Method for preparing chiral intermediate of atorvastatin

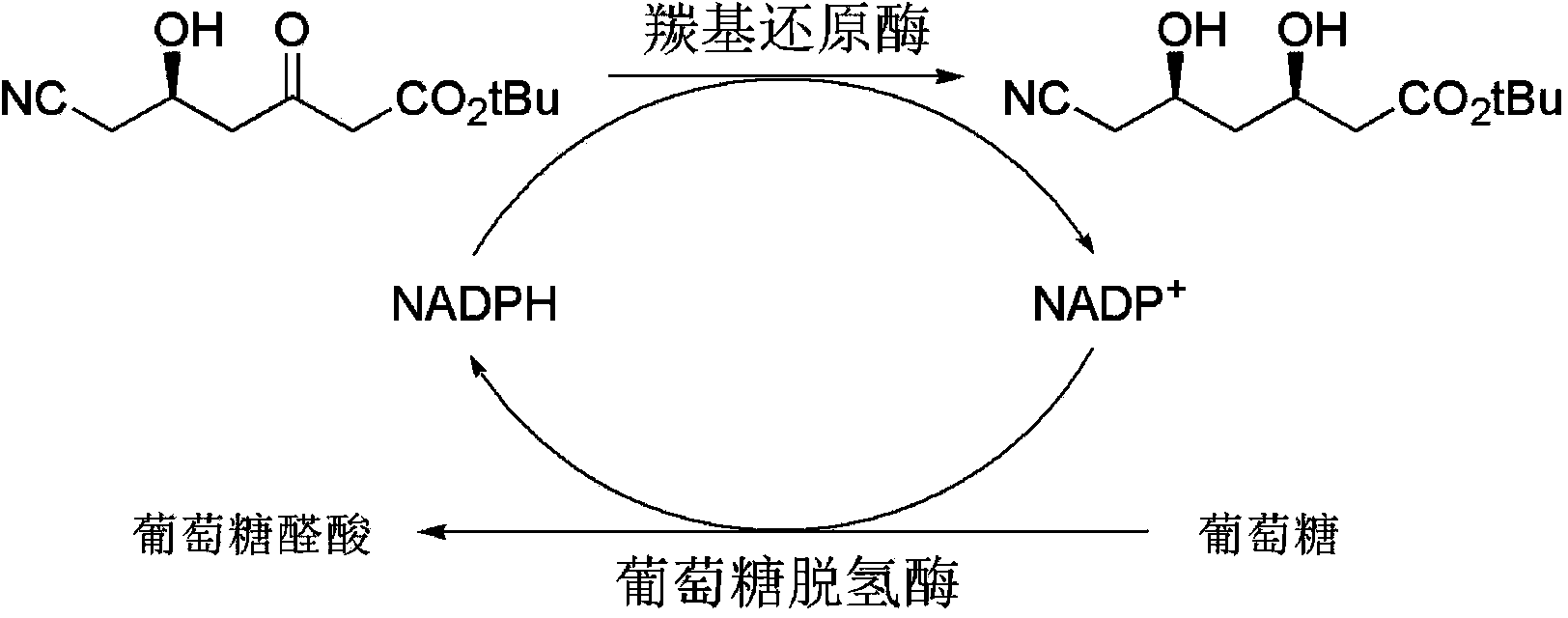

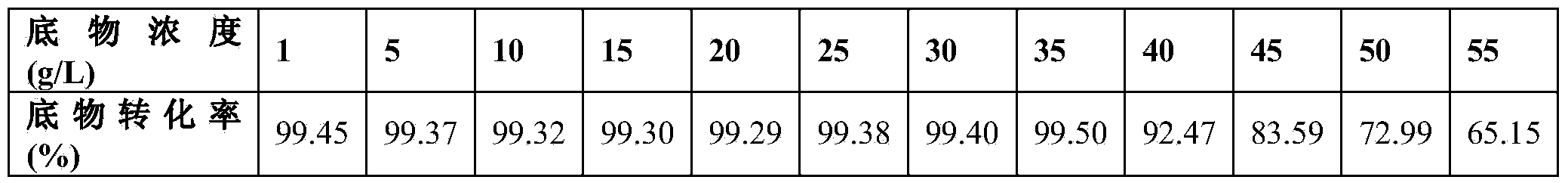

A technology of cyano, tert-butyl hydroxycaproate, applied in microorganism-based methods, biochemical equipment and methods, introduction of foreign genetic material using carriers, etc., can solve the complex preparation process of crude enzyme liquid and the catalytic efficiency of crude enzyme liquid. low cost, hindering large-scale production, etc., to achieve the effect of low price, simplified process, and increased maximum substrate loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

