Catalyst for synthesizing methyl formate by formylating methyl nitrite, preparation method and application of catalyst

A technology of methyl nitrite and methyl formate, applied in the direction of carbon monoxide or formate reaction preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve practical operation difficulties and reaction pressure. high, equipment corrosion and other problems, to achieve the effect of low impurity content, high CO conversion rate and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 1g of magnesium oxide and impregnate it into 17mL of 50mmol / L Ni(NO 3 ) 2 ·6H 2 O ethanol solution, let it stand for 10 hours, dry at 120°C for 10 hours, roast at 500°C for 4 hours, then re-immerse in 1.25mL of 37.6mmol / L potassium chloropalladate aqueous solution, add 4mL of water, and stir for 4 hours. Ultrasonic dispersion for 4 hours, drying at 120°C for 10 hours, calcining at 500°C for 4 hours, and then reducing at 400°C for 5 hours under a high-purity hydrogen atmosphere to obtain PdH used in the formylation of methyl nitrite to methyl formate x - Ni / MgO Catalyst 1 .

Embodiment 2

[0023] Weigh 1g of alumina and impregnate it into 1.25mL of 37.6mmol / L potassium chloropalladate aqueous solution, add 4mL of water, stir for 4 hours, ultrasonically disperse for 4 hours, dry at 120°C for 10 hours, bake at 500°C for 4 hours, and then Reduction at 400°C for 5 hours under a high-purity hydrogen atmosphere to obtain PdH used in the formylation of methyl nitrite to methyl formate x / A1 2 o 3 Catalyst 2.

Embodiment 3

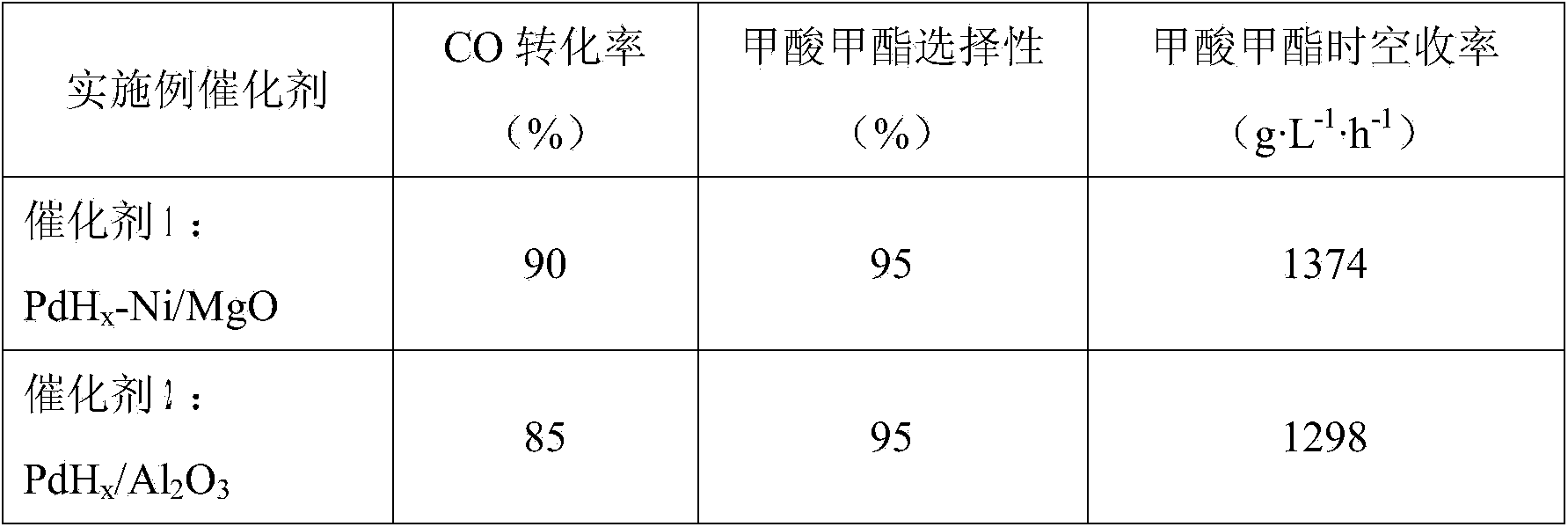

[0025] The catalyst of embodiment 1-2 is applied in methyl nitrite formylation synthesis methyl formate reaction, feed gas ratio is methyl nitrite: carbon monoxide: hydrogen: nitrogen=20: 20: 10: 50 (volume ratio) , the gas phase space velocity is 3000h -1 , the reaction temperature is 120°C, the reaction pressure is 0.1MPa, and the reaction results are shown in Table 1.

[0026] The performance of table 1 embodiment catalyst in methyl nitrite formylation synthetic methyl formate reaction

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com