Organic electroluminescence apparatus and preparation method thereof

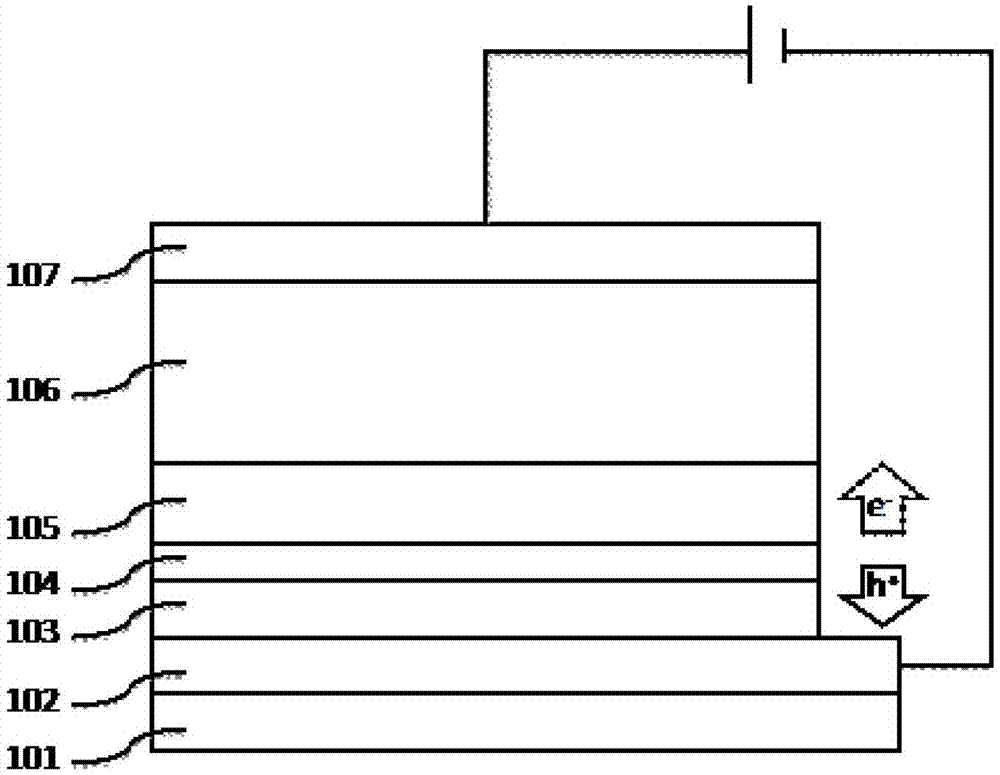

An electroluminescence device and luminescence technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of affecting the packaging stability, poor luminous effect, and low luminous efficiency, so as to improve electron injection efficiency and improve Effect of recombination probability, luminous quantum efficiency, and high luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

