Method for preparing pollen nutrient solution by ultrasonic and pulse electric field

A technology of pulsed electric field and high-voltage pulsed electric field, which is applied in food preparation, food ultrasonic treatment, and pharmaceutical formulations. The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

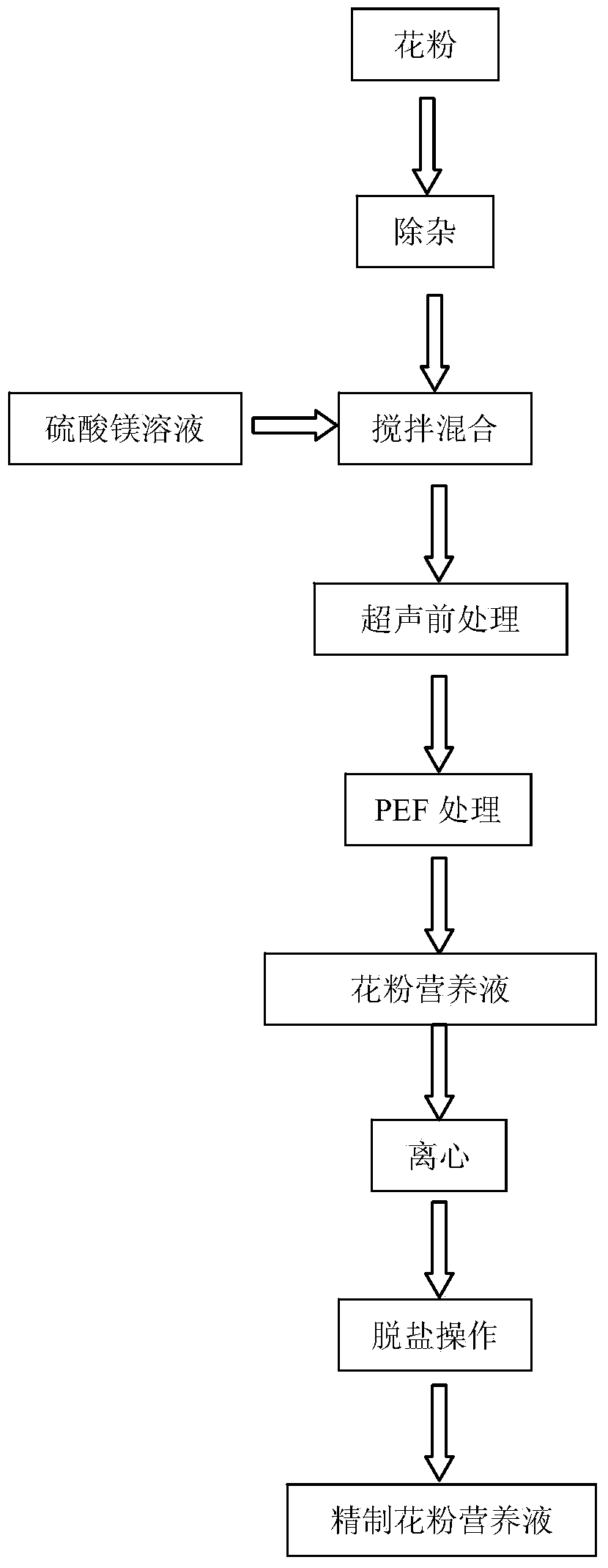

Method used

Image

Examples

Embodiment 1

[0032] Weigh out 500g of Qinghai-Tibet high crude oil cauliflower pollen. Mix pollen with 1mol / L magnesium sulfate (food grade) solution uniformly to obtain a pollen solution. The mass ratio of pollen: magnesium sulfate solution is 1:20, the mixing time is 10min, the temperature is 60℃, and the stirring speed is 1000r / min. . The pollen solution is pre-treated with ultrasonic (SB-25-12D ultrasonic cleaning machine, Ningbo Xinzhi Biotechnology Co., Ltd.). The ultrasonic treatment conditions are temperature 60℃, ultrasonic frequency 800W, and ultrasonic treatment time 10min. The pollen solution after ultrasonic pretreatment is processed by high-voltage pulsed electric field (South China University of Technology and Food Development), and the pollen solution is transported to the high-voltage pulsed electric field by a liquid pump. The processing conditions are: temperature 60℃, electric field intensity 10kV / cm, The pulse waveform is a square wave, the pulse width is 10 μs, and th...

Embodiment 2

[0034] Weigh 100g of the cleaned Qinghai-Tibet high crude oil rape pollen, mix the pollen with a 0.5mol / L magnesium sulfate (food grade) solution evenly to obtain a pollen solution; wherein the mass ratio of pollen: magnesium sulfate solution is 1:10, and the mixing time 5min, temperature is 40℃, stirring speed is 500r / min. The pollen solution was subjected to ultrasonic pretreatment process (same as Example 1). The ultrasonic treatment conditions were temperature 40°C, ultrasonic frequency 600W, and ultrasonic treatment time 5min. The pollen solution after ultrasonic pretreatment was treated with high-voltage pulsed electric field (same as Example 1). The treatment conditions were: temperature 40°C, electric field intensity 10kV / cm, pulse waveform as square wave, pulse width 5μs, pulse frequency 400Hz, sample The number of receiving electric pulse treatment is 5000, and the above-mentioned high-voltage pulse electric field treatment is cycled twice. The treated pollen solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com