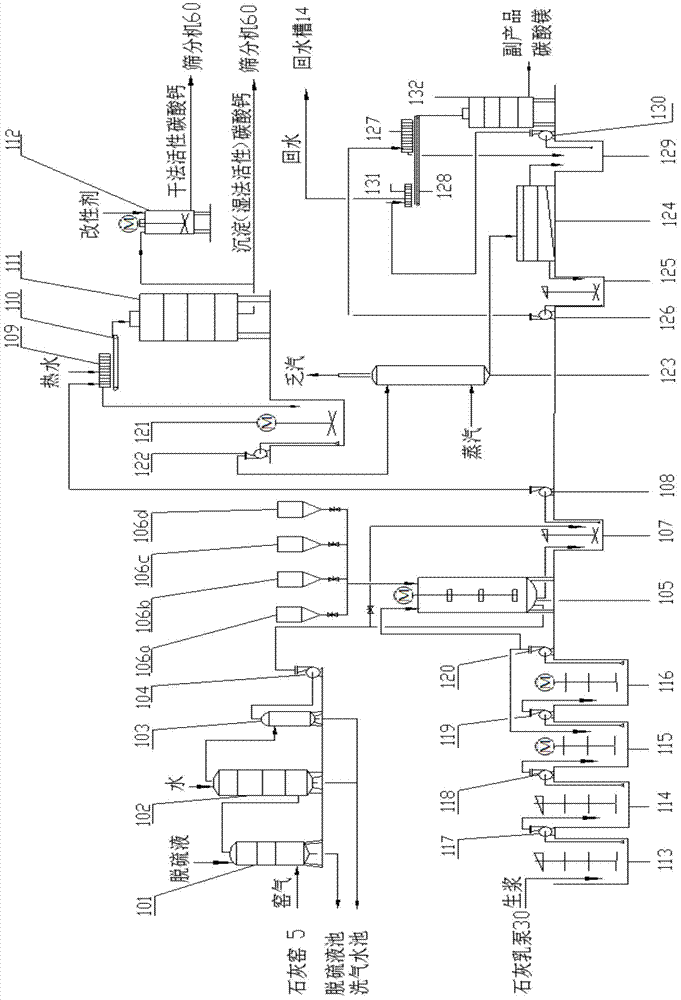

[0050] The technological process of the present embodiment is:

[0051] 1) Kiln gas purification process

[0052] The kiln gas produced by the lime kiln 5 (see "Inorganic Salt Technology", Zhou Youying. Chemical Press, page 168) is passed into the lower part of the desulfurization tower 101, and the desulfurized kiln gas flows out from the top of the desulfurization tower 101, and then enters the washing The lower part of the tower 102 flows out from the top of the washing tower 102 (at this time, the temperature of the kiln gas drops to 40°C, CO 2 The volume content of the kiln gas is 30% of the kiln gas), and enters the gas-liquid separator 103;

[0053] Among them, the liquid phase in the desulfurization tower is water, and the liquid phase contains a desulfurization agent with a mass ratio of 1.5%, and the composition of the desulfurization agent is CaO, CaCO 3 and MgO, whose mass ratio is CaO:CaCO 3 :MgO=1:1:0.5.

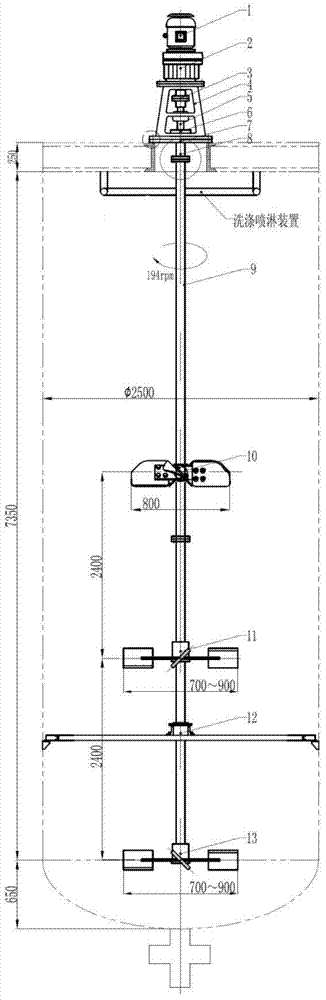

[0054] 2) Lime milk pre-aging + dynamic aging process...

Embodiment 2

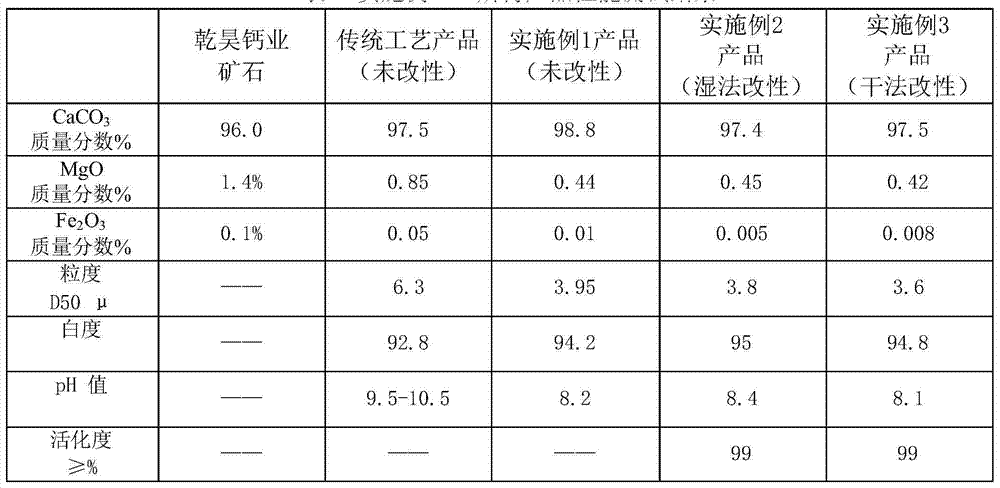

[0069] The changes in this example are: the amount of sodium polyacrylate added in process 3) was changed to 0.2% of the mass of calcium carbonate, carbonization was carried out for 90 minutes until the pH value of the slurry reached 7.0, and carbonization was continued for 10 minutes; then calcium carbonate was added After whitening treatment (stirring for 60 minutes) with 2% by mass of whitening agent (sodium dithionite), 2% by mass of calcium carbonate modifier ammonium stearate was added through additive head tank 106d for wet modification (stirring for 60 minutes ), and then put into the cooked pulp tank to complete the carbonization process; other process steps are the same as

[0070] Example 1.

[0071] The performance test result of gained product calcium carbonate is shown in Table 1.

Embodiment 3

[0073] The changes in this example are: in step 3), add additive A sodium polyacrylate and additive B citrate with a theoretically generated calcium carbonate mass of 0.3% respectively, carbonize for 90 minutes until the pH value of the slurry reaches 7.0, and continue carbonizing for 30 minute. After adding whitening agent (sodium dithionite) with 2% calcium carbonate mass for whitening treatment (stirring for 60 minutes), in step 4) according to customer needs, the product is modified by dry method: calcium carbonate in cooked pulp tank 107 The slurry is sent to the plate and frame filter press 109 by the cooked pulp pump 108, dehydrated until the water content of the filter cake is 30% by mass, and the filter cake is sent by the belt conveyor 110 to the disc dryer 111 for drying until the water content by mass is less than 0.5% Finally, the calcium carbonate is sent into the kneader 112, and the modifier borate coupling agent (produced by Fujian Tianbao Plastic Co., Ltd.) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com