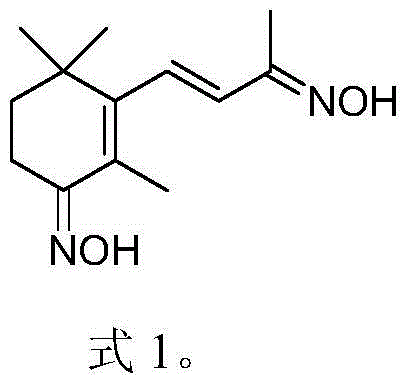

Dioxime ionone as well as preparation method and application thereof

A technology of ionone and ionone molarity, applied in oxime preparation, hydrolysis preparation of carbonyl compounds, organic chemistry, etc., can solve the problems of low process yield, low yield, difficult vacuum distillation or recrystallization, etc. The effect of simple route, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

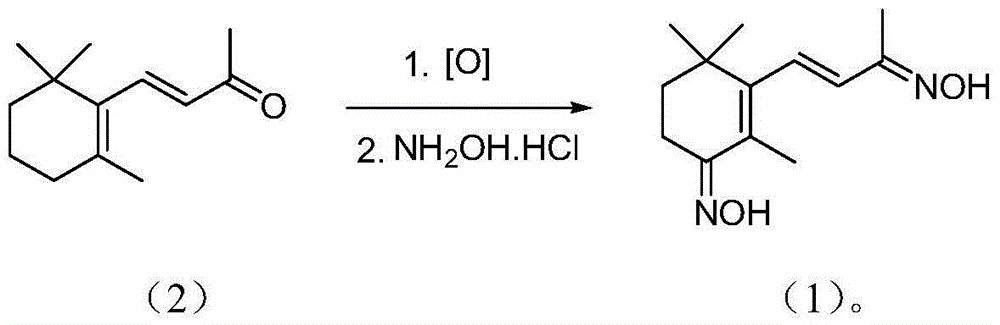

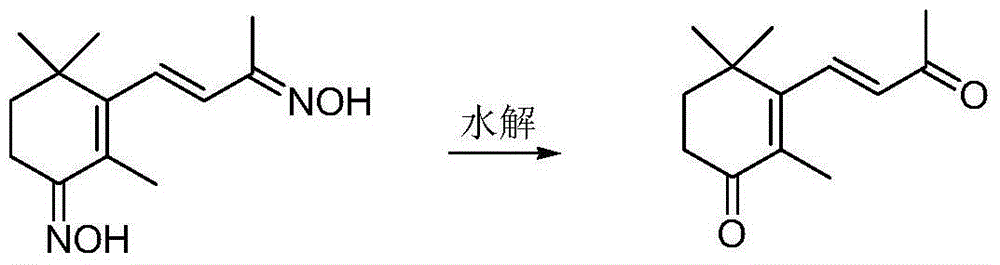

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of dioxime-ionone (1)

[0031] Add 96g (0.5mol) β-ionone, 9g (0.05mol) NHPI and 1.3g (5.0mmol) cobalt acetylacetonate successively in a 250mL four-neck flask, stir mechanically, and pass oxygen at 60°C. Gas chromatography followed and detected the reaction until the raw material content was less than 5%. The above reaction solution was cooled to room temperature, transferred to a 1000mL four-neck flask, added 500mL of 50% (volume ratio) ethanol aqueous solution, 69.5g (1mol) of hydroxylamine hydrochloride and 82g sodium acetate (1mol), and refluxed for 2 hours. Cool down, evaporate the solvent to dryness, add 400mL dichloromethane and 250mL water to the residue, stir for half an hour, separate layers, evaporate the solvent in the lower dichloromethane layer, recrystallize with 300mL ethyl acetate, filter and dry to obtain a white powder The solid is 60.5g, the liquid chromatography content is 99.2%, the yield is 51.1%, and the melting point is 21...

Embodiment 2~8

[0038] Examples 2-8: Preparation of dioxime-ionone (1) under different bases, solvents and temperature conditions

[0039] Add 9.6g (50mmol) β-ionone, 0.9g (5.0mmol) NHPI and 0.13g (0.50mmol) cobalt acetylacetonate successively into a 100mL four-neck flask, stir mechanically, and pass oxygen at 60°C. Gas chromatography followed and detected the reaction until the raw material content was less than 5%. The above reaction solution was cooled to room temperature, transferred to a 500mL four-neck flask, added 50mL alcoholic aqueous solution, hydroxylamine hydrochloride and alkali, and refluxed for 2 hours. Cool down, evaporate the solvent to dryness, add 40mL dichloromethane to the residue

[0040] Alkanes and 25mL water, stirred for half an hour, separated into layers, evaporated the solvent in the lower methylene chloride layer, recrystallized from ethyl acetate, filtered, dried and weighed, measured the content of the liquid phase, and calculated the yield.

[0041] The resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com