Transition metal ion concentration gradient doped zinc sulfide or zinc selenide and preparation method thereof

A transition metal ion, graded doping technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems affecting the output laser energy and repetition frequency, the explosion of laser dielectric materials, and the reduction of thermal effects, so as to reduce the probability of non-radiative transition. , the effect of weak electro-acoustic coupling and reduced temperature quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

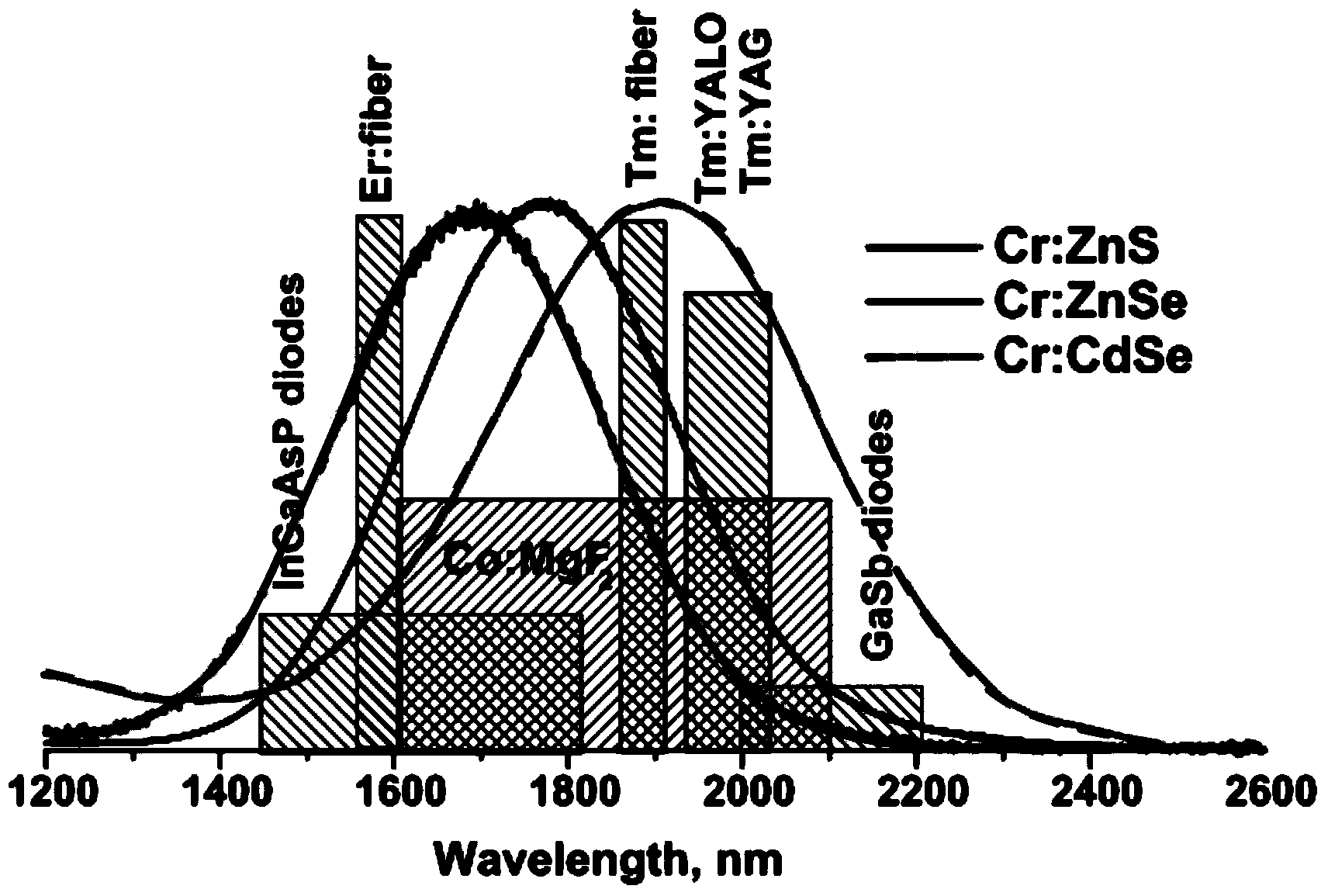

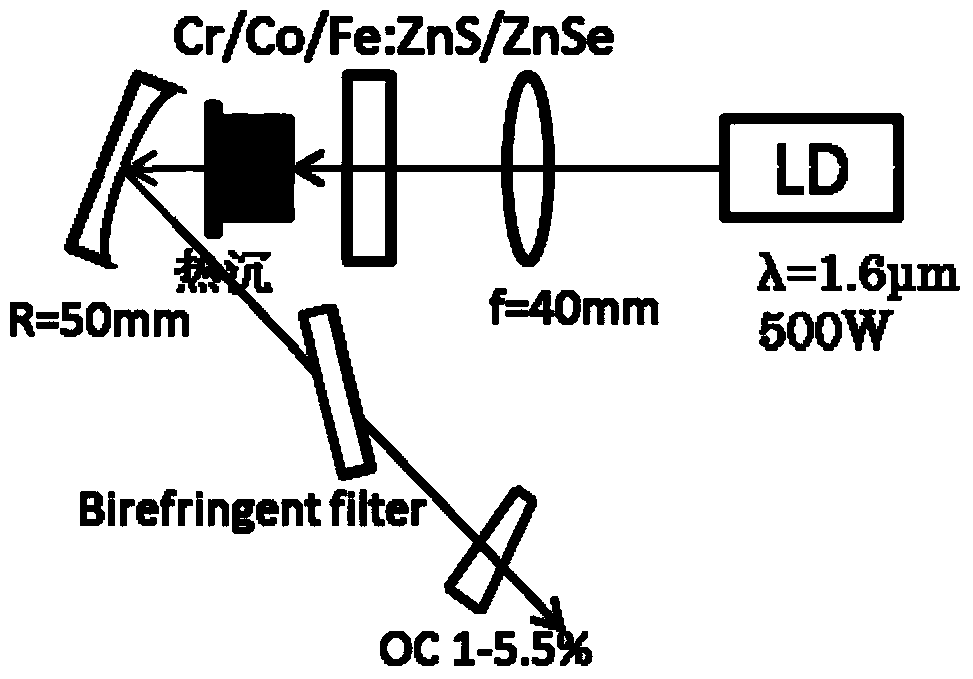

[0026] First, one end of the high-quality ZnS ceramics is evenly vapor-deposited with a metal Cr film, and then placed in a through-N 2 Diffusion at 860°C for 5 days in an atmosphere-protected ampoule to control Cr 2+ The doping concentration of ions, to obtain high-quality Cr 2+ Gradient ion concentration (10 16 ~10 20 ions / cm 3 ) doped zinc sulfide laser material, processed according to the Brewster angle, designed the laser cavity, and completed the laser experiment. figure 1 for Cr 2+ The absorption spectra of ions in ZnS and ZnSe materials and the corresponding pump light sources respectively.

Embodiment 2

[0028] First, one end of the high-quality ZnS ceramics is uniformly vapor-deposited with a metal Co film, and then placed in the H 2 High-temperature diffusion at 900 °C for 15 days in an atmosphere-protected ampoule to control Co 2+ The doping concentration of ions, to obtain high-quality Co 2+ Gradient ion concentration (10 16 ~10 20 ions / cm 3 ) doped zinc sulfide laser material, processed according to the Brewster angle, designed the laser cavity, and completed the laser experiment.

Embodiment 3

[0030] First, one end of high-quality ZnSe ceramics is uniformly vapor-deposited with a metal Fe film, and then placed in a vacuum ampoule and diffused at 1000°C for 10 days at high temperature to control Fe 2+ The doping concentration of ions, to obtain high-quality Fe 2+ Gradient ion concentration (10 16 ~10 20 ions / cm 3 ) doped ZnSe laser material, processed according to the Brewster angle, designed the laser cavity, and completed the laser experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com