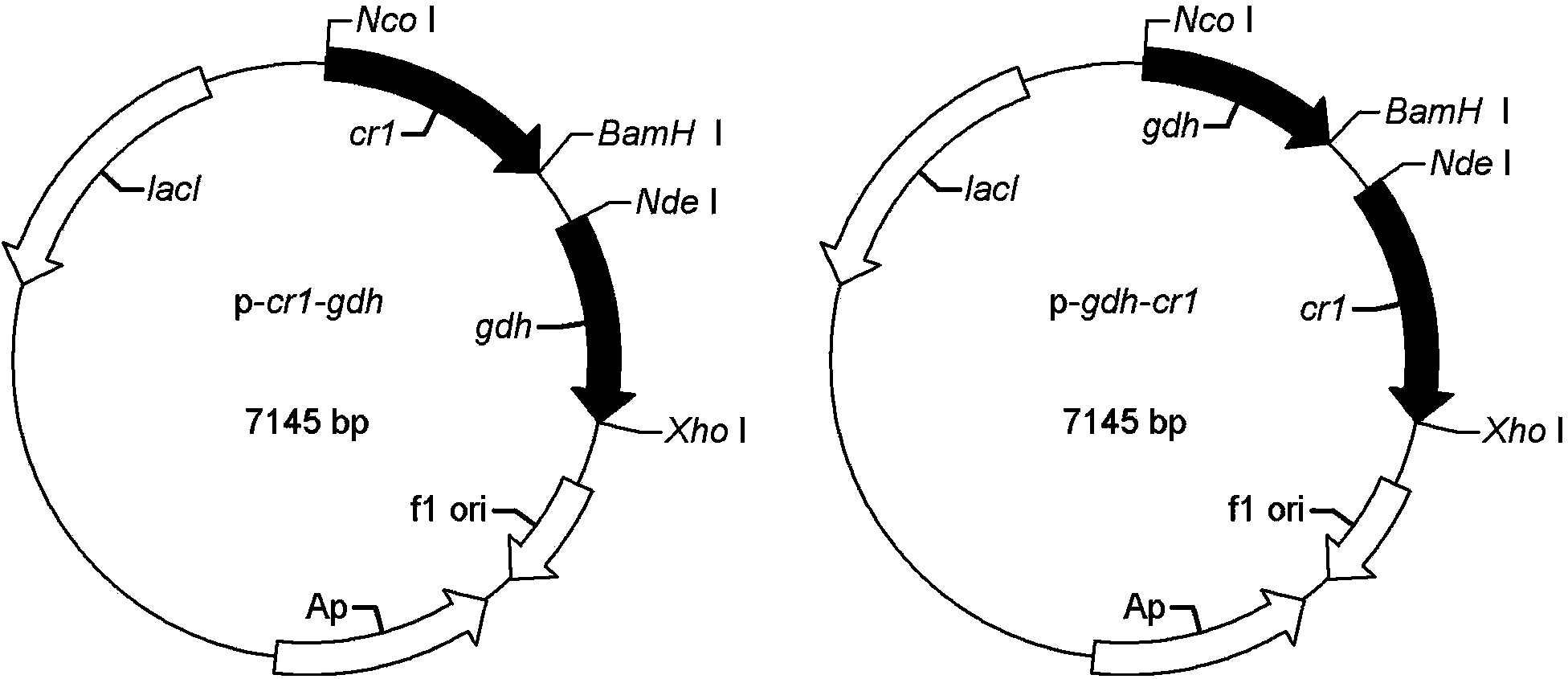

[0033] Construction of Gene Recombinant E. Coli

[0034]The carbonyl reductase gene cr1 from Saccharomyces cerevisiae and the glucose dehydrogenase gene gdh from Bacillus megaterium were fully synthesized, and restriction enzyme endonuclease sites were inserted in the upstream and downstream of the gene sequence: co-expression vector pETDeut-1 No. 1 multiple The restriction sites used to insert foreign genes on the cloning site (MCS1) are Nco I and BamH I sites; the restriction sites used to insert foreign genes on the No. 2 multiple cloning site (MCS2) are Nde I and Xho I. The carbonyl reductase gene and the glucose dehydrogenase gene were respectively inserted into the No. 1 and No. 2 multiple cloning sites (MCS) of the prokaryotic co-expression vector by using the enzyme cutting-ligation method familiar to those skilled in the art. After verification and identification, the positive plasmids were divided into two schemes according to the different gene insertion sites. Sch...

Embodiment 2

[0036] Preparation of Fermentation Broth of Gene Recombinant E.Coli

[0037] The two genetically recombinant E. coli obtained in Example 1 were respectively cultured in 50 mL of LB medium (containing 100 μg / mL ampicillin) at 37° C. overnight with shaking. Add 20 mL of overnight cultured bacterial liquid to 250 mL of LB medium (containing 100 μg / mL ampicillin), and shake at 37°C until the culture medium is OD 600 When = 0.8±0.1, add IPTG with a final concentration of 0.5mM, continue shaking culture at 15-35°C for 16h, and obtain the recombinant E. Coli fermentation broth.

Embodiment 3

[0039] Co-expression of Carbonyl Reductase and Glucose Dehydrogenase at Different Temperatures

[0040] The bacterial cell fermentation broth in Example 2 was centrifuged at 5000*g for 15 minutes to collect the bacterial cells, wherein 8 g / L of wet bacteria was obtained at 15 °C, 11 g / L of wet bacteria at 25 °C, and 13 g / L of wet bacteria at 20 °C. After the cells were collected, potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer was added to resuspend the cells, and the cells were crushed by high pressure at 35kpsi. Centrifuge the crushed bacteria at 15000*g for 20 minutes to obtain the crude enzyme solution. Using 15% SDS-PAGE to test the crude enzyme solution, the two enzymes are normally co-expressed in pGC and pCG, and the molecular weight of the carbonyl reductase CR1 monomer is about 35.5kDa, and the molecular weight of the glucose dehydrogenase GDH monomer is about 28.3kDa .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com