Method of preparing superfine monolayer transition metal compound quantum dot solution

A quantum dot solution, transition metal technology, applied in tungsten compounds, niobium compounds, chemical instruments and methods, etc., can solve problems such as poor crystallinity, and achieve the effects of good repeatability, easy industrial production, and short reaction cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

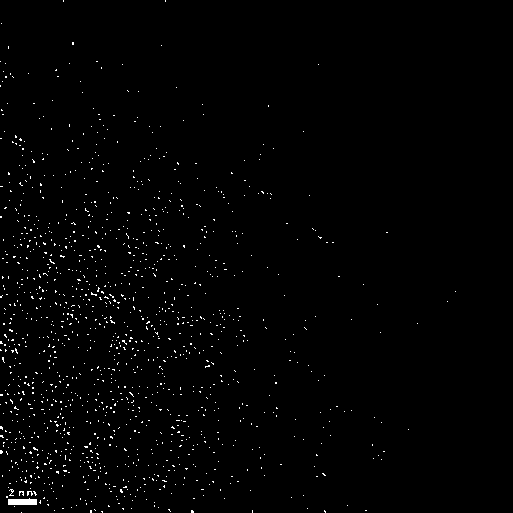

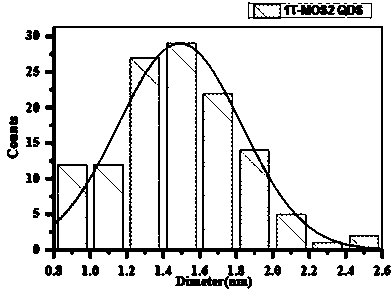

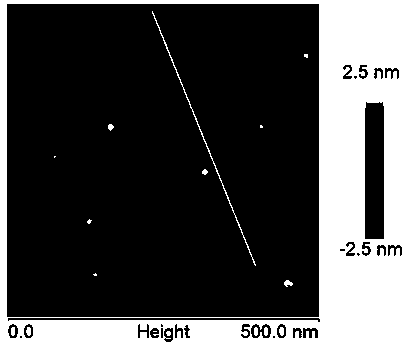

[0024] Example 1 Ultra-small single-layer MoS 2 Preparation of quantum dot solution

[0025] (1) Mix 1.6M n-butyllithium solution and 2H-MoS 2 The solution was added to the reaction kettle liner in the argon-filled glove box and mixed, in which the n-butyllithium solution was mixed with 2H-MoS 2 The molar ratio is 3:1, placed in an incubator at 90 O After reacting at C for 12 hours, wash the incompletely reacted n-butyllithium in the glove box with n-hexane after the end of the reaction to obtain the intermediate product Li n MoS 2, (n is a single MoS 2 The number of Li atoms occupied after the reaction, the value of n will change with the reaction time, reaction temperature, and the mass ratio of the reactants, 0<n<1.5);

[0026] (2) Place the intermediate product obtained in step 1 in a vacuum oven for 40 O C, vacuum-dried for 30 min to obtain a dry product weighing 1 g;

[0027] (3) According to the mass volume ratio (g / ml), add 300 ml of deionized water to the dried...

Embodiment 2

[0036] Example 2 Ultra-small single-layer WS 2 Quantum dot solution preparation

[0037] (1) Mix 2.2M n-butyllithium solution and WS 2 The solution was added to the reaction kettle liner in the glove box filled with argon and mixed, wherein the n-butyllithium solution was mixed with WS 2 The molar ratio is 4:1, placed in an incubator at 80 O After 24 hours of insulation reaction at C, wash the incompletely reacted n-butyllithium in the glove box with n-hexane solvent to obtain the intermediate product Li n WS 2 (n is a single layered WS 2 The number of Li atoms occupied after the molecular reaction is completed, the n value will change with the reaction time, reaction temperature, and the mass ratio of the reactant, 0<n<1.5);

[0038] (2) Put the intermediate product obtained in step 1 into a vacuum drying oven, 40 O C, vacuum-dried for 30 min to obtain a dry product, weighing 1.1 g of the dry product;

[0039] (3) Add deionized water to the dried product obtained in st...

Embodiment 3

[0041] Example 3 Ultra-small monolayer MoSe 2 Quantum dot solution preparation

[0042] (1) Mix 2.4 M n-butyllithium solution and MoSe 2 The solution was added to the reaction kettle liner in a glove box filled with argon and mixed, in which the n-butyllithium solution was mixed with MoSe 2 The molar ratio is 6:1, placed in an incubator at 90 O After 36 hours of insulation at C, wash the incompletely reacted n-butyllithium in the glove box with n-hexane after the reaction to obtain the intermediate product Li n MoSe 2 (n is a single layered MoSe 2 The number of Li atoms occupied after the molecular reaction is completed, the n value will change with the reaction time, reaction temperature, and the mass ratio of the reactant, 0<n<1.5);

[0043] (2) Put the intermediate product obtained in step 1 into a vacuum drying oven, 40 O C, vacuum-dried for 30 min to obtain a dried product, weighing 1.13 g of the dried product;

[0044] (3) Add deionized water to the dried product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com