Manufacturing method for SiC-based MOS device gate dielectric thin film

A technology of MOS devices and gate dielectrics, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low carrier mobility, high dielectric constant, low interface state density, etc., and achieve cost reduction , the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

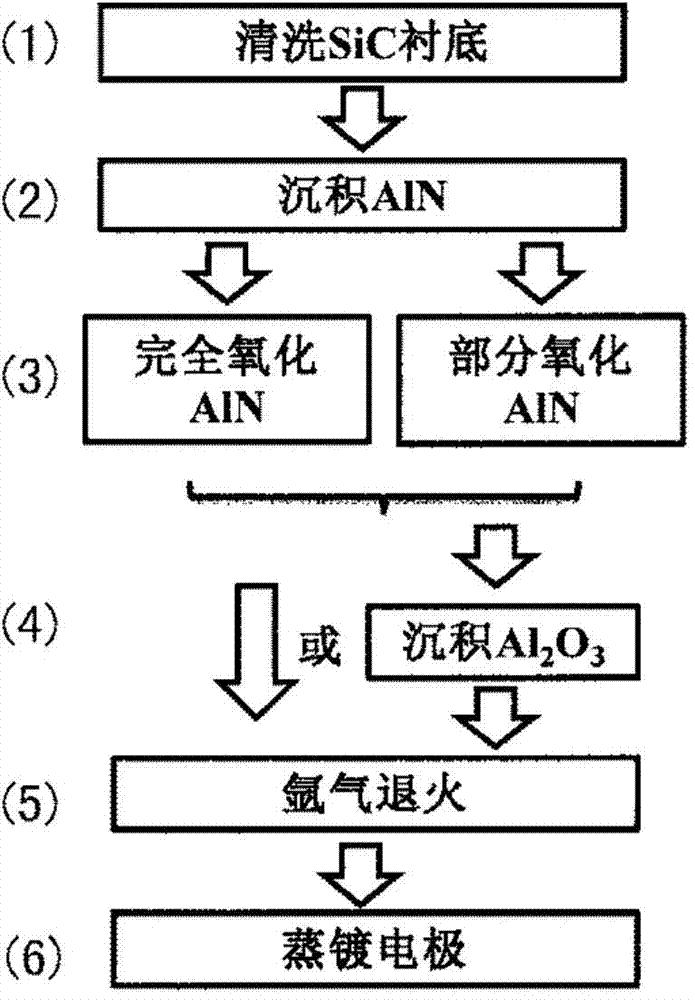

[0020] refer to figure 1 and refer to figure 2 , the invention provides a method for preparing a gate dielectric film for SiC-based MOS devices, comprising the following steps:

[0021] (1) Carry out standard cleaning to SiC substrate 10 samples:

[0022] a. Ultrasonic cleaning with toluene, acetone and ethanol three times in sequence, and then rinse with deionized water.

[0023] b. Soak the rinsed substrate in diluted hydrofluoric acid (hydrogen fluoride: deionized water = 1:3 by volume) for 1 min.

[0024] c. Boil the substrate soaked in hydrofluoric acid in concentrated sulfuric acid for 10 minutes.

[0025] d. Boil the substrate boiled in concentrated sulfuric acid with No. 1 solution and No. 2 solution for 1Smin, then rinse it with deionized water and dry it with nitrogen gas for later use. The No. 1 solution is ammonia water, hydrogen peroxide and deionized water The mixed solution of ammonia water: hydrogen peroxide: deionized water = 1:2:5 by volume, the No. 2 li...

Embodiment 2

[0032] refer to figure 1 and refer to figure 2 , the invention provides a method for preparing a gate dielectric film for SiC-based MOS devices, comprising the following steps:

[0033] Wherein step (1) and (2) are with embodiment 1;

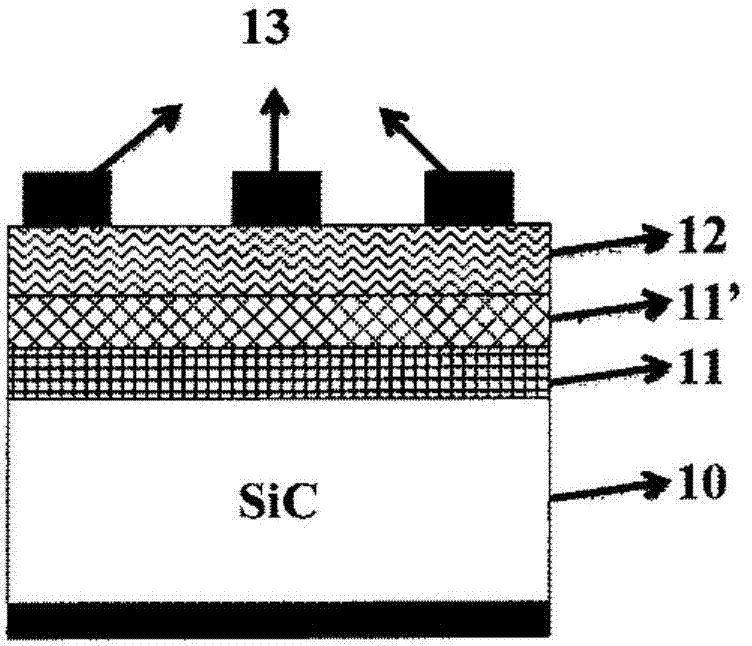

[0034] Step (3) oxidize the AlN thin film 11 to Al by an oxidation method x o y Nz Thin film 11', where x, y, and z are stoichiometric ratios, controlled by the oxidation rate and oxidation time, the AlN film 11 is completely oxidized to Al x o y N z Thin film 11', which is a more stable film than AlN film 11, can play a role in reducing the interface state; the oxidation temperature is 1200°C;

[0035] Step (4) utilize atomic layer deposition to 10nm Al 2 o 3 Thin film 12 is deposited onto Al x o y N z On the film 11', the passivation performance of the Al2O3 film 12 is better, and the dielectric constant is the same as that of the AlN film 11 and Al x o y N z The thin film 11' is close to and can function as a passivation layer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com