Growth method for improving crystal quality of ultraviolet LED epitaxial materials

A technology of LED epitaxial wafers and epitaxial materials, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency of ultraviolet LED chips, difficulties in the preparation of materials for ultraviolet LEDs, and low luminous efficiency of light-emitting areas, etc., to achieve improvement Photoelectric properties, improve crystal quality, improve the effect of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

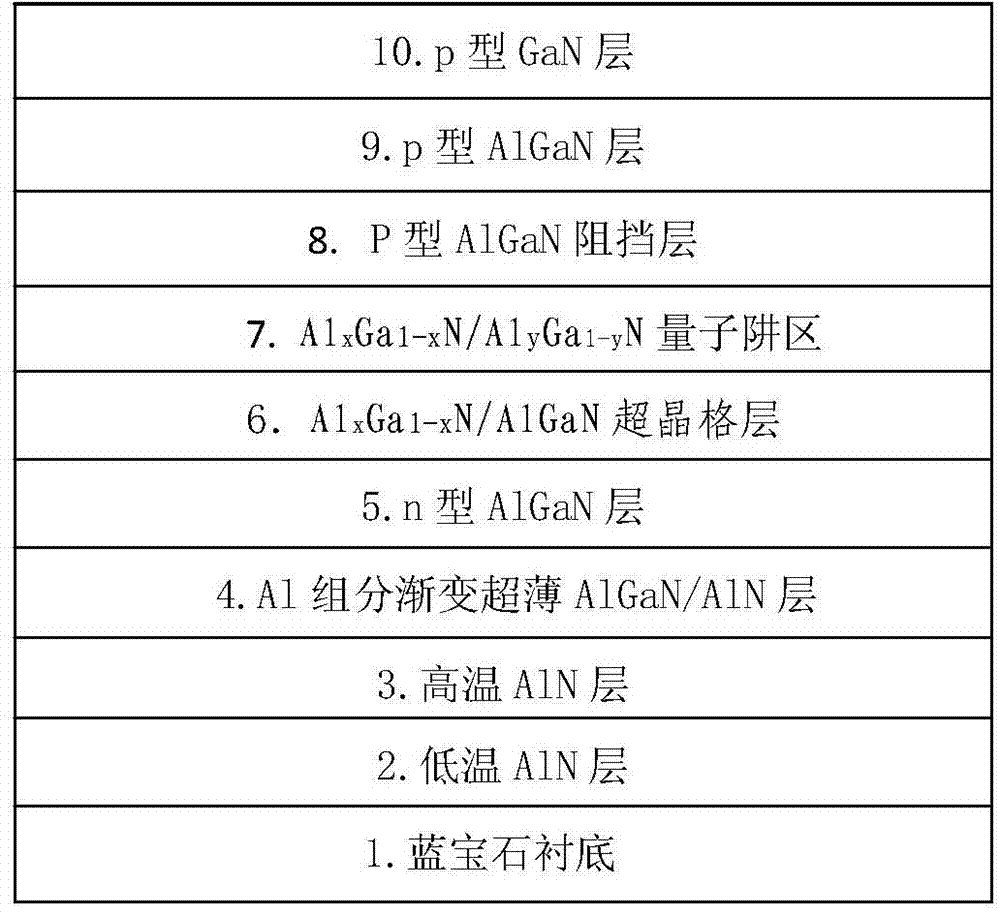

Embodiment Construction

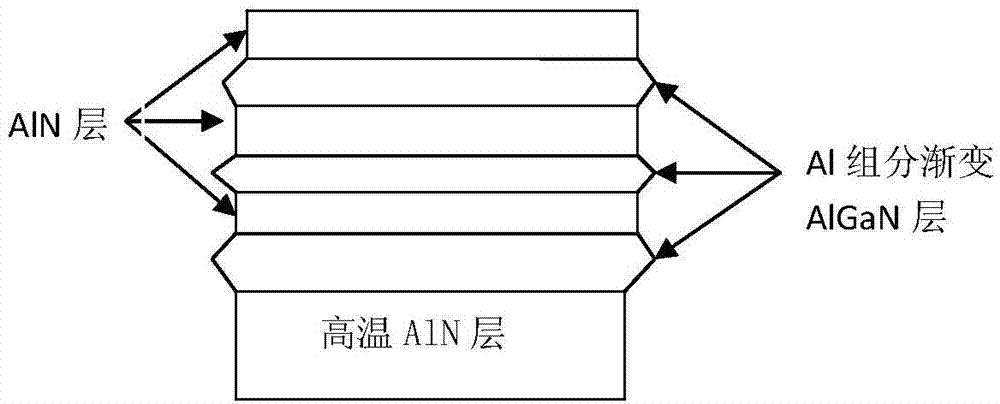

[0044] The present invention uses metal organic compound chemical vapor deposition (MOCVD) epitaxial growth technology, uses sapphire as the growth substrate, and performs heterogeneous epitaxial growth, using trimethylgallium (TMGa), triethylgallium (TEGa), and trimethylindium (TMIn), trimethylaluminum (TMAl) and ammonia (NH3) silane (SiH4) and dimagnesocene (cp2mg) respectively provide gallium source, indium source, aluminum source, and nitrogen source, silicon source, source of magnesium. like figure 1 , 2 As shown, the growth process of the ultraviolet LED epitaxy is as follows:

[0045] 1. After the sapphire substrate is specially cleaned, put it into the MOCVD equipment and bake it at 1100°C for 10 minutes.

[0046] 2. A low-temperature AlN layer with a thickness of 10 nm is grown at a temperature of 600° C., and the growth pressure is 150 torr.

[0047] 3. Raise the temperature to 1070°C to grow a high-temperature AlN layer with a thickness of 300nm, and the growth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com