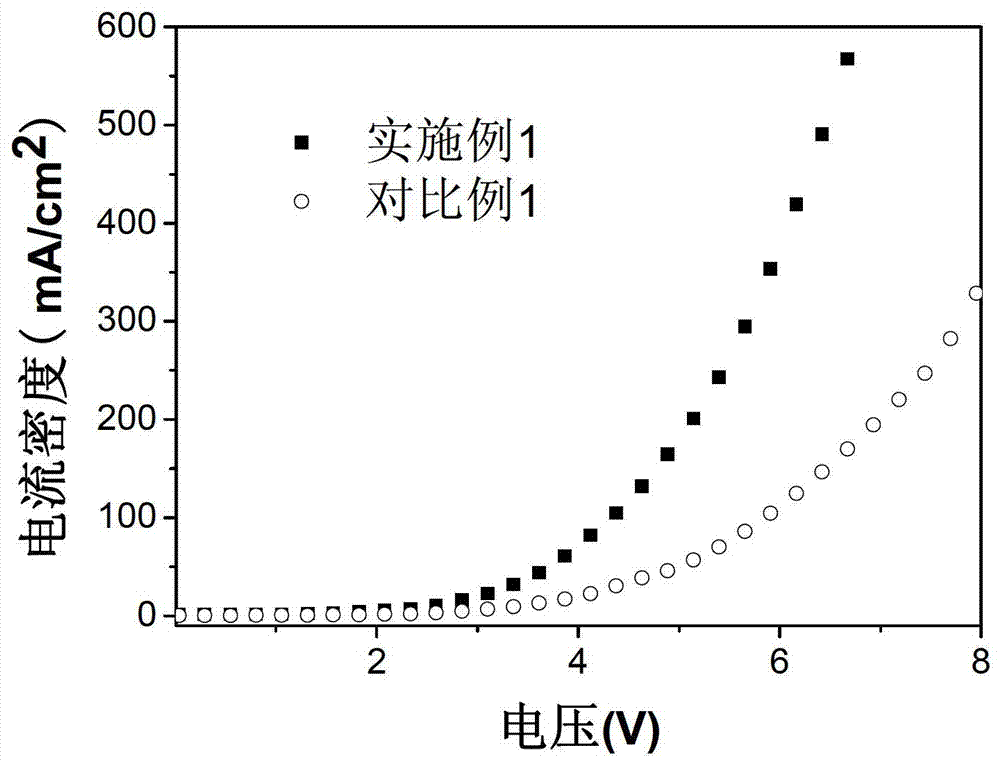

Embodiment 1

[0080] A method for preparing an organic electroluminescent device, comprising the steps of:

[0081] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0082] In a vacuum of 1×10 -4 In Pa's vacuum coating system, the indium tin oxide film (ITO) is prepared as the cathode on the surface of the glass substrate by sputtering at a speed of 0.1nm / s;

[0083] Through thermal evaporation process, in a vacuum of 1.0×10 -4 Under the conditions of Pa and speed of 0.02nm / s, Au and WO were sequentially evaporated 3 , Al to prepare the pn junction layer; then through the thermal evaporation process, in a vacuum of 1.0×10 -4 Sequential evaporation of Li under the conditions of Pa and speed 0.02nm / s 2 CO 3 According to the doping mass fraction of 10% doped to Alq 3 The mixed material formed in , TPBi, C545T is doped to Alq accor...

Embodiment 2

[0087] A method for preparing an organic electroluminescent device, comprising the steps of:

[0088] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0089] In a vacuum of 1×10 -5 In Pa's vacuum coating system, aluminum-zinc oxide film (AZO) was sputtered on the surface of the glass substrate at a speed of 1nm / s as the cathode;

[0090] Through thermal evaporation process, in a vacuum of 1.0×10 -5 Under the conditions of Pa and speed of 0.5nm / s, Cu and ReO are sequentially evaporated 3 , Ag to prepare the pn junction layer; then through the thermal evaporation process, in a vacuum of 1.0×10 -5 Sequential evaporation of Cs under the conditions of Pa and speed 0.5nm / s 2 CO 3 The mixed material, BAlq, DCJTB formed by doping Bphen according to the doping mass fraction of 5% is doped into Alq according to the doping m...

Embodiment 3

[0093] A method for preparing an organic electroluminescent device, comprising the steps of:

[0094] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0095] In a vacuum of 1×10 -3 In Pa's vacuum coating system, a gallium zinc oxide film (GZO) is prepared as a cathode on the surface of a glass substrate by sputtering at a speed of 0.5nm / s;

[0096] Through thermal evaporation process, in a vacuum of 1.0×10 -3 Under the conditions of Pa and speed of 0.2nm / s, Pt and MoO were sequentially evaporated 3 , Mg to prepare the pn junction layer; then through the thermal evaporation process, in a vacuum of 1.0×10 -3 Sequential evaporation of CsN under the conditions of Pa and speed 0.2nm / s 3 The mixed material formed by doping PBD according to the doping mass fraction of 15%, the mixed material formed by doping BAlq and Ir(p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com