Laser direct structuring pc/abs composite material and its preparation method and application

A technology of laser direct forming and composite materials, applied in the field of PC/ABS composite materials and their preparation, can solve the problems of affecting the service life of products, thermal-oxidative aging of polymer materials, affecting the effect of electroless plating, etc., so as to improve space utilization efficiency, prolonging service life, and reducing the effect of thermo-oxidative aging reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

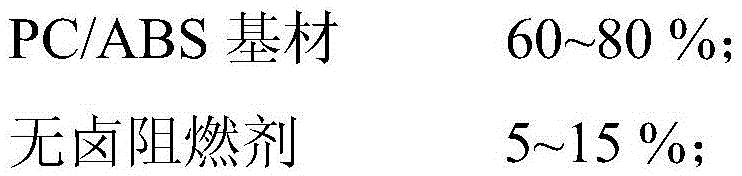

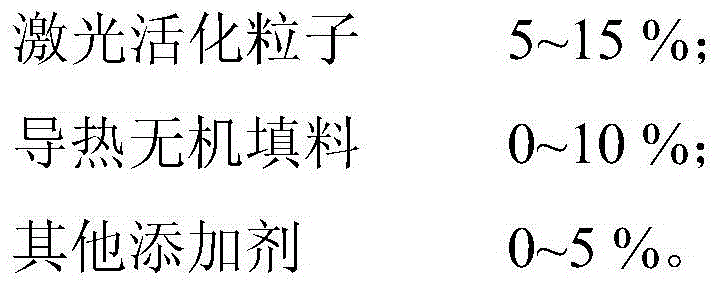

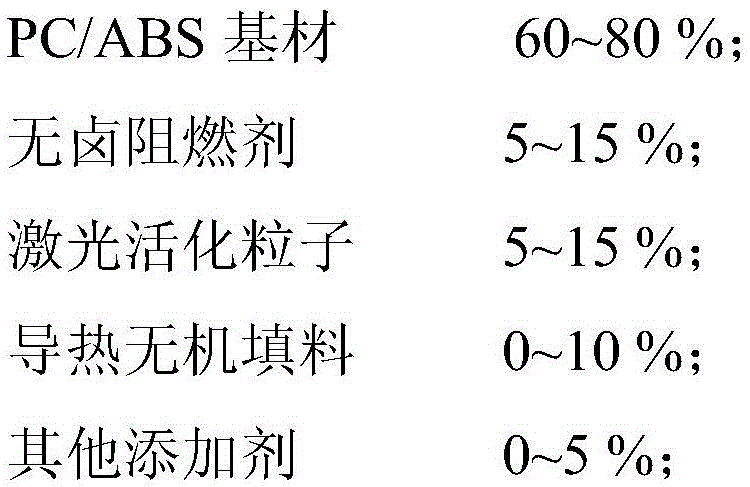

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the preparation of the PC / ABS composite material of laser direct forming

[0048] PC / ABS alloy 74wt%, halogen-free flame retardant selection Reofos TPP (triphenylphosphine compound) 10wt%, laser activated particles 5wt%; glass fiber 10wt%; antioxidant (tri[2,4-di-tert-butyl ] phenyl phosphite) 0.5wt%, compatibilizer (ABS-g-MAH) 0.5wt%.

[0049] The preparation of the laser-activated particles: under a nitrogen atmosphere, add the configured acrylate monomer (methyl methacrylate) / 1 L of positive microemulsion composed of dodecyltrimethylammonium bromide / water, wherein the mass ratio of acrylate monomer / dodecyltrimethylammonium bromide / water is 30:5:100. Under the condition of vigorous stirring at room temperature, slowly add nano-copper powder with a concentration of 30wt% (3% of the mass of the acrylate monomer), an initiator (azoisobutyronitrile, 1% of the mass of the acrylate monomer), silane Coupling agent (isobutyl triethoxy silicon, 1% of the mass ...

Embodiment 2

[0051] Embodiment 2: the preparation of the PC / ABS composite material of laser direct forming

[0052] PC / ABS alloy 69wt%, halogen-free flame retardant selection Reofos TPP (triphenylphosphine compound) 10wt%, laser activated particles 10wt%; glass fiber 10wt%; antioxidant (tri[2,4-di-tert-butyl ] phenyl phosphite) 0.5wt%, compatibilizer (ABS-g-MAH) 0.5wt%.

[0053] The preparation of the laser-activated particles: under a nitrogen atmosphere, add the configured acrylate monomer (methyl methacrylate) / 1 L of positive microemulsion composed of dodecyltrimethylammonium bromide / water, wherein the mass ratio of acrylate monomer / dodecyltrimethylammonium bromide / water is 30:5:100. Under the condition of vigorous stirring at room temperature, slowly add nano-copper powder with a concentration of 20wt% (1% of the mass of the acrylate monomer), an initiator (azoisobutyronitrile, 1% of the mass of the acrylate monomer), silane Coupling agent (isobutyl triethoxy silicon, 1% of the mass...

Embodiment 3

[0055] Embodiment 3: the preparation of the PC / ABS composite material of laser direct forming

[0056] PC / ABS alloy 64wt%, halogen-free flame retardant selection Reofos TPP (Dahu Company) 10wt%, laser activated particles 15wt%; glass fiber 10wt%; antioxidant (tris[2,4-di-tert-butyl]phenyl Phosphite) 0.5wt%, compatibilizer (ABS-g-MAH) 0.5wt%.

[0057] Preparation of the laser-activated particles: under a nitrogen atmosphere, add the configured acrylate monomer (propyl methacrylate) / 1 L of positive microemulsion composed of dodecyltrimethylammonium bromide / water, wherein the mass ratio of acrylate monomer / dodecyltrimethylammonium bromide / water is 30:5:100. Under the condition of vigorous stirring at room temperature, the concentration of nano-copper powder is 20wt% (5% of the mass of the acrylate monomer), the initiator (azoisobutyronitrile, 2% of the mass of the acrylate monomer), silane Coupling agent (isobutyl triethoxy silicon, 5% of the mass of acrylate monomer) in isopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com