Preparation method of boron nitride nano tube

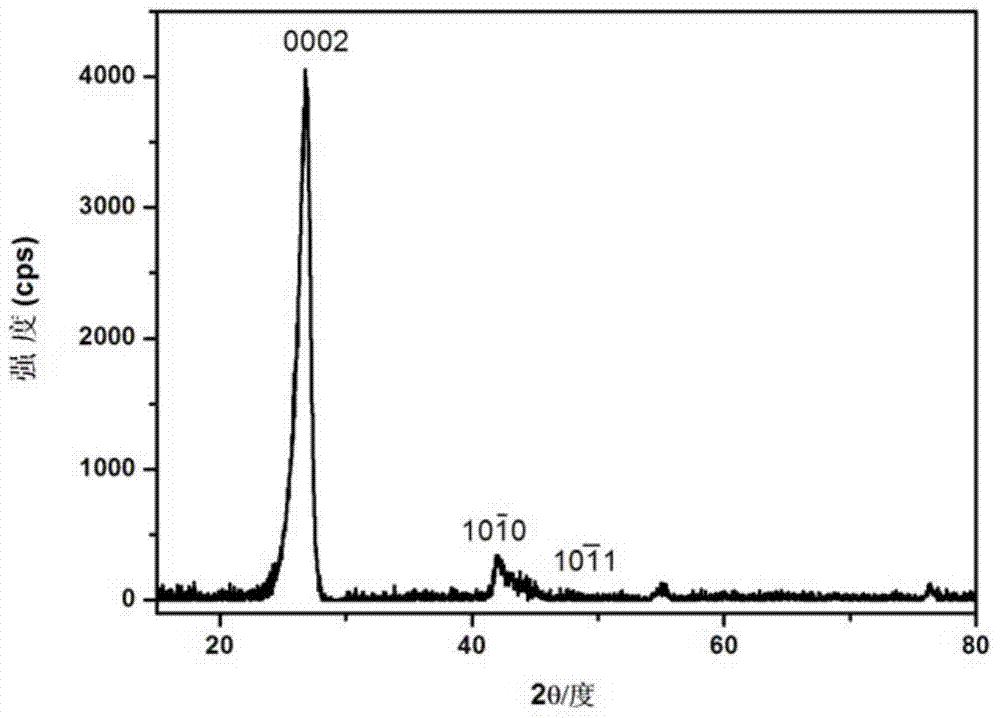

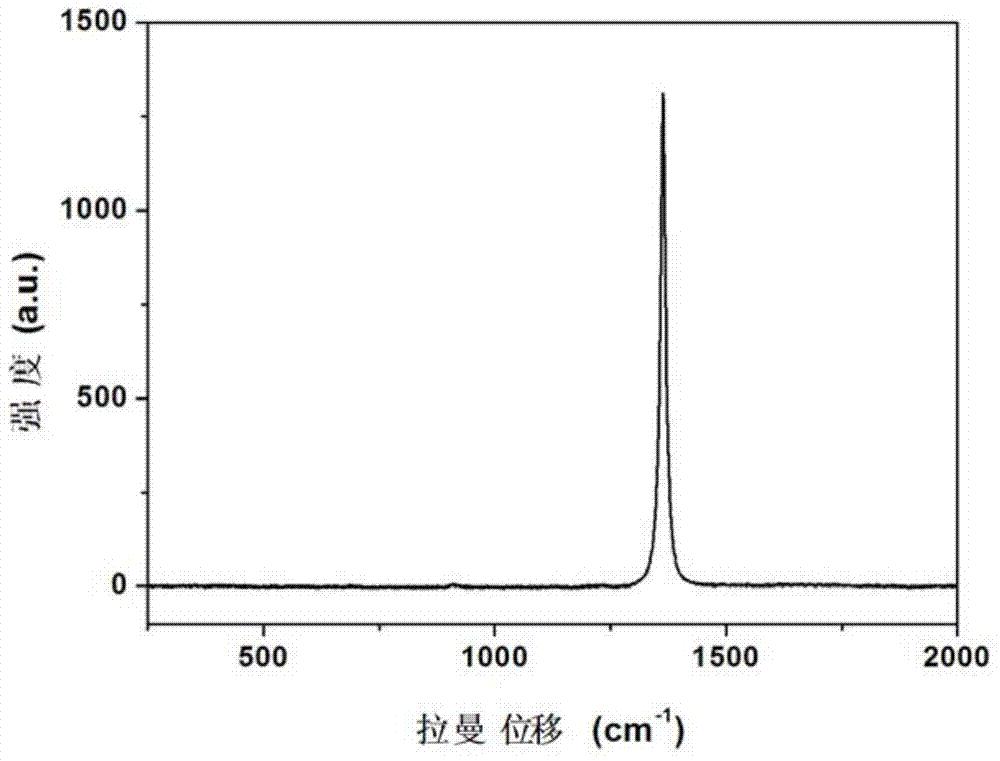

A technology of boron nitride nanotubes and boron oxide, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low product purity, expensive raw materials, and small aspect ratio, and achieve high purity and crystallization The effect of high degree and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix boron oxide and metal magnesium powder according to the molar ratio of 1:1, put them in an agate jar, adopt the method of alternating forward and reverse operation, ball mill for 48 hours, take out, and obtain a uniformly mixed solid powder with a particle size of about 2 -5 microns;

[0029] (2) The solid powder obtained in step (1) was placed in a vertical vacuum radio frequency induction heating furnace, and the temperature was raised in an argon atmosphere at a heating rate of 50° C. per minute, and a gas flow rate of 200 ml / min. When the temperature rose to 1350° C., feed 300 ml / min of ammonia gas, keep warm for 3 hours, and naturally cool down to room temperature in an argon atmosphere with an air velocity of 200 ml / min to obtain a white solid.

