Polyaniline derivative-loaded salen catalyst as well as preparation method and application of catalyst

A technology of derivatives and polyaniline, which is applied in the field of preparation of new polymer-supported catalysts, can solve the problems of difficult separation of products and reactants, unsatisfactory cycle times, and low reaction catalytic efficiency, achieving low cost and good catalytic performance. Effect, synthesis method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

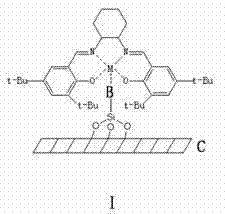

[0030] Example 1: The structural formula of the polyaniline derivative supported salen catalyst is shown in formula I:

[0031] I

[0032] In the catalyst, M is chromium (Cr), A is a salen catalyst, B is 3-aminopropyltriethoxysilane, and C is a hydroxyl-containing polyaniline derivative.

[0033] The preparation method of the polyaniline derivative loaded salen catalyst in this embodiment is as follows:

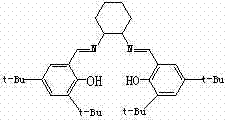

[0034] (1) Synthesis of hydroxyl-containing polyaniline derivatives

[0035] Prepare 100ml of liquid A and liquid B in a beaker with water as a solvent. Liquid A contains 6mol / L hydrochloric acid and 3.36 mol / L ammonium persulfate; liquid B contains 2.4 mol / L aniline, 0.168mol / L of o-aminophenol, 6mol / L of hydrochloric acid; under the action of magnetic stirring, respectively stir liquid A and liquid B evenly, slowly add liquid A to liquid B and stir for 6 hours at a temperature of 26°C, then use...

Embodiment 2

[0046] Example 2: The structural formula of the polyaniline derivative supported salen catalyst is shown in formula I:

[0047]

[0048] I

[0049] In the catalyst, M is one of chromium (Cr), A is a salen catalyst, B is gamma-aminopropyltrimethoxysilane, and C is a hydroxyl-containing polyaniline derivative.

[0050] The preparation method of the polyaniline derivative loaded salen catalyst in this embodiment is as follows:

[0051] (1) Synthesis of hydroxyl-containing polyaniline derivatives

[0052] Prepare 100ml of liquid A and liquid B in a beaker with water as a solvent. Liquid A contains 8mol / L sulfuric acid and 3.36mol / L ammonium persulfate; liquid B contains 1.2mol / L aniline and 0.336mol / L o-aminophenol and 8mol / L sulfuric acid. Stir liquid A and liquid B separately under the action of magnetic stirring, slowly add liquid A to liquid B and stir for 6 hours at a temperature of 26°C, then alternately wash with 0.03mol / L HCl and distilled water until colorless ,...

Embodiment 3

[0064] Example 3: The structural formula of the polyaniline derivative supported salen catalyst is shown in formula I:

[0065] Formula Ⅰ

[0066] In the catalyst, M is cobalt (Co), A is a salen catalyst, B is N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane, and C is a hydroxyl-containing polyaniline derivative.

[0067] The preparation method of the polyaniline derivative loaded salen catalyst in this embodiment is as follows:

[0068] (1) Synthesis of hydroxyl-containing polyaniline derivatives

[0069] Use water as a solvent and configure 100ml of liquid A and liquid B in a beaker, wherein liquid A contains 6mol / L nitric acid and 2.525mol / L ammonium persulfate, and liquid B contains 0.8mol / L aniline, 0.503mol / L of o-aminophenol and 6mol / L of nitric acid, stir liquid A and liquid B respectively under the action of magnetic stirring, slowly add liquid A to liquid B and stir for 7 hours at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com