Laser direct structuring PC/ABScomposite material, preparation method and application thereof

A technology of laser direct forming and composite materials, applied in the field of PC/ABS composite materials and their preparation, can solve the problems of thermal oxidation aging of polymer materials, affecting the service life of products, affecting the effect of electroless plating, etc., and achieves good dispersibility. , Improve the service life and reduce the effect of thermal oxidation aging reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

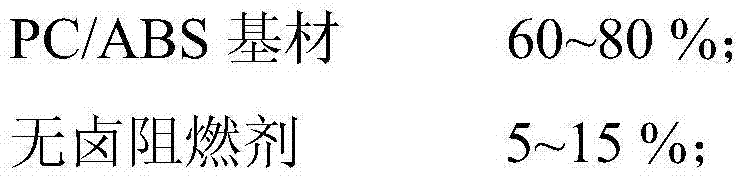

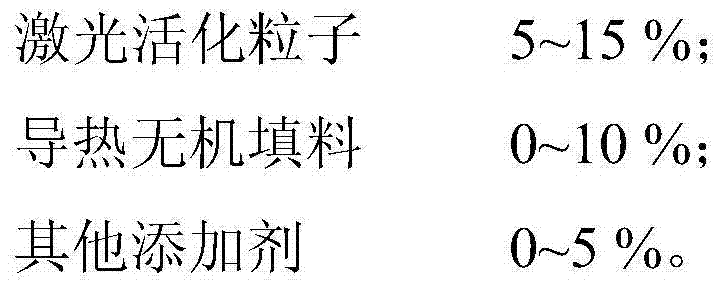

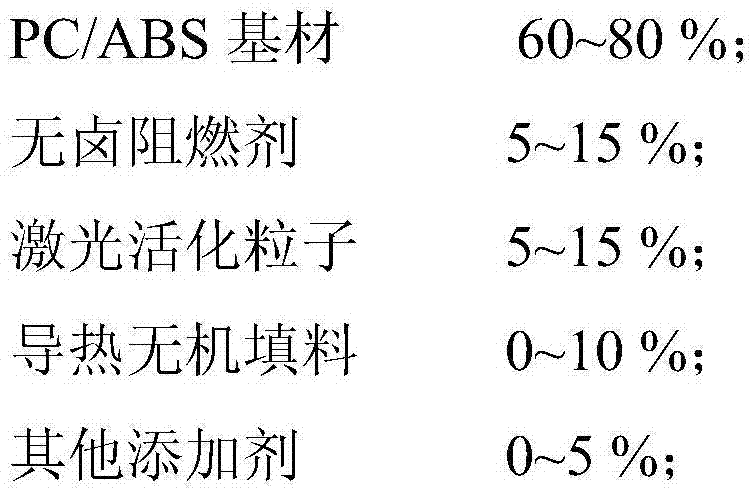

[0047] Embodiment 1: the preparation of the PC / ABS composite material of laser direct forming

[0048] PC / ABS alloy 74wt%, halogen-free flame retardant selection Reofos TPP (triphenylphosphine compound) 10wt%, laser activated particles 5wt%; glass fiber 10wt%; antioxidant (tri[2,4-di-tert-butyl ] phenyl phosphite) 0.5wt%, compatibilizer (ABS-g-MAH) 0.5wt%.

[0049] The preparation of the laser-activated particles: under a nitrogen atmosphere, add the configured acrylate monomer (methyl methacrylate) / 1 L of positive microemulsion composed of dodecyltrimethylammonium bromide / water, wherein the mass ratio of acrylate monomer / dodecyltrimethylammonium bromide / water is 30:5:100. Under the condition of vigorous stirring at room temperature, slowly add nano-copper powder with a concentration of 30wt% (3% of the mass of the acrylate monomer), an initiator (azoisobutyronitrile, 1% of the mass of the acrylate monomer), silane Coupling agent (isobutyl triethoxy silicon, 1% of the mass ...

Embodiment 2

[0051] Embodiment 2: the preparation of the PC / ABS composite material of laser direct molding

[0052] PC / ABS alloy 69wt%, halogen-free flame retardant selection Reofos TPP (triphenylphosphine compound) 10wt%, laser activated particles 10wt%; glass fiber 10wt%; antioxidant (tri[2,4-di-tert-butyl ] phenyl phosphite) 0.5wt%, compatibilizer (ABS-g-MAH) 0.5wt%.

[0053] The preparation of the laser-activated particles: under a nitrogen atmosphere, add the configured acrylate monomer (methyl methacrylate) / 1 L of positive microemulsion composed of dodecyltrimethylammonium bromide / water, wherein the mass ratio of acrylate monomer / dodecyltrimethylammonium bromide / water is 30:5:100. Under the condition of vigorous stirring at room temperature, slowly add nano-copper powder with a concentration of 20wt% (1% of the mass of the acrylate monomer), an initiator (azoisobutyronitrile, 1% of the mass of the acrylate monomer), silane Coupling agent (isobutyl triethoxy silicon, 1% of the mass...

Embodiment 3

[0055] Embodiment 3: the preparation of the PC / ABS composite material of laser direct forming

[0056] PC / ABS alloy 64wt%, halogen-free flame retardant selection Reofos TPP (Dahu Company) 10wt%, laser activated particles 15wt%; glass fiber 10wt%; antioxidant (tris[2,4-di-tert-butyl]phenyl Phosphite) 0.5wt%, compatibilizer (ABS-g-MAH) 0.5wt%.

[0057] Preparation of the laser-activated particles: under a nitrogen atmosphere, add the configured acrylate monomer (propyl methacrylate) / 1 L of positive microemulsion composed of dodecyltrimethylammonium bromide / water, wherein the mass ratio of acrylate monomer / dodecyltrimethylammonium bromide / water is 30:5:100. Under the condition of vigorous stirring at room temperature, the concentration of nano-copper powder is 20wt% (5% of the mass of the acrylate monomer), the initiator (azoisobutyronitrile, 2% of the mass of the acrylate monomer), silane Coupling agent (isobutyl triethoxy silicon, 5% of the mass of acrylate monomer) in isopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com