[0030] (3) The white solid obtained in step (2) was soaked in 0.1N nitric acid aqueous solution for 5 hours, and then washed 5 times with deionized water.

[0031] (4) Put the white solid obtained in step (4) int...

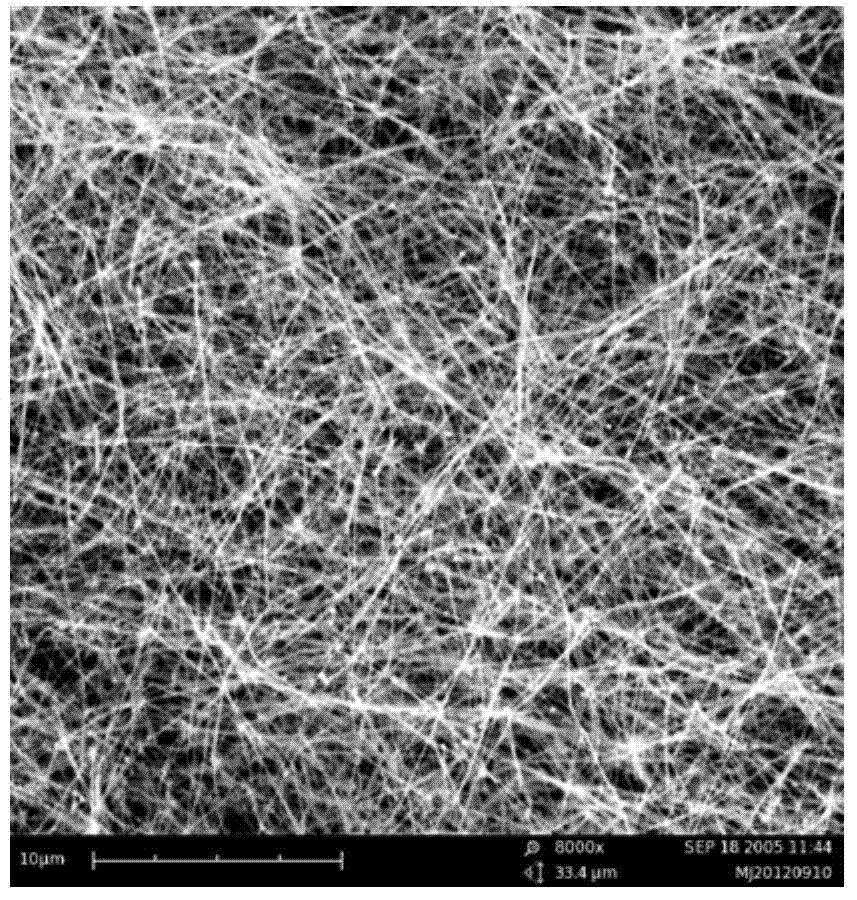

Embodiment 2

[0034] Change the reaction temperature of step (2) in Example 1 to 1500°C, and other operations are the same as in Example 1 to obtain boron nitride nanotubes. SEM analysis shows that the diameter of the obtained boron nitride nanotubes is about 80-100 nanometers, about 10 microns in length, and about 100 aspect ratios.

Embodiment 3

[0036] Change the reaction temperature of step (2) in Example 1 to 1600 ° C, and other operations are the same as in Example 1 to obtain boron nitride nanotubes. SEM analysis shows that the obtained boron nitride nanotubes have a diameter of about 100 nanometers, about 10 microns in length, and an aspect ratio of about 100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com